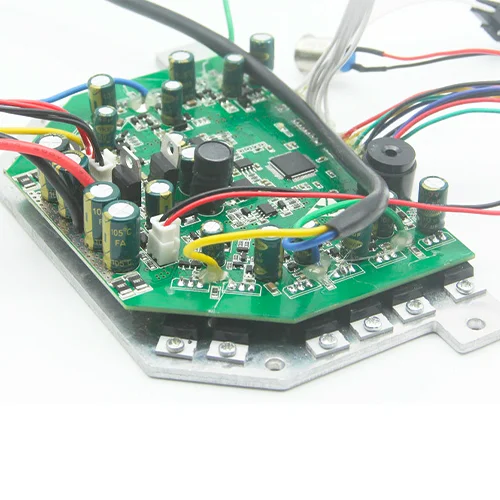

dip plug-in processing manufacturers

Name: dip plug-in processing manufacturers

PCB Type: Rigid Circuit Board

Dielectric: FR-4Material: Fiberglass Epoxy

Application: Consumer Electronics

Flame Retardant Properties: V0

Mechanical Rigid: Rigid

Processing Technology: Electrolytic Foil

Base Material: Copper

Insulation Materials: Organic Resin

Quality Grade: Ipc Class 2, Ipc Class 3

Brand Of Laminate: Kingboard, Iteq, Shengyi, Nanya, Isola, Rogers

PCB Layers: 1~30 Layer

Board Thickness: 0.1~8.0mmBoard Thickness

Tolerance: ±0.1mm / ±10%

Surface Finishes: OSP, HASL, HASL Lf, Immersion Gold, Etc.

Solder Mask Colors: Green, Red, White, Black, Blue, Yellow, Orange

Silkscreen Colors: Black, White, Yellow, Etc.

Electrical Testing: Fixture / Flying ProbeOther

Testing: Aoi, X-ray(Au&Ni), Controlled Impedance Test

What is DIP means in the PCB Assembly industry?

In microelectronics, DIP is short for the dual in-line package, sometimes called a DIL package, which is an electronic device package with a rectangular housing and two parallel rows of electrical connecting pins. The pins are all parallel, point downward, and extend past the bottom plane of the package at least enough to be through-hole mounted to a printed circuit board (PCB), i.e. to pass through holes on the PCB and be soldered on the other side. DIP is also sometimes considered to stand for the dual in-line pin, in which case the phrase “DIP package” is non-redundant.

DIP refers to the device packaged in the form of a plug-in, and the number of pins generally does not exceed 100. Often referred to as “dip welding” or “dip post welding”, refers to the soldering of dip packaged devices after SMT.

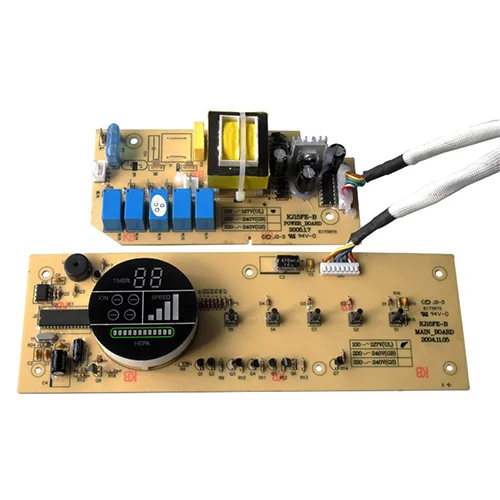

Is DIP the same as SMT?

Not exactly, SMT is the abbreviation of surface mount technology, which is the most popular technology and process in the electronic assembly industry. It is a kind of circuit assembly technology that which the surface assembly components are installed on the surface of the circuit board or other substrates, and are welded and assembled by reflow soldering or immersion soldering.

What is the difference between SMT and DIP?

