Circuit board maintenance technology is a relatively high-end, more complex technology, about the introduction of circuit board maintenance books, articles are very scarce, want to learn this technology, such as no teacher, only rely on self-study there is a certain degree of difficulty, Guangzhou Keyu trainer believes: "If you want to learn circuit board maintenance technology well, you must lay a solid foundation, be familiar with each electronic component in the circuit board, master the composition structure and working principle of each unit circuit in the circuit board, and combine with practice to master maintenance skills". In general, the following steps can be followed to master circuit board maintenance techniques:

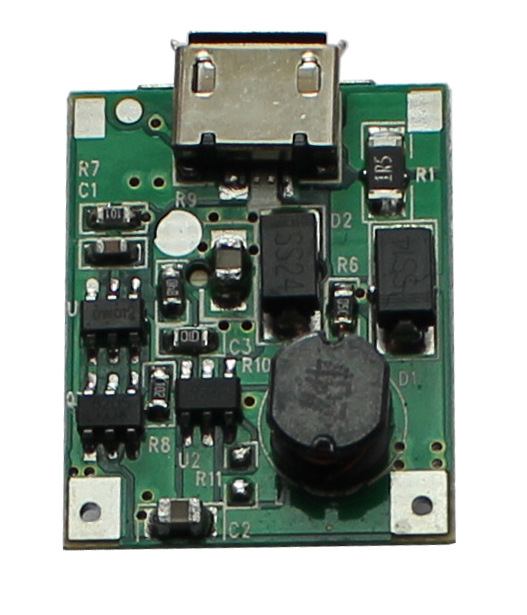

Circuit board repair entry stage. First of all, we should be able to understand each electronic component in the circuit board, familiar with the characteristics of each electronic component, in the circuit diagram and the code on the circuit board, application, good or bad detection, and then master the circuit structure, characteristics, performance parameters, failure mechanism and so on. Finally master the use of common instruments, maintenance tools skills, you can begin to repair the circuit board.

Circuit board maintenance and repair stage. This stage is a stage to improve the skills of circuit board repair, mainly reflected in the repair speed. At this time to improve the circuit board in the composition of various circuit structure, working principle, function, fault diagnosis process, maintenance skills and other knowledge. Master the basic wiring of each electronic component in the circuit board, can draw the schematic diagram of the circuit board according to the real thing, can analyze the context of the signal, the supply of power, etc.

Circuit board maintenance actual combat stage. This stage needs more manual maintenance of some kinds of fault circuit, from the maintenance of the rule of fault summary, find fault skills, learn to write maintenance technical articles, etc., through the maintenance of a large number of fault circuit boards, accumulate rich experience in circuit board maintenance, to become a technical excellent equipment weak current control system hardware maintenance engineer.

First, look after the amount: to repair the circuit board, the first to deal with its visual inspection. Use a magnifying glass if necessary. Mainly look at: 1, whether there is a broken line and short circuit; Especially the printed board on the circuit board connection line whether there is fracture, adhesion phenomenon; 2, the relevant components such as resistance, capacitance, inductance, diode, transistor and so on whether there is disconnect phenomenon; 3. Whether there are problems such as virtual welding, missing welding, reverse insertion and wrong insertion.

Two, the first outside after inside: when using the circuit online maintenance tester for detection, if the situation allows, it is best to have a good circuit board as a reference with the board to be repaired. Then use the double bar VI curve scanning function of the tester to compare the good and bad of the two plates. The starting point of comparison test can be from the board port; Then from the surface to the inside, especially for the capacitor comparative test. This can make up for the multimeter online difficult to measure whether the capacitor leakage.

Three, easy before difficult: in order to improve the test effect, before the online functional test of the circuit board, the board should be repaired to do some technical treatment, in order to minimize the impact of various interference on the test process. Specific measures are as follows: 1. Before the test, short circuit the crystal oscillator. For large-capacity electrolytic capacitors, the next foot should also be welded to make it open. The charge and discharge of large capacity capacitors also cause interference. 2. Test the device by elimination method. In the process of online test or comparison test for the device, all the devices that pass the test (or are more normal) should be directly confirmed and recorded. If the test fails (or is out of tolerance), you can test it again. If you still fail, you can also confirm the test results first. This is continued until the devices on the board have been tested (or compared). Then deal with those that fail the test (or are out of whack). 3. Compare the devices not covered by the test library with ASA-VI curve scanning test. Because ASA-VI intelligent curve scanning technology can be applied to the comparison test of any device. As long as the test clip can hold the device, there is a reference circuit board. Through comparison test, the device also has strong fault detection and judgment ability. This function makes up for the limitation of the device test library in the online functional test, and expands the detection range of the circuit board fault by the test instrument.

Four, static before moving: because at present, only the functional online testing and static characteristic analysis of the devices on the circuit board. Therefore, whether the faulty circuit board is finally completely repaired, it must be installed back to the original equipment for inspection. In order to achieve the correct results of this inspection process, to judge whether the circuit board repair. At this time, it is best to check whether the power supply of the equipment is correctly supplied to the circuit board as required, and whether the interface plug-ins on the circuit board are connected.