Over the past 20 years, with the continuous development of light, thin, power saving, miniaturization and planarization of electronic information products, surface mount (SMT) technology must be adopted for different uses of electronic products. The tin bead has serious harm to electronic products, so how to reduce the tin bead is one of the key control content of SMT enterprises.

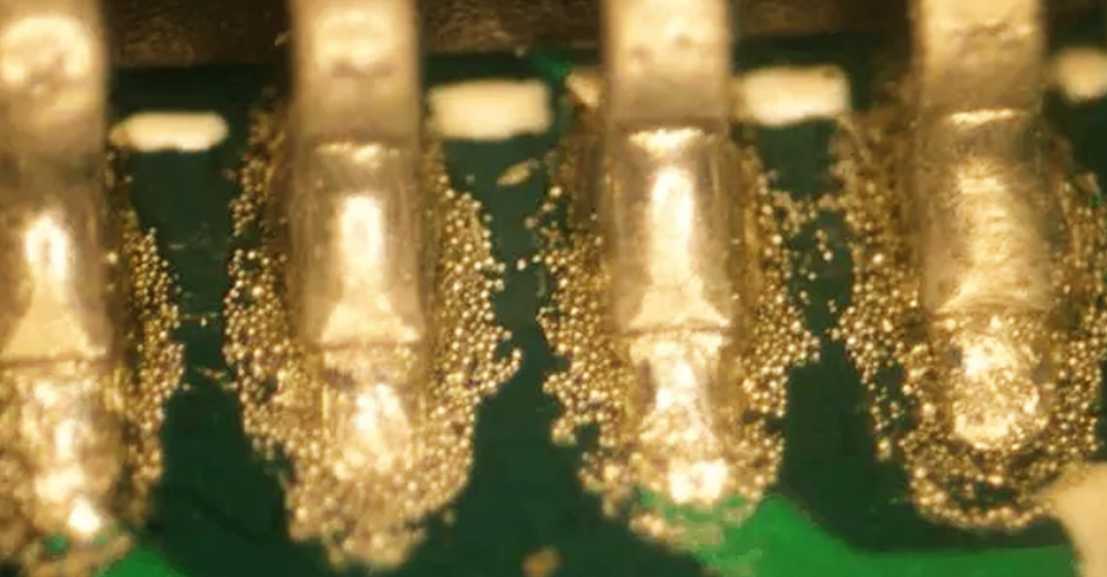

According to relevant cases, during reflow welding in SMT production, it is easy to form tiny spherical solder beads or irregularly shaped solder particles due to the spatter of solder paste metal particles during reflow welding, which is called tin beads. Tin bead is one of the main defects in SMT production. It is about 0.2 ~ 0.4mm in diameter and mainly appears on the side of patch components or between IC pins. It not only affects the appearance of PCB products, but also may cause short circuit in use, which seriously affects the quality and life of electronic products, and may even cause personal injury.

Tin beads are caused by a variety of factors, including raw materials, tin paste, steel mesh, mounting, reflow welding, and environment. Therefore, it is important to study the causes of its occurrence and strive for the most effective control.

The raw material problem leads to the production of tin beads and its control method

1.PCB quality and components

The design of PCB board PAD is unreasonable. If the body of the component presses too much on the PAD and extrudes too much solder paste, it may produce tin beads.

When designing PCB, it is necessary to select suitable component package and suitable PAD.

PCB solder resistance film printing is not good, rough surface, resulting in tin beads during reflux, must be tightened PCB incoming material inspection, welding resistance film seriously bad, must be rejected or scrapped.

The solder pad has moisture or dirt, which leads to the production of tin beads. The moisture or dirt must be carefully removed from the PCB before it is put into production.

In addition, customers often meet the substitution requirements of incoming materials for devices with different package sizes, resulting in mismatch between devices and PAD, which is easy to produce tin beads. Therefore, substitution should be avoided as far as possible.

