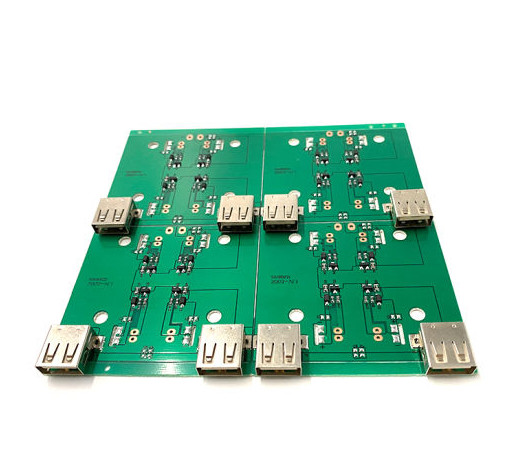

Aluminum substrate PCB circuit board

Aluminum substrate PCB circuit board

Introduce the advantages and disadvantages of ceramic PCB circuit boards. One of the disadvantages is that the ceramic substrate is too expensive and fragile. Ordinary glass fiber PCBs have poor heat dissipation, ceramic PCBs are relatively stable, and are not easy to deform in high temperature and high humidity environments, but they are more expensive and are often used in high-end products. If my product is not so high-end, such as a large-area and high-power LED light board, which is relatively cheap, but requires very good heat dissipation performance, is there a PCB substrate that is cheap and has good heat dissipation?

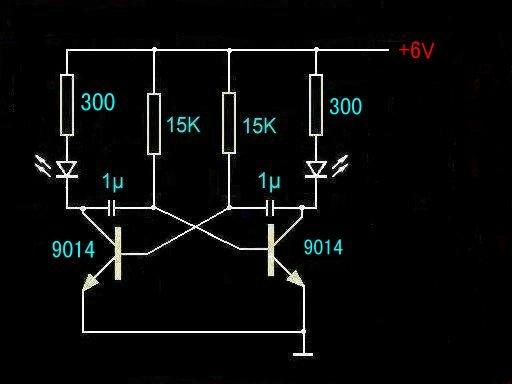

The answer is yes. That is the aluminum substrate PCB to be introduced in this article. Everyone knows that aluminum is a metal with electrical conductivity. How can it be used as a PCB material?

