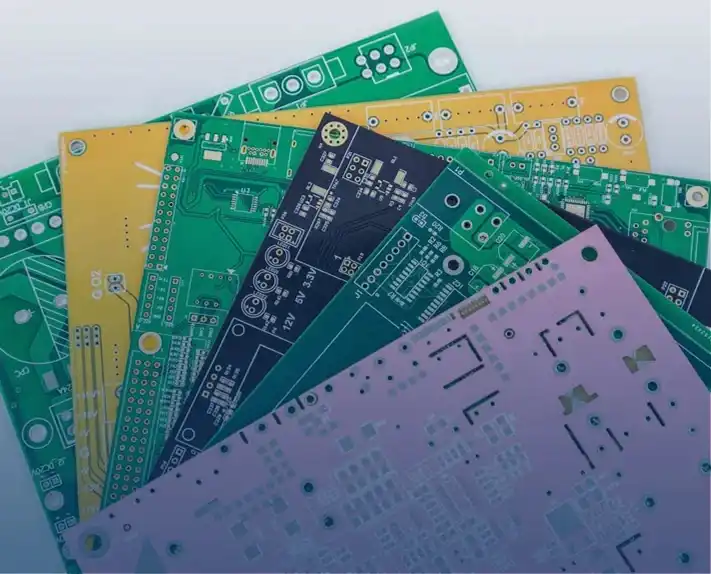

Providing Electronic Design, DfMA Service, PCB Manufacturing,

Component Procurement,PCB Assembly(SMT+DIP), Finished Product Assembly Testing

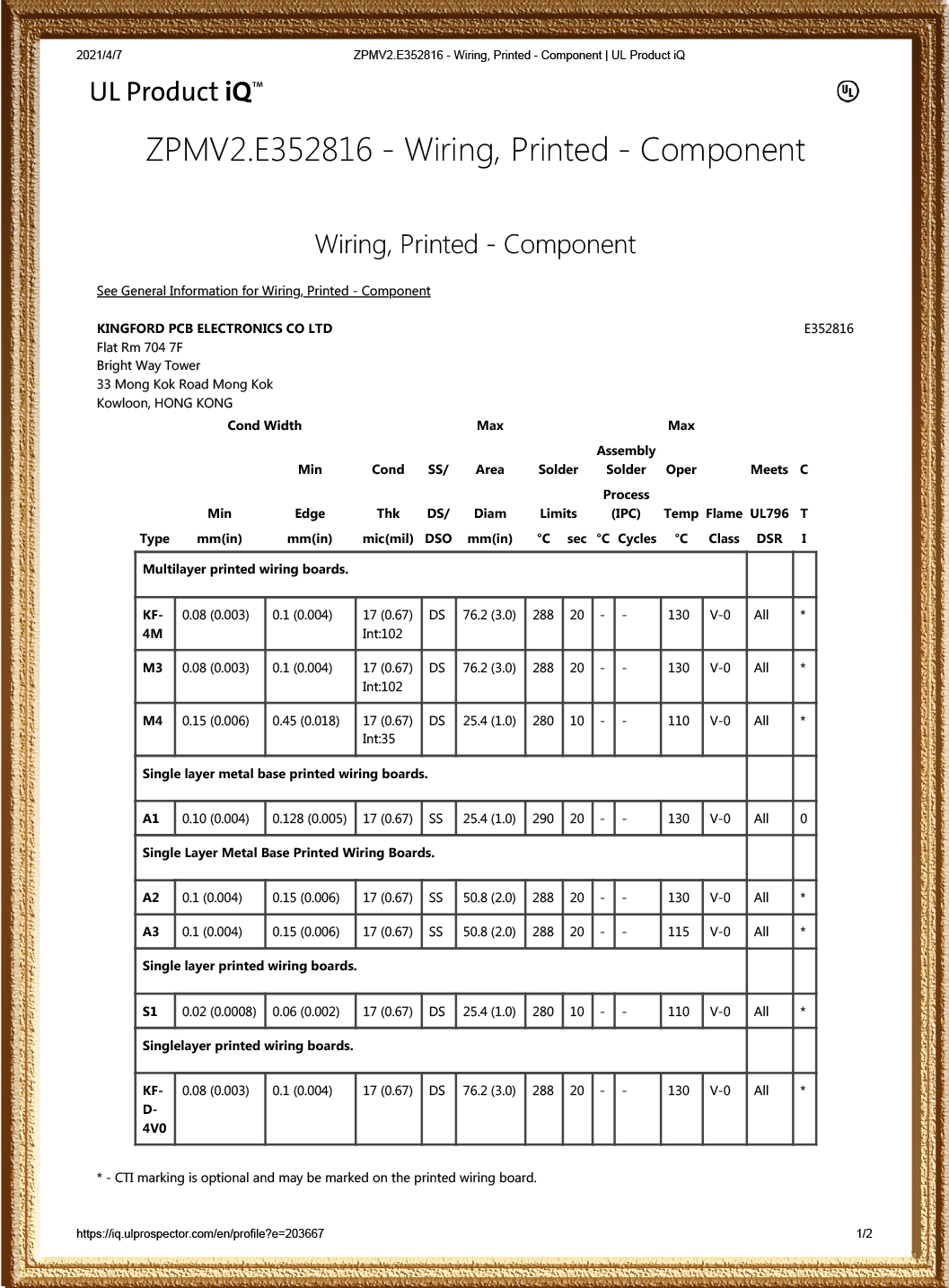

Shenzhen Kingford Technology Co., Ltd. founded in 2012, is a one-stop PCBA solution service provider who integrates PCB Layout, PCB manufacturing, PCBA solution and product design, component procurement, SMT, DIP, finished product assembly and testing, having over 10 years of experience in serving many domestic and foreign brand customers in a wide range of fields such as Medical, Automotive, Industrial Automation, Artificial Intelligence, Smart Home, Security, Power and Communications, etc..

Kingford is committed to meeting the customer needs of "multi-variety, small and medium batches, quick turn delivery, and high quality", and has authoritative certifications of IATF16949, ISO13485, ISO9001 (Quality management system)and ISO14001 (environmental management system. Its KFPCBA Platform achieves the fastest 23-hour delivery of SMT without queuing.

