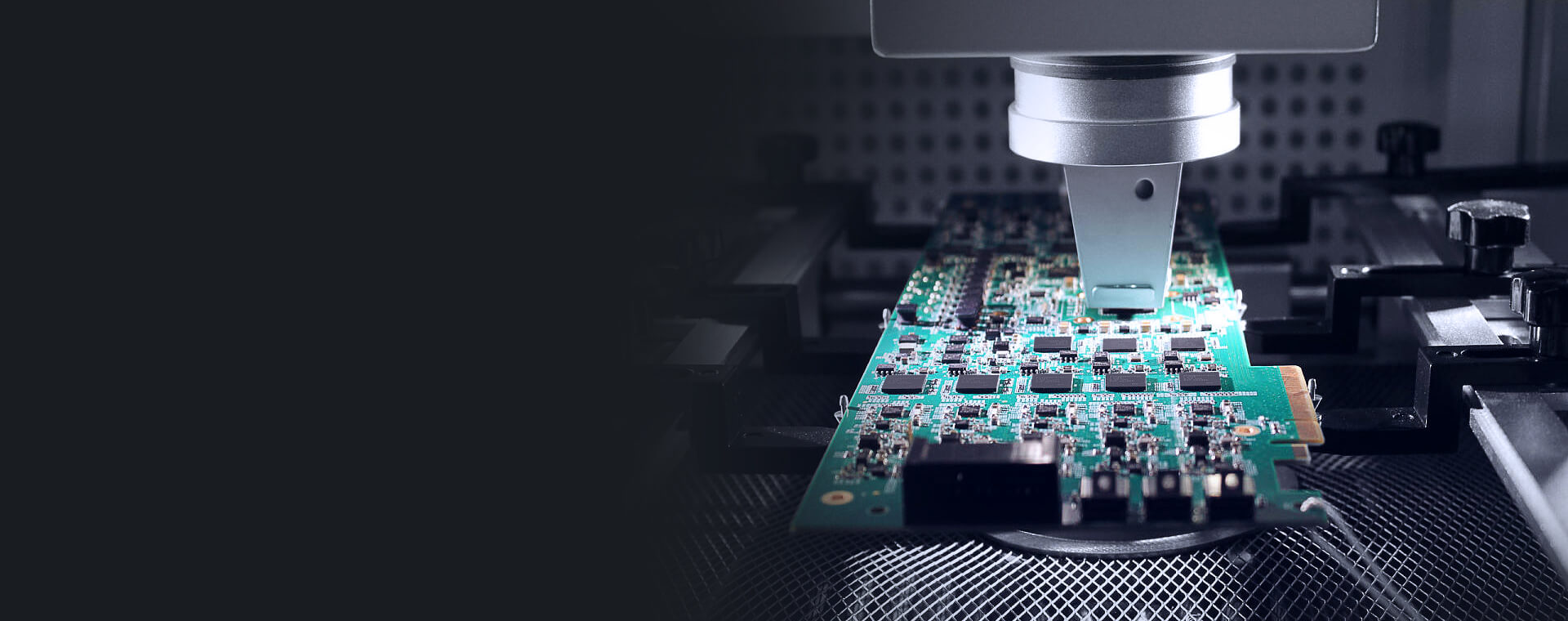

Why Outsource Electronic Component Sourcing?

With the refinement of the industrial division of labor, more and more electronic product R&D companies streamline their organizational structure and allocate limited resources to the two core competitiveness of R&D and sales, thus outsourcing the tedious manufacturing process. Under the trend, it is bound to increase the demand for PCBA labor and materials. Customers only need to provide design documents to allow electronics manufacturers to purchase electronic components and complete the PCBA manufacturing process according to the design requirements. This mode of contracting labor and materials saves the cost of personnel and sluggish costs for the customer's self-built materials procurement, inspection and warehousing. From the overall On the contrary, it will save the total cost of the customer enterprise and improve the turnover efficiency of finance and products.

How can we ensure that the purchase of electronic components is a genuine channel?