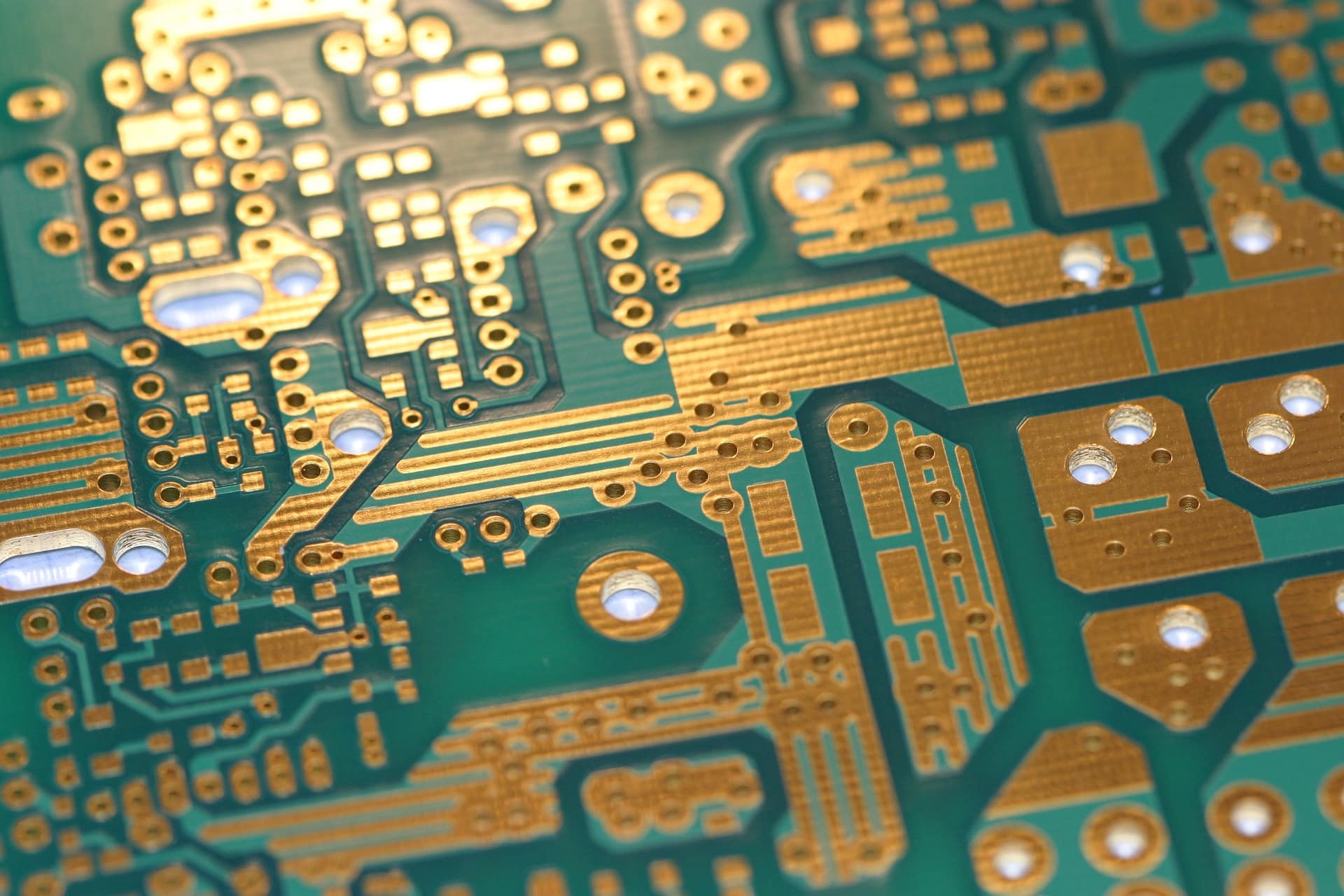

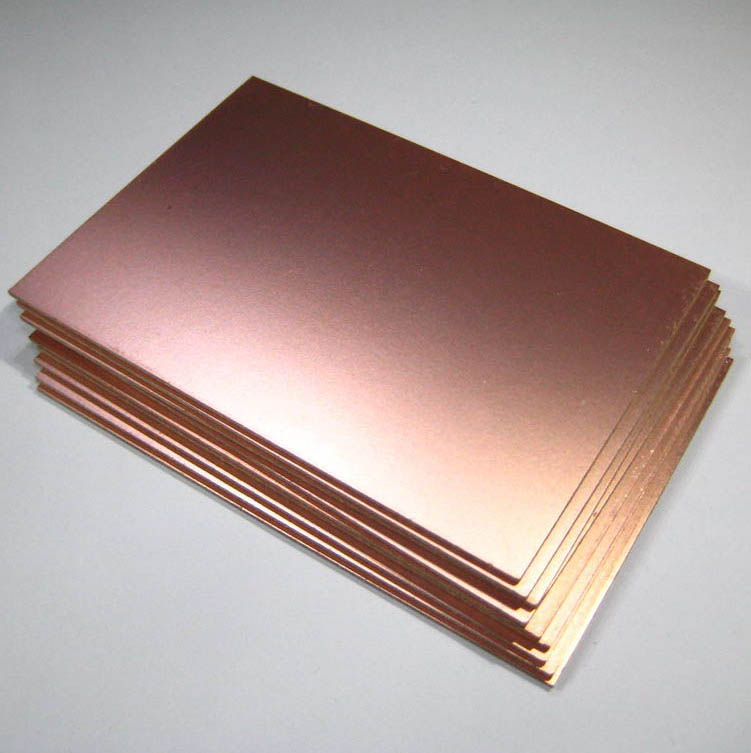

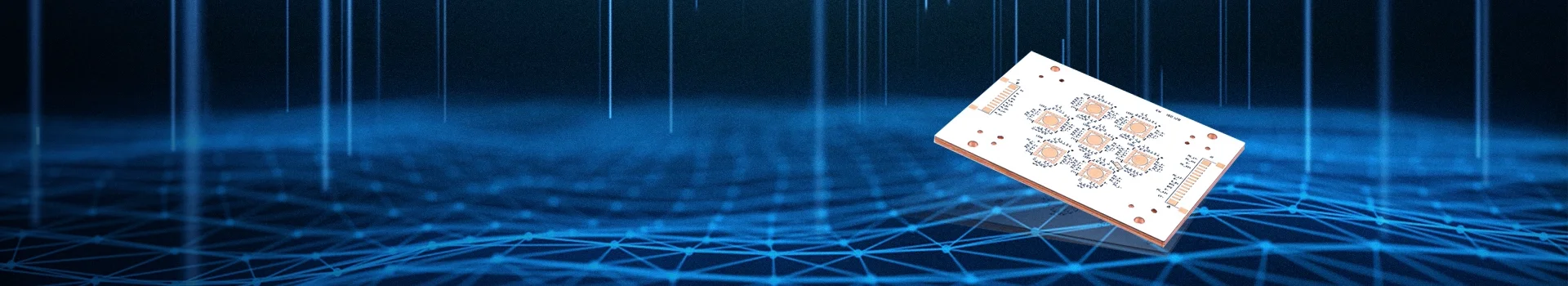

This is because the aluminum substrate consists of a three-layer structure, namely: copper foil, insulating layer and metal aluminum. Since there is an insulating layer, can other materials be used for the metal layer besides aluminum? Such as copper plate, stainless steel, iron plate, silicon steel plate, etc. Which material to use for the metal substrate, in addition to considering the heat dissipation performance, the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface state and cost of the metal substrate should also be considered.

In general, aluminum plates are an ideal choice in terms of cost and technical performance. Available aluminum plates are 6061, 5052, 1060 and so on. If there are requirements for higher thermal conductivity, mechanical properties, electrical properties and other special properties, copper plates, stainless steel plates, iron plates and silicon steel plates can also be used.

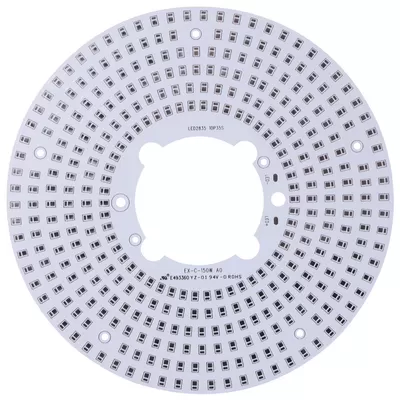

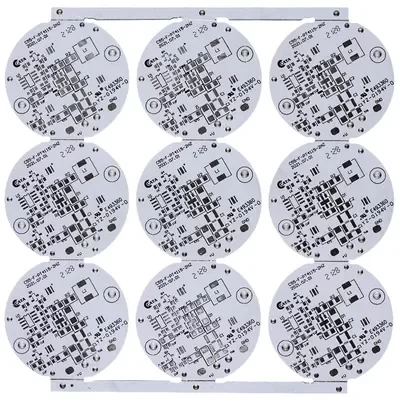

Commonly used in LED lighting products, there are two sides, the white side is soldered to the LED pins, and the other side shows the natural color of aluminum, and is usually coated with heat-conducting gel and then in contact with the heat-conducting part. It is mainly used in LED lamps, audio equipment, power supply equipment, etc. The main advantage is fast heat conduction and good heat dissipation performance.

Compared with the traditional FR-4, the aluminum substrate can minimize the thermal resistance, so that the aluminum substrate has excellent thermal conductivity; compared with the ceramic substrate, its mechanical properties are extremely good.

In addition to good heat dissipation performance, aluminum substrates also have the following advantages:

Comply with RoHS environmental protection requirements

More suitable for SMT process

Higher current carrying capacity

In the circuit design scheme, heat dissipation is handled extremely effectively, thereby reducing the operating temperature of the module, prolonging the service life, and improving power density and reliability;

Reduce the assembly of radiators and other hardware (including thermal interface materials), reduce product volume, reduce hardware and assembly costs; optimize the combination of power circuits and control circuits;

Replace fragile ceramic substrates for better mechanical durability.

Compared with ordinary FR-4 plates, aluminum substrates have one of the biggest advantages that they can carry higher currents. Like FR-4, the circuit layer is connected by copper foil as a wire. Compared with the traditional FR-4, with the same thickness and the same line width, the aluminum substrate can carry higher current.