- 7/24 sales and technical supports

- Flexible payment options

- No minimum order requirement

- 10 years overseas export experience

- 2 hours quick response

- Competitive priceing

Plant area

Total number of employees

Global services

Engineers

-

Automatic loading machine

-

PCB cleaning machine

-

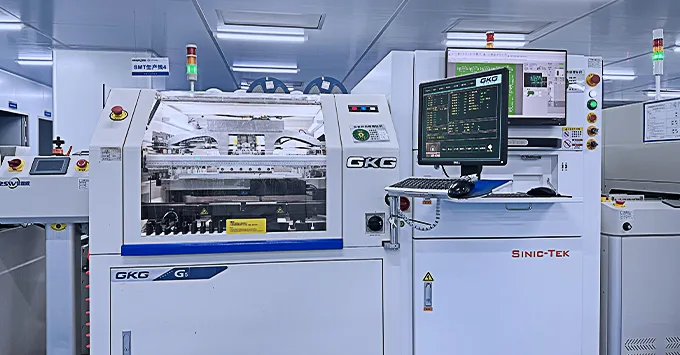

G9+Automatic solder paste printing machine

-

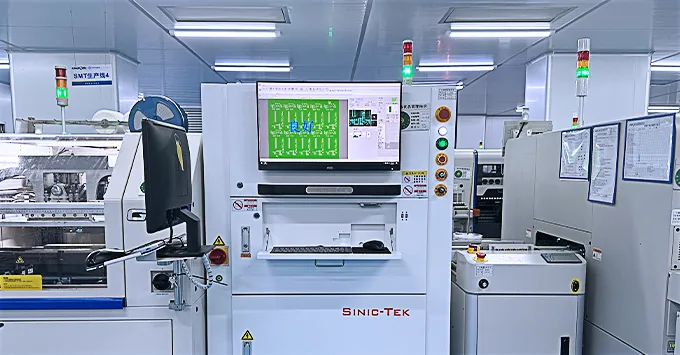

3D-SPI Automatic solder paste testing machine

-

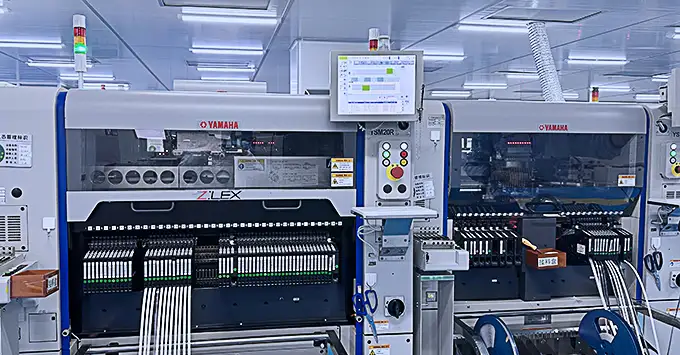

Yamaha YSM20R chip mounter

-

Yamaha YS24 chip mounter

-

Yamaha YSM10 chip mounter

-

Ten temperature-controlled zone nitrogen reflux furnace

-

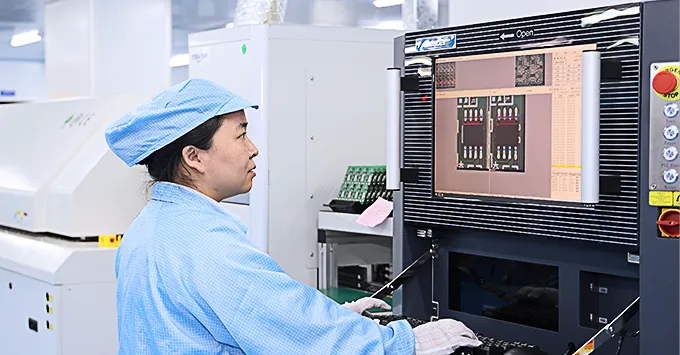

AOI online testing equipment

-

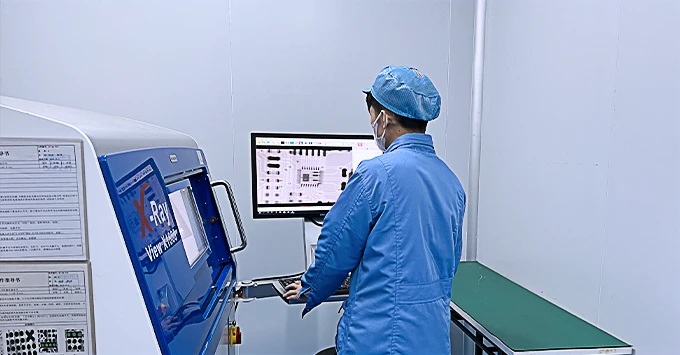

X-RAY

| Automatic loading machine | PCB cleaning machine | G9+Automatic solder paste printing machine | 3D-SPI Automatic solder paste testing machine | Yamaha YSM20R chip mounter | Yamaha YS24 chip mounter | Yamaha YSM10 chip mounter | Ten temperature-controlled zone nitrogen reflux furnace | AOI | X-RAY |

|---|---|---|---|---|---|---|---|---|---|

| Put the unmounted PCB board in the SMT board machine and automatically send the board to the suction board machine | It is specially used for the cleaning of tin beads, flux traces and scratches. It will not generate static electricity and will not damage the PCB board. |