2. PCB is damp

There is too much water in PCB. When the PCB passes through the reflux furnace after mounting, the water will expand rapidly and produce gas, resulting in tin beads. It is required that PCB must be packed in dry vacuum before putting into SMT production. If there is damp, it needs to be baked in oven for use. For organic bonded film (OSP) plates, baking is not allowed. According to the production cycle, the OSP board is not more than 3 months can be online production, more than 3 months need refueling.

3. Selection of tin paste

Solder paste significantly affects the welding quality. The metal content, oxide content, metal powder size and solder paste activity all affect the formation of solder beads to varying degrees.

Metal content, viscosity. Normally, the volume ratio of metal content in solder paste is about 50%, the mass ratio is about 89% ~ 91%, and the rest is Flux, rheological modifier, viscosity control agent, solvent, etc. If the proportion of flux is too much, the viscosity of the solder paste is reduced. In the preheating zone, the force generated when the flux gasification is too large is easy to produce tin beads. Solder paste viscosity is an important factor affecting printing performance, usually between 0.5 ~ 1.2 KPa·s, the best solder paste viscosity is about 0.8 KPa·s in steel screen printing. When the metal content increases, the viscosity of the solder paste increases, which can more effectively resist the force generated by gasification in the preheating zone. It can also reduce the collapse trend of the solder paste after printing and reduce the tin beads.

Oxide content. The content of oxide in solder paste also affects the welding effect. The higher the oxide content, the greater the resistance in the combination process of metal powder after melting. In the reflow welding stage, the oxide content on the surface of metal powder will increase, which is not conducive to the "wetting" of the pad and the generation of tin beads. Therefore, vacuum operation must be required in the preparation of metal Powder to prevent Powder oxidation.

Particle size and uniformity of metal powders. Metal powder is a very fine spherical particle, and its shape, diameter and uniformity all affect its printing performance. The oxide content in the fine particles is higher, if the proportion of fine particles is large, there will be better printing clarity, but it is easy to produce collapsing edge, so that the tin beads increase; The larger particle proportion is large, so that the increase of tin, the uniformity of the difference is large, will lead to the increase of tin beads.

Solder paste activity. Tin paste activity is not good, dry too fast, if excessive diluent is added, in the preheating zone, the force generated by diluent gasification is too easy to produce tin beads. If you encounter bad activity of tin paste, it is best to stop immediately and replace the activity of good.

Tin beads produced by steel mesh problem and its control method

The steel mesh is too thick, the solder paste printing is thick, easy to produce tin beads after reflow welding.

If the steel mesh is too thick and leads to more tin beads, re-make the steel mesh as soon as possible.

It is easy to produce tin bead when the steel mesh is not treated with tin bead. Whether there is lead or no lead, the Chip parts of the tin steel mesh should be anti-tin bead holes.

Improper opening of steel mesh, too large, offset, will lead to the production of tin beads. PAD size determines the size of the opening of the steel mesh, and the most critical elements of the design of the opening of the steel mesh are size and shape. In order to avoid excessive solder paste printing, the opening size is designed to be less than 10% of the corresponding pad contact area; The opening design of the lead-free steel mesh should be larger than that with lead, so that the solder paste can cover the pad as completely as possible.

Tin beads produced by improper adjustment of press parameter setting and its control method

After printing, the solder paste has the phenomenon of collapsing, and the tin bead may be formed after the reflux furnace. The solder paste has a collapsing edge, which is related to the press scraper pressure, speed and release speed. If there is the phenomenon of solder paste edge collapse, it is necessary to readjust the scraper pressure, speed or stripping speed to reduce the edge collapse and reduce the occurrence of tin beads.

Start printing without proper positioning, printing offset, so that part of the solder paste on the printed circuit board, may form tin beads.