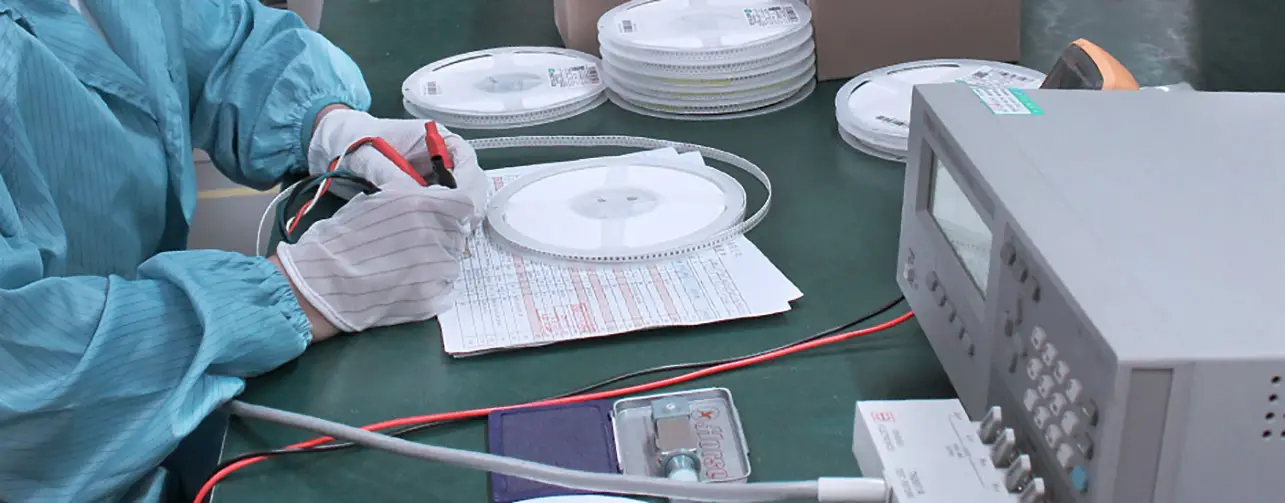

We have a complete supply chain management system, conduct strict audits and certifications for all suppliers, and accept samples and small batch specifications to ensure the qualifications of suppliers. In addition, we are equipped with a powerful IQC incoming material inspection mechanism, conduct AQL sampling standard inspection on all core components, and are equipped with professional inspection laboratories and equipment.

Our advantages in purchasing electronic components?

1. Reliable procurement channels

Shenzhen Kingford Technology Co., Ltd.cooperates with many domestic and foreign electronic component manufacturers and brand authorized agents to fully meet customers' procurement needs for materials in short supply, large and small batches, and sample applications.

2. Checked by the professional quality department

Our professional procurement team strictly screens and classifies suppliers, and only chooses distributors, channel dealers, and agents with high reputation and has been accepted by customers for cooperation. Most of the suppliers are authorized agents of the original brand, guaranteed Product quality of electronic components. We will also order products from designated suppliers in strict accordance with customer requirements, and retain most of the original packaging and labels. If customers need it, we can provide relevant transaction documents with spot suppliers.

There will be a special IQC for quality confirmation and inspection of the purchased raw materials, components or products, that is, when the supplier sends the raw materials or components, the products will be inspected by sampling and full inspection, and finally judge whether the batch of products is Receive or return. We are also equipped with professional electronic component testing equipment, and conduct acceptance inspection in strict accordance with relevant technical document standards and material operation instructions to ensure the quality of materials entering the production line.

3. Warehouse management

Both customer-supplied and electronic components purchased by us are stored in a clean, ventilated, non-corrosive gas warehouse. The temperature of the warehouse is controlled at 23~26°C, and the relative humidity is also controlled at: 45%~75%. Vacuum packaging is carried out for PCB light boards, ICs, etc., to avoid direct exposure of copper foil and pins to oxidation in the air. For electronic components with anti-static requirements (such as: MOS field effect transistors, gallium arsenide field effect transistors, CMOS circuits, ICs, BGAs, etc.), we will store them in anti-static bags, anti-static drying boxes, and anti-static turnover boxes etc. Materials for special requirements are stored according to storage requirements, such as: solder paste, solder paste, glue. The warehouse has a strict material control system and ERP system, in accordance with the principle of first-in first-out, to prevent materials from being expired.

4. Advantages of choosing Kingford

Years of experience: The professional procurement team has more than 6 years of domestic electronic component procurement experience, and has served hundreds of industry customers across the country;

Many channels: not only cooperate with domestic and foreign distributors with high credit rating and real inventory data, but also cooperate with online platforms, offline original factories or agents;

Technical support: Our professional electronic engineers will match more alternative or different brand products according to the BOM provided by customers, optimize the availability of procurement, discover new applicable materials and discontinued materials in time, reduce customer procurement risks, and shorten product delivery time. delivery date;

Cost reduction: flexible procurement can be carried out according to the order quantity specified by the customer: the best price can be obtained by comparing the price range positioning and packaging volume. In addition, we will gather the electronic components that all customers need together for unified procurement , in order to achieve the purpose of saving time, operation and cost of the platform.

More comparisons: It can list the information of all available suppliers for comparison and purchase, including price, delivery date, inventory, etc.

Kingford has long-term cooperative suppliers, which can realize global omni-channel mass procurement of components, real cost performance, real genuine guarantee, and reduce costs and improve efficiency for you. Cooperate with internationally renowned component suppliers and formal channel providers to support the availability of all electronic materials, and establish a strict inspection and testing system to do a good job in risk control such as processing quality and loss, so as to reduce losses for you.