Fully automatic, high-precision solder paste printing; Printing accuracy: ±0.018mm Repeatability: ±0.01mm PCB printing printing circumference: 50X50MM~610x510mm |

Can detect missing printing, less tin, more tin, continuous tin, offset, poor shape, board surface pollution; support rapid detection of 03015, 01005, 0201 solder paste; Detection accuracy: 1µm, Height: 0.37µm PCB size range: 50×50mm(Min)~630×590mm(Max) |

Multifunctional mounter, can mount 01005, 0.35mm BGA Maximum mounting: L50×W50mm~L810×W490mm Position: 140 Speed: 95,000CPH (0.027sec/CHIP) Accuracy: CHIP±0.035mm(±0.025mm) Cpk≧1.0 (3σ) |

High-speed module machine, high precision, the smallest can mount 03015, 01005 and other precision devices; Maximum mounting: L50×W50mm~L700×W460mm Position: 120 Speed: 72,000CPH (0.05sec/CHIP) Accuracy: ±0.05mm(μ+3σ), ±0.03mm(3σ) |

Multifunctional mounter, can mount 01005, 0.35mm BGA Maximum mounting: L50×W50mm~L510×W460mm Position: 48 Speed: 46000CPH (0.078sec/CHIP) Accuracy: ±0.035mm (±0.025mm) Cpk≧1.0 (3σ) |

Lead-free, 10 temperature zones, smooth temperature rise, reliable quality, suitable for super large and super thick PCB welding Temperature control accuracy: within ±1°C Maximum weldable size width: 600mm |

Detection speed:<230ms/FOV PCB size range: 50×50mm(Min)~510×300mm(Max) |

Minimum focus size 0.25um Suitable for open circuit and short circuit detection of BGA, QFN and other devices |