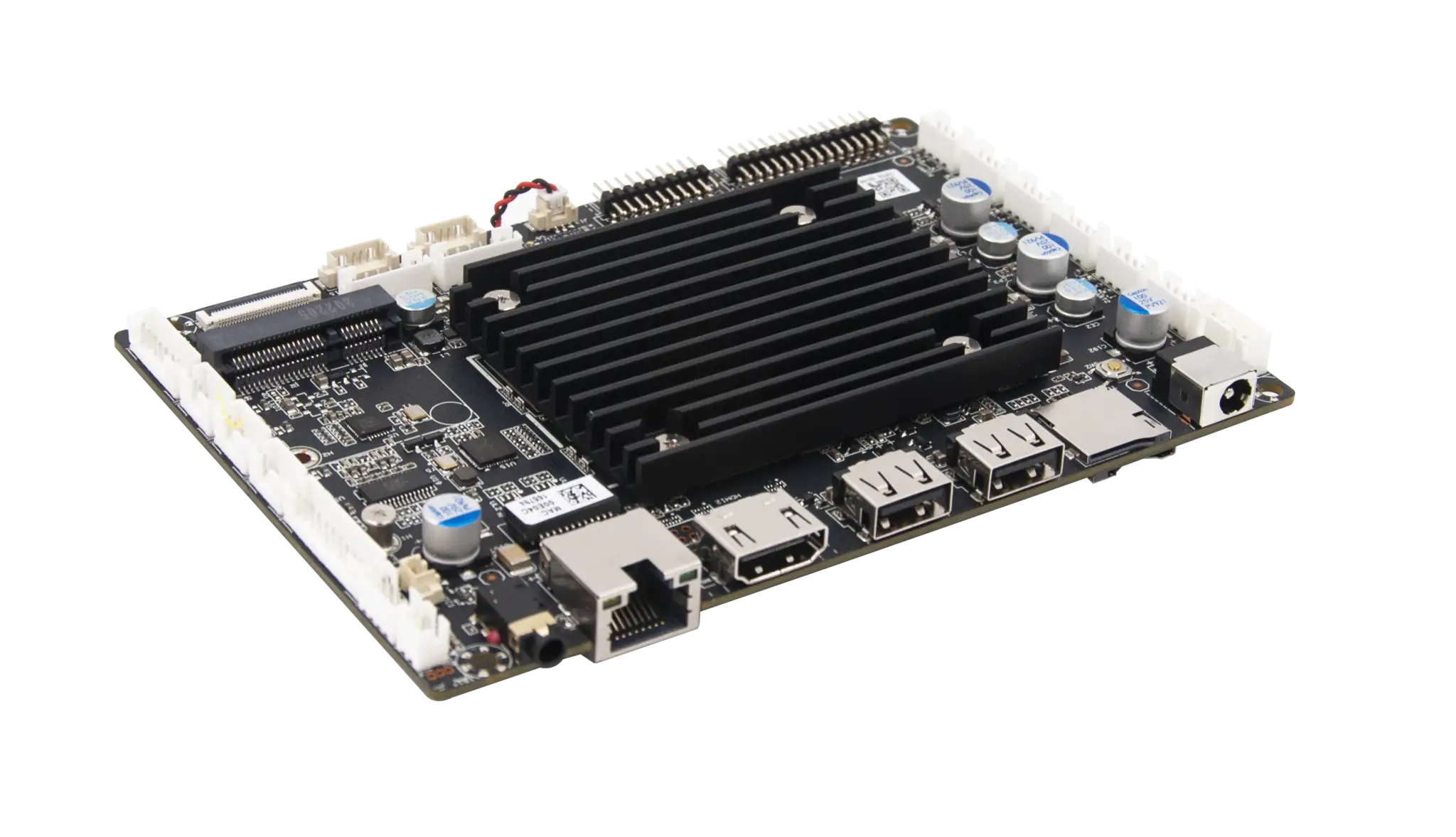

PCB Assembly requires knowledge beyond just PCB components and assembly; it also requires expertise in printed circuit board design, layout, PCB fabrication, and applications of the final product. Auspi is a one-stop solution for all circuit board production services – fabrication, testing/inspections, and assembly. Our clients hire us to be their full or partial turn-key provider from manufacturing to assembly and testing. Through our strong network of well-proven partners, we can provide the most advanced and nearly limitless capabilities for your prototype or production PCB run.

Name: dip plug-in processing manufacturers

PCB Type: Rigid Circuit Board

Dielectric: FR-4Material: Fiberglass Epoxy

Application: Consumer Electronics

Flame Retardant Properties: V0

Mechanical Rigid: Rigid

Processing Technology: Electrolytic Foil

Base Material: Copper

Insulation Materials: Organic Resin

Quality Grade: Ipc Class 2, Ipc Class 3

Brand Of Laminate: Kingboard, Iteq, Shengyi, Nanya, Isola, Rogers

PCB Layers: 1~30 Layer

Board Thickness: 0.1~8.0mmBoard Thickness

Tolerance: ±0.1mm / ±10%

Surface Finishes: OSP, HASL, HASL Lf, Immersion Gold, Etc.

Solder Mask Colors: Green, Red, White, Black, Blue, Yellow, Orange

Silkscreen Colors: Black, White, Yellow, Etc.

Electrical Testing: Fixture / Flying ProbeOther

Testing: Aoi, X-ray(Au&Ni), Controlled Impedance Test