The core technology of the aluminum substrate is the insulating layer material in the middle, which mainly plays the functions of adhesion, insulation and heat conduction. The aluminum substrate insulation layer is the largest thermal barrier in the power module structure. The better the thermal conductivity of the insulating layer, the more conducive to the diffusion of heat generated during device operation, and the more conducive to reducing the operating temperature of the device, so as to achieve the purpose of increasing the power load of the module, reducing the volume, prolonging the life, and improving the power output. . While satisfying good thermal conductivity, it must also have high-voltage insulation capabilities.

The difference with FR-4 sheet

heat dissipation

The biggest difference between aluminum-based copper-clad laminates and conventional FR-4 copper-clad laminates is heat dissipation. Compared with aluminum-based copper-clad laminates with a thickness of 1.5mm, FR-4 copper-clad laminates have a thermal resistance of 20~22 ℃ for the former and 1.0~2.0 for the latter. ℃, the latter is much smaller.

Thermal expansion coefficient

Because the general FR-4 has the problem of thermal expansion, that is, high temperature will lead to changes in the thickness and flatness of the plate, especially the thermal expansion in the thickness direction of the plate, which will affect the quality of metallized holes and circuits. The main reason for this is that the thermal expansion coefficient in the thickness direction of the raw material of the plate is different: the thermal expansion coefficient of copper is 17×106cm/cm°C, and the base material of FR-4 plate is 110×106cm/cm°C. There is a large difference between the two, which is prone to thermal expansion effect. The thermal expansion coefficient of the aluminum substrate is 50×106cm/cm℃, which is smaller than the general FR-4 plate and closer to the thermal expansion coefficient of copper foil. This is conducive to ensuring the quality and reliability of the printed circuit board.

The main purpose

FR-4 boards are suitable for general circuit design and general electronic products. Aluminum substrates are suitable for circuits with special requirements. Such as: thick film hybrid integrated circuit, heat dissipation of power supply circuit, heat dissipation and cooling of components in the circuit, large-scale substrate that is difficult for ceramic substrate, and circuit whose reliability cannot be solved by using ordinary heat sink.

Machinability

Aluminum substrate has high mechanical strength and toughness, which is better than FR-4 board. For this reason, large-area printed boards can be manufactured on aluminum substrates, and heavy components can be installed on such substrates.

electrical properties

From the comparison between the aluminum substrate and the FR-4 board, due to the high heat dissipation of the metal substrate, the fuse current of the wire is significantly improved, which shows the high heat dissipation characteristics of the aluminum substrate from another angle. The heat dissipation of its aluminum substrate is related to its insulating layer thickness and thermal conductivity. The thinner the insulating layer, the higher the thermal conductivity of the aluminum substrate (but the lower the withstand voltage performance). In order to ensure the performance of electronic circuits, some components in electronic products need to prevent radiation and interference of electromagnetic waves. The aluminum substrate can act as a shielding plate to shield electromagnetic waves.

Insulation properties

Under normal conditions, the withstand voltage value of the aluminum substrate is determined by the thickness of the insulating layer. The withstand voltage value of the aluminum substrate is generally around 500v. If you need to test the withstand voltage value of the aluminum substrate of the LED fluorescent lamp, only It is enough to perform a high voltage test on the input port shell. The value of UL and CE certification should be 2500V, and the value of 3C certification should be 3750V.

Classification of aluminum substrate

Aluminum base copper clad laminates are divided into three categories:

General-purpose aluminum-based copper clad laminate, the insulating layer is composed of epoxy glass cloth bonding sheet;

High heat dissipation aluminum base copper clad laminate, the insulating layer is made of high thermal conductivity epoxy resin or other resins;

Aluminum-based copper-clad laminates are used for high-frequency circuits, and the insulating layer is composed of polyolefin resin or polyimide resin glass cloth bonding sheet.

The main purpose

Lighting products, high-power LED lighting products.

Audio equipment, preamplifiers, power amplifiers, etc.

Power supply equipment, DC/AC converter, rectifier bridge, solid state relay, etc.

Communication products, high-frequency amplifiers, filter appliances, and sending circuits.

- Previous:Plant lamp PCB

- Next:No