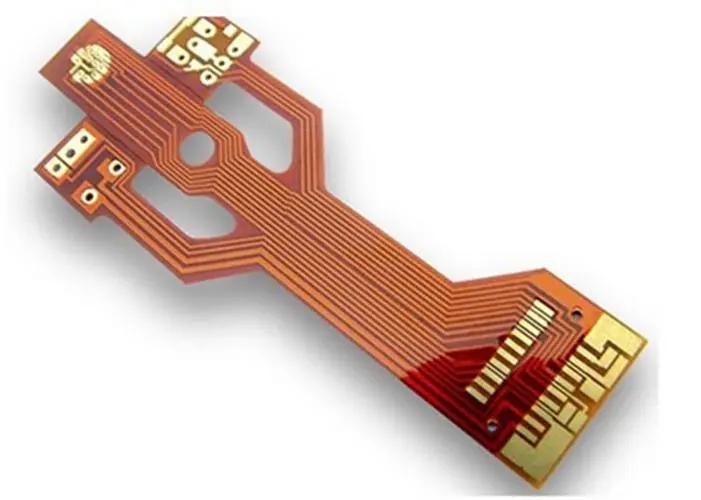

The advantages of high cutting accuracy, low cost and good effect have been fully mature and applied in FPC, membrane switch and backlight industries. Whether it is to precisely semi cut the bonding pad window on the PI coating film, to precisely cut the flexible PCB shape through cutting, or to semi cut the special-shaped thermosetting adhesive film on the back, it can be completed with high speed and quality. This machine is compact, which makes the equipment more concise and refined. It occupies a small area and is easy to choose the installation space. It is the best tool to replace die proofing and laser cutting. It is cut with a knife. Compared with the usual proofing method, it has the following advantages:

Compared with the knife mold: 1. It saves you the expensive mold opening cost when you are testing; 2. It can save your expensive knife sharpening cost; 3. It is convenient to re sample, just change your AutoCAD drawing file, with high efficiency.

Compared with laser: 1. After cutting, the place where the material is cut will not be black; 2. It will not burn when the material is thin; 3. There is no dazzling light when working, which will not harm the workers, and it is quite safe; 4. The price is superior to that of laser. 5. It can cut thin copper foil, conductive cloth, foam and other materials difficult to be processed by laser. It has better quality and higher efficiency than drilling, and can process right angles, corners, etc.

Main application scope: 1. PCB industry: protective film, back glue, pure glue, FPC covering film, electrostatic paper, PET, PVC, conductive cloth, etc; 2. Drawing and proofing of footwear/clothing/carton; 3. Drawing and proofing of sand blasting rubber and sand blasting template in mold factory and stone industry.

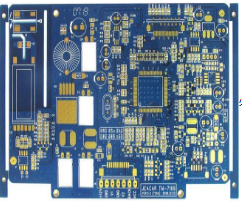

Characteristics of PCB machining

The object of PCB machining is PCB substrate copper clad laminate. Copper clad laminate is made of insulating material and copper foil by hot pressing with adhesive. There are mainly two kinds of reinforcing materials for PCB base material copper clad laminate: glass fiber cloth and

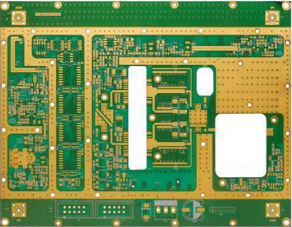

The object of PCB machining is PCB substrate copper clad laminate. Copper clad laminate is made of insulating material and copper foil by hot pressing with adhesive. There are mainly two kinds of reinforcing materials for PCB substrate copper clad laminate: one is glass fiber cloth, and the other is paper based. At present, epoxy glass fiber cloth board is the most widely used in PCB industry.

Whether it is paper substrate or glass fiber cloth board, its PCB processing performance is relatively poor. It can be seen from their structural composition that they are both brittle and obviously layered, with high hardness, high wear on machined tools, and incomplete curing resin is contained in the plate. The heat generated by mechanical friction during processing will soften the incomplete curing resin and make it viscous, increase the friction resistance, break the tool, and produce greasy dirt, affecting the processing quality. In order to improve the machining quality, it is necessary to use cemented carbide tools, and machining with large feed can ensure the machining quality.