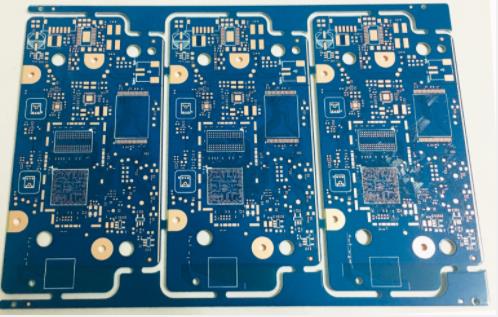

Introduction to Copper Cleaning Technology of PCB Manufacturer

PCB manufacturers, PCB designers and PCBA processors will explain the copper cleaning technology of PCB manufacturers

The purpose of cleaning the copper surface of the circuit board is not only to remove surface contaminants, but also to strengthen the adhesion of the electroplating layer. Especially when a layer of material grows on the copper surface, whether it is organic or metal material, it is safer to conduct surface roughing before growing. If the copper surface is not completely cleaned, it will have the following effects on the metallized layer:

1: Stripping of metal coating and plated object

2: Uneven metal coating and uneven luster affect the appearance

3: Incomplete metallization of the plated object affects the quality

Therefore, only cleaning before metallization can achieve good electroplating effect.

The electroplating equipment and environment of the circuit board are not operated in the clean room, and external pollution such as dust falling from the external environment and the operator's fingerprints is inevitable. However, these external factors are fatal to the electroplating quality, which must be removed to ensure the output quality. There must be hair and powder residues on the board surface after drilling. Therefore, a brush grinding process will be planned for physical cleaning of the circuit board before the glue removal slag process, so that the copper surface can have a clean surface before entering the chemical copper.

After entering the chemical copper manufacturing process, the front steps also belong to the copper surface cleaning operation, which belongs to the chemical cleaning procedures such as degreasing, pickling, micro etching, etc. Only when the copper surface is kept in the cleanest state can the catalyst deposition, catalysis and metallization deposition be carried out.

The surface treatment before chemical copper belongs to chemical cleaning method, which involves degreasing and pickling. Organic solvent, water-soluble degreaser, electrolytic degreasing and other different means will be used for degreasing treatment. For environmental protection, most of the industry currently uses water-soluble and semi water-soluble liquid medicine. The pickling function is to remove the oxides on the metal surface and expose the fresh copper surface to form a good electroplating effect.

In terms of acid cleaners used, inorganic acids such as sulfuric acid and hydrochloric acid are mainly used. Part of the process planning is to avoid the influence of uneven oxidation degree of the incoming circuit board. The micro etching program is planned to conduct slight surface corrosion. It is hoped that the copper surface will be cleaned to a consistent level with a large amount of etching to ensure the freshness of the electroplating surface. Commonly used micro etching systems include sodium persulfate, sulfuric acid and hydrogen peroxide, etc. After micro etching, the metallization step can only be started by acid washing, water washing and other procedures. PCB manufacturers, PCB designers and PCBA processors will introduce the cleaning technology of PCB manufacturers' copper.