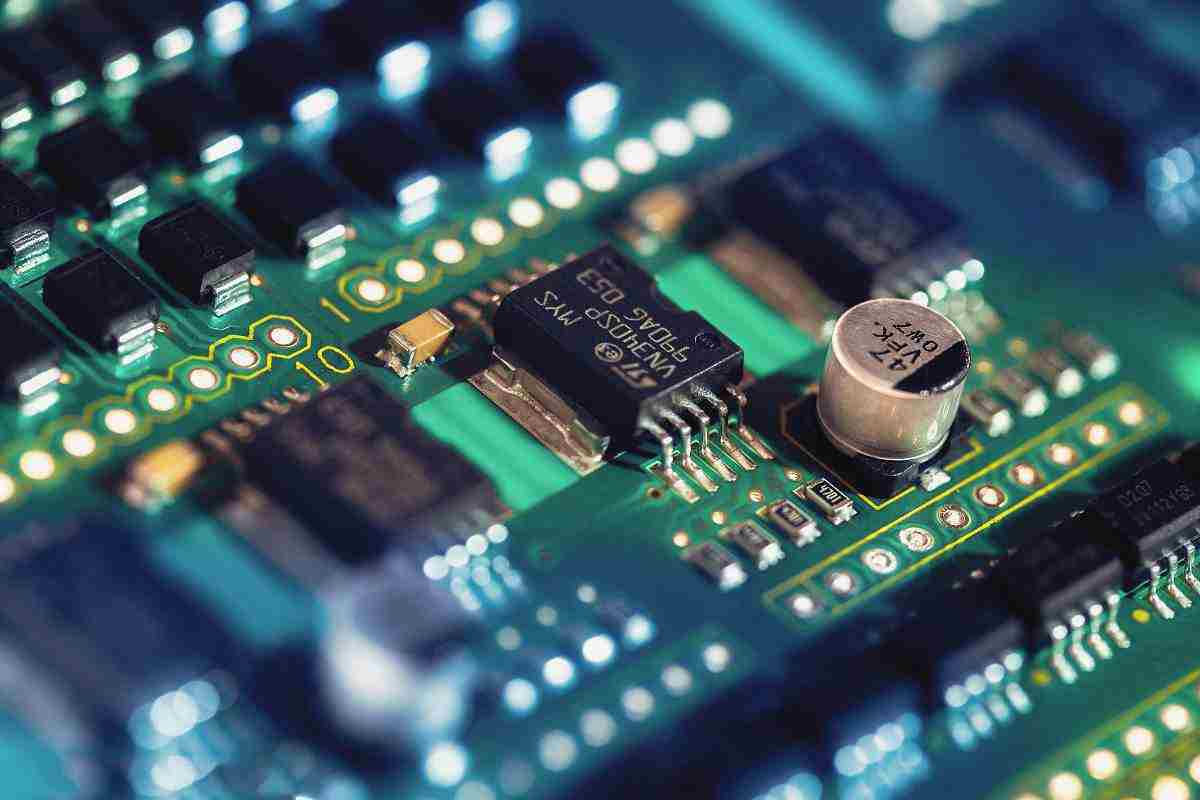

One, Overview

The base material of printed circuit board is usually glass fiber reinforced phenolic resin or epoxy resin, and various components are welded on it. The composition is very complex, including a variety of metals, which has high resource recovery value. PCB contain base metals such as aluminum, copper, iron, nickel, lead, tin and zinc and precious rare metals such as gold, silver, palladium, rhodium, selenium, containing about 25% of the board's mass glass fiber reinforced phenolic resin or epoxy resin.

The metal materials, plastics, glass fiber materials and other materials contained in the waste printed circuit board are all useful and recyclable resources. Among them, the metal material is equivalent to dozens or even hundreds of times of the metal in ordinary minerals, and there is a certain amount of precious metals and rare metals, so it has a high recycling value. Is a big driver of PCB circuit boards.

Waste printed circuit board substrate contains a lot of resin-coated glass fiber, so it has high mechanical properties, can be used as the filler of composite materials, reduce the cost, has a high economic value.

It can be seen that if the waste printed circuit board is not recycled in an appropriate way, it will not only cause great damage to resources, but also the heavy metal halogen polymers contained in the circuit board, such as lead and brominated flame retardants, will cause serious harm to the environment and human body.

Two, waste printed circuit board substrate processing and utilization

How to recycle the waste printed circuit board substrate can be divided into two kinds: physical method recycling and chemical method recycling.