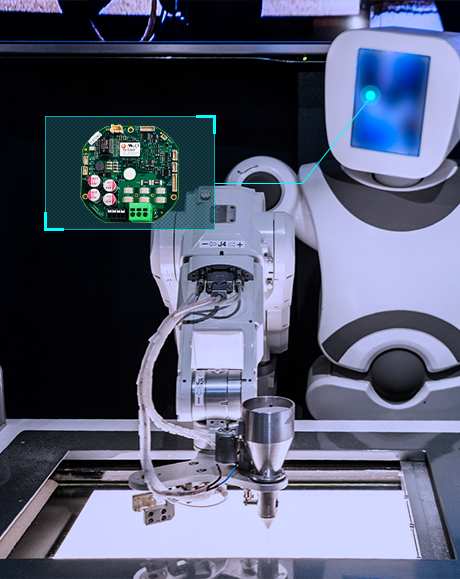

Kingford PCB's factory showcase is a testament to embracing Industry 4.0 digital transformation, in-line with Kingford PCB's ambitions of modernizing the electronics manufacturing industry. By implementing advanced automation and an independently developed MES system, Kingford PCB can maintain consistently high-reliability PCBs at exceptional speeds without compromising cost.

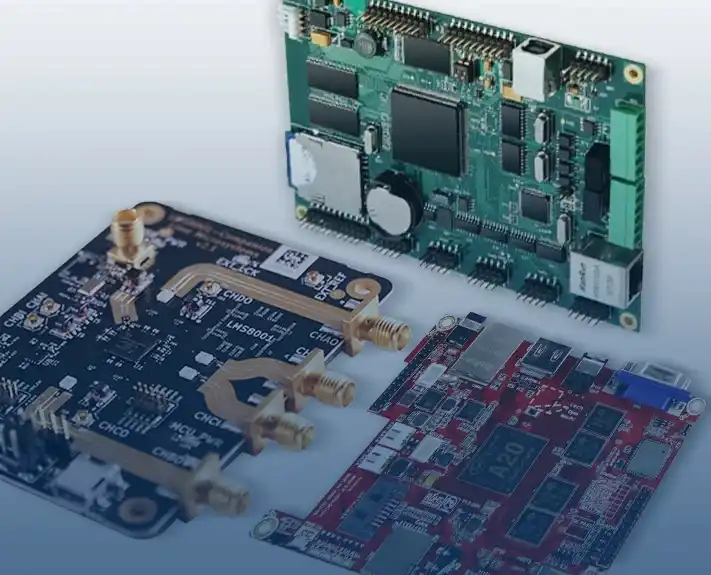

Because we have advanced modern equipment, strict quality control, high-precision assembly,strong R&D team, first-class technical center, and perfect customer resource allocation. Our PCBA factory provides customers with OEM and ODM one-stop professional PCBA Services through continuous innovation.We have established a 100% comprehensive inspection and control system from source to final, and we are a reliable PCB Manufacturing Supplier for you.

We can sign NDA and make sure your personal information only used for orders

No MOQ requested. You may order as 1~10pcs from us. We do not force you to buy what you do not need indeed to save your expenses.

24 Hours customer service, Kitted and Turn-Key options available .

From prototypes to full production runs.

7 automated lines to handle SMT, through-hole, high-mix technology.

Free samples provided, Reliable components sourcing channel.

99% On-Time Delivery, time is money we guarantee ensures you get what you need, when you need it.

Fully Compliant with IPC 610-D Standards, Testing and quality assurance

PCB Fabrication, parts sourcing and PCB assembly.

To accurately calculate printed circuit board manufacturing and assembly costs, please fill out your order form in any convenient way:

- Manufacturing and assembly orders for printed circuit boards. Send us your completed request via email. And upload Gerber files, BOM files, etc. Email sales@kingfordpcb.com

- Fill in detailed requirements for printed circuit board production.

- Fill in the detailed requirements for PCB assembly.

We will send it to your email within 24 hours. Address for commercial quotation indicating cost and production time.

If you need information urgently, please contact us by phone +86-139-2340-1642

Technical parameters for printed circuit board manufacturing can be found in the "Capabilities" section of our website. You can learn more about our assembly production Capabilities in the Capabilities section.

Yes, KINGFORD provides one-stop services from PCB design, PCB proofing, PCBA processing (including SMT and DIP), PCBA testing, and PCBA product assembly and delivery packaging. We have 14 SMT lines,SMT capacity reaches 50 million chips/day,assembly capacity up to 6 million sets/month,6 courier stations, 75000 square meters of dipping lines and 4 product assembly workshops, which will save you time and cost.our PCBA service scope covers all over the world.

With the rapid development of the 5G era, the demand for PCBA in automotive electronics, industrial control, medical equipment and other fields will increase. In addition to 5G mobile phones, smart furniture equipment, smart robots, consumer electronics, medical equipment and other fields will realize intelligent management in the future Internet.

We will contact you at Mon.-Sat.08:00-20:00 (GMT+8)

+86-13923401642