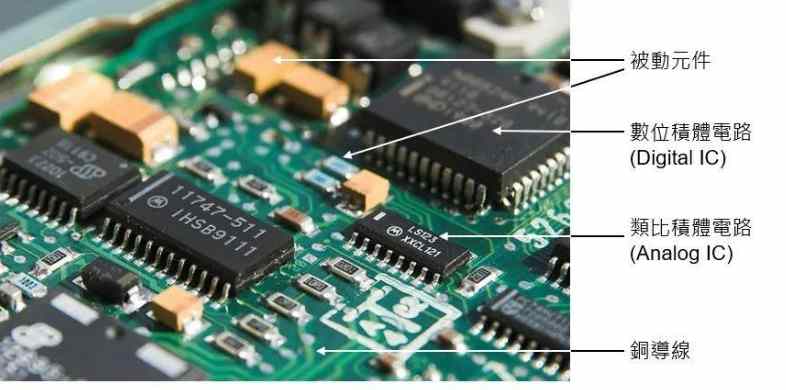

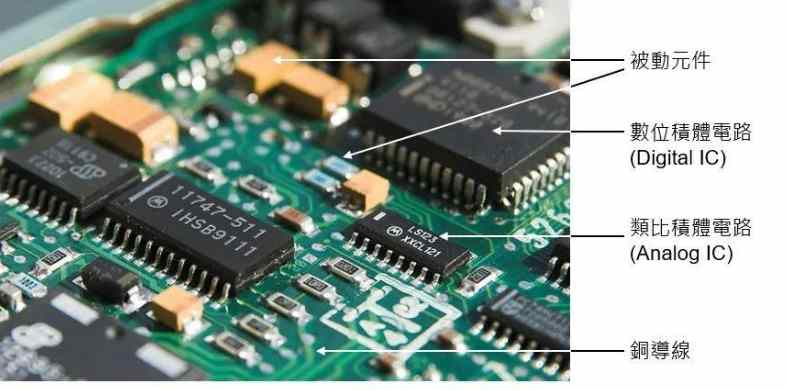

Three anti paint is actually a kind of paint, a special formula used to protect PCBA printed circuit board and related equipment from environmental erosion or protect the production of circuit board and related equipment from environmental erosion. Three anti paint has good high and low temperature resistance; It will form a layer of transparent protective film after curing, with superior insulation, moisture-proof, anti-leakage, shock-proof, dust-proof, anti-corrosion, anti-aging, anti-corona and other properties. Patch processing circuit board in some relatively poor application environment such as chemistry, vibration, high dust, salt spray, humidity and high temperature environment is very easy to appear some corrosion, softening, deformation mold and other problems, and three anti-paint coated on the surface of circuit board and components to form a protective layer, just can ensure the safety of the circuit board and reliability, improve the service life of the product.

Do an experiment: under realistic conditions, such as chemical, vibration, high dust, salt spray, humidity and high temperature environment, the circuit board may produce corrosion, softening, deformation, mildew and other problems, leading to the failure of the circuit board. At this time we use three anti paint coated on the surface of the circuit board, forming a layer of three anti protective film (three anti refers to moisture-proof, salt spray, mildew proof). In the case of chemical substances (such as fuel, coolant, etc.) without the use of three-proof paint circuit board may be corroded, mold growth and short circuit, resulting in circuit failure, the use of three-proof paint can protect the circuit from damage, so as to improve the reliability of the circuit board, increase its safety factor, and ensure its service life. In addition, higher power and closer spacing of the printed board are allowed because the three-proof paint prevents electrical leakage. Thus, the purpose of miniaturization of components can be satisfied. The specific three anti paint is mainly used in where, hundreds of small make up to explain it in detail.

Application of PCBA proofing three anti-paint:

At the beginning of the three - proof paint is only used in the field of high-tech printed circuit boards. As electronic devices are more and more widely used in daily life, so now consumers are more and more concerned about the quality and reliability of products, the use of generic film can enable manufacturers to effectively improve product quality, reduce the expensive warranty period failure costs.

The following hundred thousand to introduce our three anti paint in different industries where to use:

I. Navigation:

Both fresh water and salty sea water can cause harm to electrical wiring of Marine equipment. The use of three anti paint can maximize the protection of the surface and even submerged and underwater equipment. Such as: navigation system, radar control system.

Ii. Civil and Commercial Applications:

Three anti paint can provide protection for electronic circuits in household appliances, so that they can resist: such as: water, moisture, insects, office and home pests. Such as: soybean milk machine, coffee machine, induction cooker, dryer, dishwasher, air conditioning, computer, bathroom electronics, electric vehicles and so on.

Iii. Aerospace:

Due to the particularity of the use environment, the aviation and aerospace environment is strict to the electronic equipment, especially in the condition of rapid compression and decompression, still need to maintain good circuit performance. The pressure stability of three anti - paint is widely used. Such as: satellite system, military control system, flight line control system.

Iv. Automobile Industry:

The automobile industry requires three anti-paint protection circuit from the following situations, such as: gasoline evaporation, salt spray, brake fluid, etc. The application of electronic system in automobile is increasing rapidly, so the use of three-proof paint has become the basic requirement to ensure the long-term reliability of automobile electronic devices. Such as: computer control system, air conditioning, automotive electronics.

Three anti paint is generally in PCBA proofing and plug-in processing and quality inspection and other processing links are finished, in the circuit board coating, the specific protection effect depends on the material and process. In the actual electronic processing, if you just want to improve the insulation level and corrosion resistance of the circuit board surface, you can generally use the process of spraying once on the surface of the non-wash welded PCBA. If it is required to effectively "three prevention" protection, then it must be in strict accordance with the electronic processing plant on the three prevention process requirements for coating