The tin paste printed on the PAD is too thick, and the excess tin paste spills after the component is pressed down, which is easy to form tin beads. Solder paste printing thickness is a major parameter in production, usually equal to the thickness of steel mesh (1+10%±15%), too thick lead to the collapse of the edge is easy to form tin beads.

The printing thickness is determined by the thickness of the steel mesh, and has a certain relationship with the setting of the machine and the characteristics of the solder paste. The micro adjustment of printing thickness is usually achieved by adjusting scraper pressure and printing speed.

Tin beads are produced due to mounting pressure problem and its control method

If the installation pressure of the patch is set too high, when the component presses on the solder paste, there may be a part of the solder paste squeezed under the component. During reflow welding, this part of the solder paste is easy to melt and form tin beads, so the appropriate installation pressure should be selected.

Tin beads produced by furnace temperature problem and its control method

The reflow curve can be divided into four stages: preheating, holding, reflow and cooling. In the preheating stage, the temperature rises to 120 ~ 150 degrees, which can remove the volatile solvent in the solder paste and reduce the thermal vibration of the element. At the same time, gasification will occur inside the solder paste. If the bonding force between the metal powder in the solder paste is less than the force generated by gasification, a small amount of solder paste will overflow from the PAD, and some will hide under the flake resistance and volume parts, and form tin beads after reflux.

It can be seen that the higher the preheating temperature is and the higher the temperature in the preheating zone is, the more splashing the gasification phenomenon will be, the easier it is to form tin beads. Therefore, adjust the reflux furnace temperature, reduce the conveyor belt speed, take a more moderate preheating temperature and preheating speed to control the tin beads.

Process control problems lead to the generation of tin beads and its control methods

Precautions for the use of tin paste mainly include the following aspects: under the specified storage conditions, the storage period of tin paste is generally 3 ~ 6 months;

The solder paste should be used in accordance with the principle of "first in first out", and should be stored in a sealed form in a constant temperature refrigerator, at a temperature of 2℃ ~ 10℃; Before use, take it out of the refrigerator and keep it sealed at room temperature for at least 4H. When the tin paste reaches room temperature, open the bottle cap. After taking out part of the tin paste, squeeze all the air between the inside lid and the tin paste, and close the outer lid immediately. If the bottle is opened at low temperature, easy to absorb water vapor, and then flow welding is easy to produce tin beads; After opening, it should be stirred evenly according to the requirements to reduce the viscosity of the solder paste. After opening the lid, it should be used in one time within the same day in principle; When the solder paste is placed on the steel net for more than 30 minutes and not used, the stirring function of the printing press should be used after stirring. If the interval is longer (more than 1H), the solder paste should be put back into the jar and the lid should be tightly closed. When the solder paste is collected from the steel mesh, another empty can should be replaced to prevent contamination of the fresh solder paste. The solder paste scraped back from the steel mesh should also be sealed and refrigerated.

Process management also has its corresponding requirements: the optimal temperature of printing is 25℃±3℃, the relative humidity is 45% ~ 65%, the temperature and humidity is too high, the solder paste is easy to absorb water vapor, and the reflux is easy to produce tin beads; After printing failure, it is best to thoroughly clean PCB with ultrasonic cleaning equipment, dry it and then bake it in oven according to specifications, in order to prevent tin beads in reuse; Clean the steel mesh is not timely, or wipe is not thorough, resulting in residual solder paste on the back of the steel mesh, pollution PCB board surface, produce tin beads. Must operate in strict accordance with the steel mesh cleaning specifications, and determine the cleaning and inspection of special personnel; After printing the solder paste, the PCB should be affixed in the shortest possible time to prevent the volatilization of solvents such as flux and the easy production of tin beads.

In SMT production, there are many factors to produce tin beads, so it is far from enough to only pay attention to one aspect or adjust one parameter. We need to carefully control all details in the preparation stage before production and in the production process, and study how to control the factors affecting tin beads, so as to achieve the best welding effect and meet the high quality requirements of electronic connection technology.