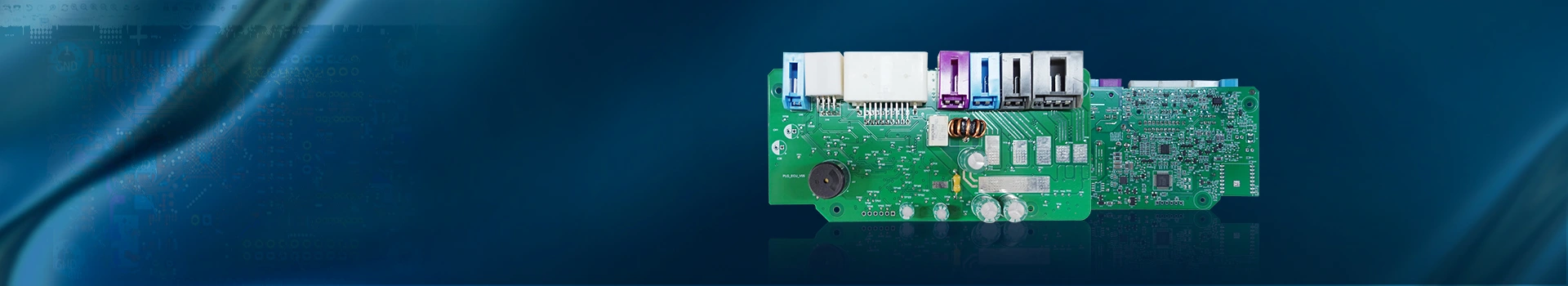

Automotive Electronics Turnkey PCB Assembly

PCB Assembly Name:Automotive Electronics Turnkey PCB Assembly

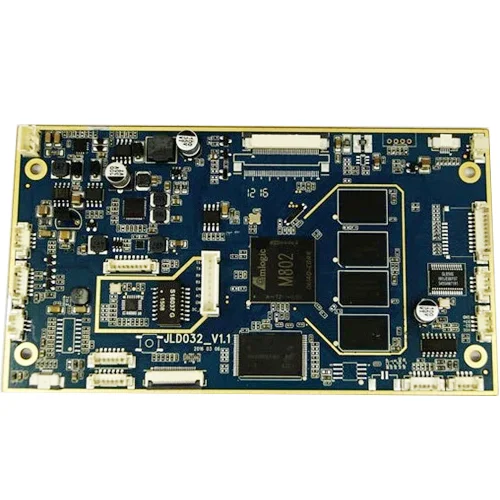

Surface Finishing:HASL, Enig, OSP, Immersion Au, AG, Sn

PCBA-Testing:X-ray, Aoi

Flame Retardant Properties:V0

Processing Technology:Electrolytic Foil

Insulation Materials:Organic Resin

Material:Complex

Applicaton:Industrial PCB PCBA

Transport Package:Packed in Carton

Specification:Copper

Layer:1-18 Layer

Copper Thickness:0.5oz-6oz

Board Thickness:0.2mm-4mm

Min.Hole Size:0.1mm (4 Mil)

Min.Line Spacing:0.1mm (4 Mil)

PCBA QC:X-ray, Aoi Test, Function Test(100% Test)

Specialised:Consumer, LED, Medical, Industrial, Control Board

Delivery:PCB, 7-10 Days;PCBA, 2-3weeks

Service:PCBA/PCB Assembly/PCB Circuit Board

Other Service:PCB/PCB Layout and Design, Engineering Support

Our SMT PCB PCBA manufacture:

2. One-stop solution for various SMT DIP PCB assembly.

3. Professional PCB Board engineer for one-to-one service.

3. 100% PCBA AOI tested guarantee before shipping

4. RoHS, UL, ISO, SGS certificate approved

5. Factory production Capability of 30000 sqm/month

6. Turnkey EMS (electronics manfacturing service) including pcb manufacturing, compoments sourcing, pcb assembly, pcba conformal coating, box build, PCBA function testing.

7. Excellent Customer Service to Meet Your Special Needs

8. Shipment on time.

PCBs We Can Make:

1) We do PCB from double side up to 30-layer Multilayer PCB, HDI jobs.2) If you have repeat orders from other suppliers, and you want to transfer to Intech, we can accept FREE OF TOOLING.

3) Except excellent quality and professional service, we also pay every detail for our customers, for example package to use Desiccant packs & moisture indicator in vacuum-sealed pack to protect PCB.

4) Material: We have FR4 TG135/TG158/TG180 normal material in stock, also have FR1/ FR2/ FR3/ CEM1/ CEM3/ ROGERS/ ARLON/ ISOLA.

5) Rigid / flex/ flex-rigid PCBs with UL approved.

6) Flexible,quickly feedback for customers always.

7) Quickly offer will be less then 4 hours, Some top urgent inquiry we can offer within 1hour.

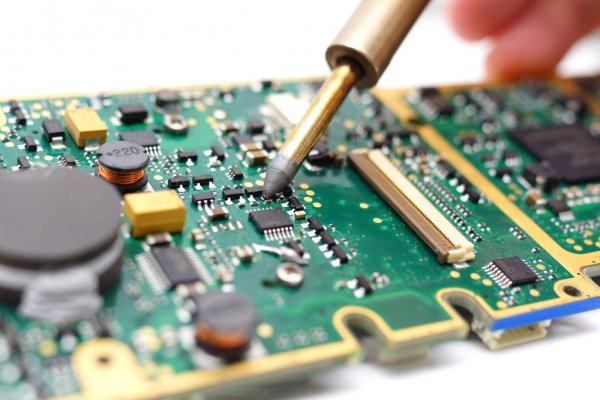

Testing Procedures For PCB PCBA assembling:

We perform multiple quality assuring procedures before shipping out any PCB board. These include:

Visual Inspection

Flying probe, fixture tool

Impedance control

Solder-ability detection

Digital metallographic microscope

AOI (Automated Optical Inspection)

We are a professional PCBA one-stop assembly factory, Kingford supports Automotive Electronics Turnkey PCB Assembly business, welcome to place an order

PCB Assembly Name:Automotive Electronics Turnkey PCB Assembly

Surface Finishing:HASL, Enig, OSP, Immersion Au, AG, Sn

PCBA-Testing:X-ray, Aoi

Flame Retardant Properties:V0

Processing Technology:Electrolytic Foil

Insulation Materials:Organic Resin

Material:Complex

Applicaton:Industrial PCB PCBA

Transport Package:Packed in Carton

Specification:Copper

Layer:1-18 Layer

Copper Thickness:0.5oz-6oz

Board Thickness:0.2mm-4mm

Min.Hole Size:0.1mm (4 Mil)

Min.Line Spacing:0.1mm (4 Mil)

PCBA QC:X-ray, Aoi Test, Function Test(100% Test)

Specialised:Consumer, LED, Medical, Industrial, Control Board

Delivery:PCB, 7-10 Days;PCBA, 2-3weeks

Service:PCBA/PCB Assembly/PCB Circuit Board

Other Service:PCB/PCB Layout and Design, Engineering Support