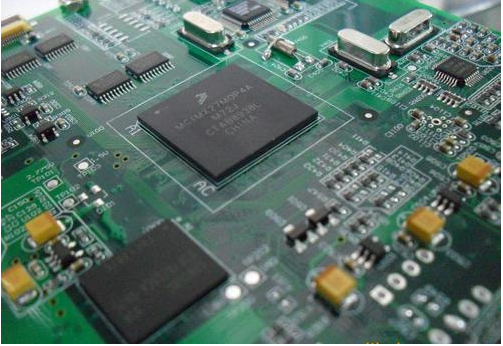

Nickel plating thickness control The gold plating layer of PCB is generally very thin, which reflects that many problems on the gold plating surface are caused by poor nickel plating performance. Generally, the thin nickel plating layer will cause the product appearance to be white and black. So this is a PCB factory project

1. Thickness control of electroplated nickel layer

The gold plating layer on PCB is generally very thin, which reflects that many problems on the gold plating surface are caused by the poor performance of nickel plating. Generally, the thin nickel plating layer will cause the product appearance to be white and black. Therefore, this is the first item to be checked by PCB engineers in the factory. Generally, the thickness of nickel layer should be about 5UM.

2. Liquid medicine condition of nickel plating cylinder

If the nickel cylinder liquid medicine is not well maintained for a long time and carbon treatment is not carried out in time, then the nickel layer of PCB electroplated will be easy to produce lamellar crystals, and the hardness and brittleness of the coating will increase. A serious problem of blackened coating will occur, which is easy to ignore the control focus of many people, and is often an important reason for the problem. Therefore, please carefully check the liquid medicine condition of the production line of your PCB factory, compare and analyze it, and conduct thorough carbon treatment in time to restore the activity of the liquid medicine and clean the electroplating solution.

3. Metal cylinder control

Generally, as long as good liquid medicine filtration and replenishment are maintained, the pollution degree and stability of the gold cylinder will be better than that of the nickel cylinder. However, it is necessary to check whether the following aspects are good: (1) Is the gold cylinder supplement added enough and excessive? (2) How about the control of liquid medicine PH value? (3) How about the conductive salt of the circuit board? If there is no problem in the inspection result, use AA machine to analyze the impurity content in the solution. In the end, don't forget to check whether the filter cotton core of the cash tank has not been replaced for a long time. If it is, you have not strictly controlled it.