1. Physical recovery

At present, the main metal recovery technology that can be adopted is mostly mechanical crushing, which causes the dissociation of metal in printed board, and then the metal materials and non-metal materials are separated by electrostatic, magnetic, gravity and other sorting methods. The size of non-metallic powder is generally 3 ~ 5μm, and the composition is mainly glass fiber, thermosetting epoxy resin and various additives. These powders can be used as the filler of composite materials for the preparation of composite materials.

According to the composition and properties of non-metallic materials in PCB, non-metallic materials can be used as filler to prepare composite materials. The composite material prepared by powder filling also has the advantages of low density, low water absorption and high hardness, and its mechanical properties are comparable to those of conventional inorganic fillers.

2. Chemical recovery

Chemical recovery, also known as triple recovery, refers to the waste after preliminary crushing, the use of chemical methods to decompose it into small molecules of carbon and oxygen compounds of gas, liquid or coke, at the same time to separate the filler and fiber. The forms of chemical recycling and utilization of discarded circuit board non-metallic materials are:

(1) Pyrolysis recovery method

Pyrolytic method is to break the chemical bonds in the cross-linked thermosetting resin by means of heating, decompose the network of macromolecules into small organic molecules, and the residues are inorganic compounds (mainly glass fibers). At present, there are two main processing processes for non-metallic materials in PCB. One is the direct pyrolysis of the waste circuit board after pretreatment. The non-metallic materials in the circuit board are heated to a certain temperature under the protection of inert gas to generate gas, liquid body (oil) and solid (coke). Solid (coke) contains metal components of waste circuit board and glass fiber residues, and then the physical method is used to separate and recover the metal components. The advantage of direct pyrolysis is to prevent the pulverized nonmetallic powder from being too fine and producing toxic gas during pyrolysis. Another process route is to connect the physical recovery of metals and the pyrolysis of non-metals in series, so as to avoid the impact of metal oxidation on recovery.

(2) solvent recovery

Solvent recovery is a technology that uses organic or inorganic solvents to decompose or hydrolyze the network crosslinked polymer matrix in the waste circuit board into linear organic compounds with low molecular order, so that each component in the composite material is easy to separate and recover.

3. Analysis of recycling technology

For thermosetting printed PCB board substrates, physical recovery does not need to change the chemical state of the substrate resin, simple and convenient operation, low energy consumption and small polluting substances, all waste is used, can alleviate the environmental pressure brought by incineration and landfill. The disadvantage is that the difference of circuit board composition and property and the existence of impurities will cause the degradation of the performance of recycled products or degraded use.

Compared with pyrolysis, solvent recovery method is much milder and does not require too high temperature. However, the solvent recovery method is still in its infancy, and the research objects are mostly thermosetting epoxy resin composites synthesized in the laboratory. There are still many technical difficulties to be overcome in the research process.

Based on the above-mentioned recycling and utilization methods of non-metallic materials in discarded circuit boards, we believe that both pyrolysis recovery and solvent recovery methods are difficult and immature in terms of technical feasibility and practicability, and they are both in the laboratory stage. This method can be used as a new idea for scientific research. Physical pulverization recovery suits our present economic and technical level.

Three. Interface modification of polypropylene composite filled with scrap printed circuit board substrate

In order to obtain high strength composite materials, an effective interfacial bond must be formed between the reinforcing material and the matrix. However, when polypropylene (PP) is used as matrix resin and PCB non-metallic powder to produce composite materials, the poor compatibility between the filler and the polypropylene resin matrix is the main reason that the mechanical properties of the composite materials are greatly decreased.

The interface modification of polypropylene composites filled with scrap printed circuit board substrate is mainly achieved through two aspects: one is to modify the surface of the substrate filler to enhance its adhesion with the substrate polypropylene; On the other hand is the modification of polypropylene on the other hand, so that the filler and resin matrix can fully contact.

Four, conclusion

Considering the above-mentioned recycling methods, physical recycling has great development advantages and is the most suitable resource recycling method for current national conditions. Considering that composite material has become one of the most promising fields in the field of materials, using this material as filler to prepare composite materials has high application value and good market prospect.

At present, there are still many problems in the recycling of non-metallic materials in PCB, resulting in the degraded use of products. How to persuade them to let consumers accept recycled materials is still a matter of time. The recycling disposal of non-metallic materials in PCB is still a serious problem facing the whole country at present, and it still needs time and concrete measures to realize the real recycling and harmless treatment of printed circuit board.