Electronic engineer explains the pyrolysis of waste PCB

Circuit board manufacturing, circuit board design and PCBA processing manufacturers will explain to you the pyrolysis of waste PCB by electronic engineers

In recent years, the pyrolysis technology of organic wastes has been applied more and more because of its lower pollution emissions and higher energy recovery. Using pyrolysis technology to treat waste printed circuit boards (PCBs) can not only recover the metals in PCB, but also realize the recycling of non-metallic components such as resin and glass fiber, which has certain attraction.

Pyrolysis is a process in which organic matter is heated to a certain temperature under anoxic or anaerobic conditions to decompose into gas, liquid (oil), solid (coke) and be recovered.

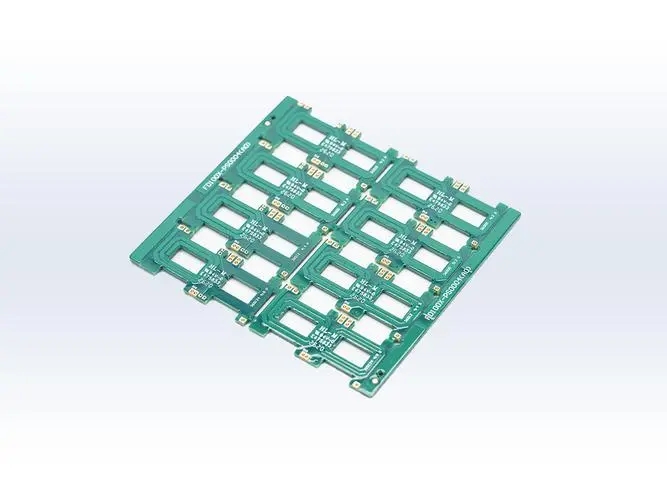

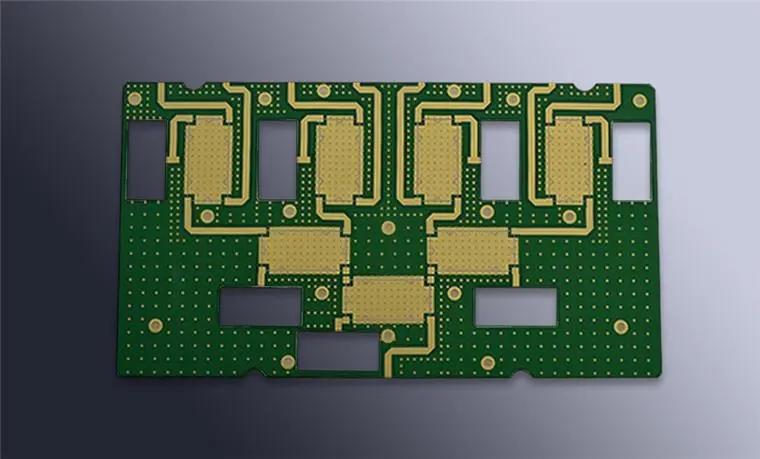

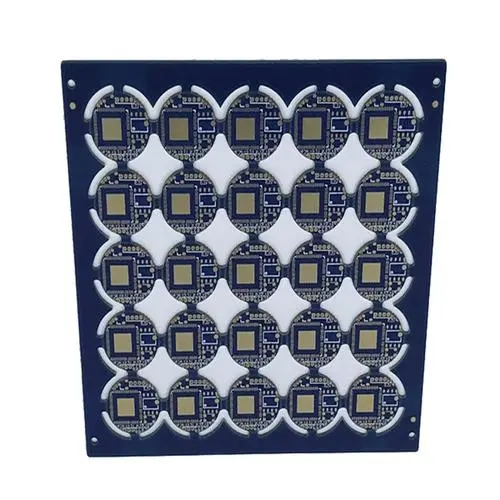

General process flow of PCB pyrolysis

First remove the components on the circuit board, and then crush the board to a certain size and send it to the reactor for pyrolysis. Polymeric materials such as epoxy resin are heated to a certain temperature under the protection of inert gas, and thermal decomposition occurs to generate substances with low relative molecular weight. Condensate the pyrolysis oil and gas from the reactor to obtain non condensable gas and liquid pyrolysis oil. Metal, glass fiber and other components do not change in nature. They are left in the reactor as solid residue and can be separated and recovered by simple physical methods.

The main components of PCB pyrolysis gas are CO2, CO, HBr, low-grade aliphatic hydrocarbons and some aromatic hydrocarbons with low relative molecular weight. Pyrolysis gas has a certain calorific value, which can be used for heat recovery as a heat source in the pyrolysis process.

Pyrolysis oil has complex composition, large boiling point range and high calorific value, which is similar to crude oil. Pyrolysis oil contains many valuable components. If it can be reasonably recycled, the economy of the whole pyrolysis process will be greatly improved.

Recycling of Pyrolysis Oil

It is simple and feasible to use it as fuel when the treatment scale is small and the yield of pyrolysis oil is low. Chien et al. obtained four fractions of light naphtha, heavy naphtha, light oil and gas and heavy oil and gas by distilling pyrolysis oil under normal pressure. The high-temperature distillate with higher calorific value is sold as low-grade fuel, and the low-temperature distillate naphtha and light oil gas after moderate hydrogenation, deoxidation and dehydration can be recycled as the main components of gasoline and diesel.

Extraction of high value-added substances as the main components of chemical raw materials pyrolysis oil phenol and isopropyl phenol are important organic chemical raw materials, which are widely used in plastics, medicine, pesticides, dyes, coatings and other fields. If these substances can be separated and extracted for application, they will have more recycling value than pure fuel. Wang Qing et al. explored the separation process conditions of phenol, isopropyl phenol and water in the pyrolysis oil through the batch distillation test. The content of isopropyl phenol in the separated product was not less than 90, and phenol met the GB3079-1997 standard. Iji et al. pyrolyzed glass fiber reinforced epoxy resin waste in rotary kiln to obtain high-purity glass fiber, and recycled it as epoxy resin polymer filler and insulating material, achieving good results. Circuit board manufacturing, circuit board design and PCBA processing manufacturers will explain to you the pyrolysis of waste PCB by electronic engineers.