When using electric soldering iron for welding, PCBA sometimes produces tin beads. If there are too many tin beads or customers with strict requirements, it is easy to be judged as defective products. In order to improve the quality of PCBA welding, it is necessary to find out the causes of tin beads, and then improve.

The reasons for the production of tin beads in electric iron are mainly as follows

1, the electric iron temperature is too high, the tin wire temperature is too fast, resulting in boiling of the flux solvent in the tin wire composition, causing frying tin, thus producing tin beads.

2, the quality of tin wire is not good, tin wire will produce tin bead splash, well-known brands, good quality tin wire splash degree is generally smaller, choose good tin wire is also very important.

3, tin wire or welding end damp, also easy to produce tin beads, need to pay attention to the temperature and humidity of the workshop, reasonable storage.

The technical level of electric soldering iron operators is low, and they do not operate according to the requirements. Tin beads will also occur. To improve the technical level of employees, tin beads of PCBA welding can be reduced.

2. How to prevent common false welding and false welding defects in PCBA welding?

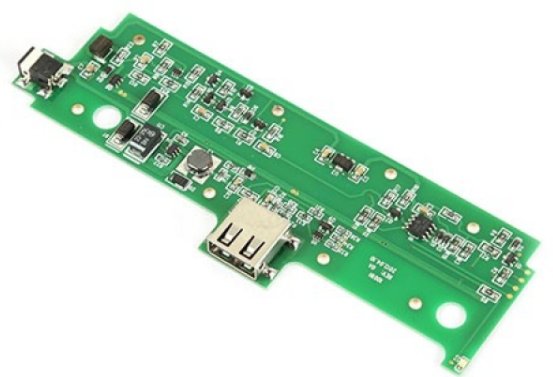

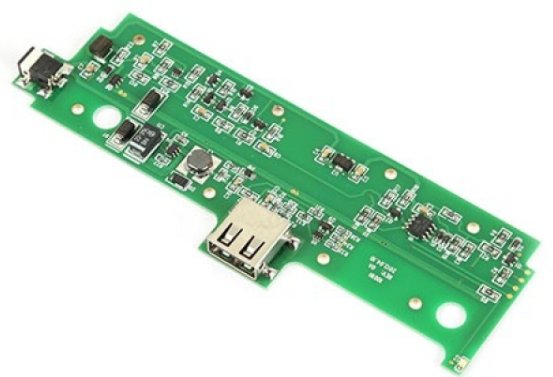

PCBA welding processing mainly refers to the production process of soldering PCB circuit board and components. In the process of welding, it is easy to have poor welding, such as false welding and false welding, which will seriously affect the reliability of products and greatly improve the maintenance cost of products.

The problems of false welding and false welding defects in the welding process of PCBA are caused by many reasons. The main reason is that the solder cannot fully infiltrate the pad and the pin of the component, and the pad of the component and the circuit board cannot be fully welded. In the production process, it can be prevented in the following ways.

1. Moisture-proof storage of components

If components are placed in the air for a long time, they will absorb moisture and oxidize. As a result, components cannot fully remove oxides in the welding process, resulting in defects of virtual welding or fake welding. Therefore, in the welding process, to have moisture components for baking, for oxidation components to replace. Generally, the PCBA processing plant will be equipped with an oven to bake the components with water vapor.

2, choose well-known brand solder paste

In the process of PCBA welding, the defects of false welding and false welding have a great relationship with the quality of solder paste. The composite metal composition of solder paste and the unreasonable configuration of flux are easy to lead to the weak activation ability of flux in the welding process, and the solder paste can not fully infiltrate the pad, resulting in virtual welding and false welding defects. Therefore, you can choose famous brands like Qianzhu, Alpha, Weituo and so on.

3. Adjust printing parameters

The problem of virtual welding and false welding is largely due to the lack of tin. In the printing process, the pressure of scraper should be adjusted, the appropriate steel mesh should be selected, and the steel network port should not be too small to avoid the situation of too little tin.

4, adjust the reflow welding temperature curve

In the reflow welding process, we should control the welding time. If the time is not enough in the preheating zone, the flux can not be fully activated and the surface oxide of the welding can be removed. If the time is too long or too short in the welding zone, it will cause virtual welding and false welding.

5, try to use reflow welding, reduce manual welding

Generally, when the electric iron is used for manual welding, the technical requirements for the welding personnel are relatively high. The temperature of the iron head is too high or too low, or when the welding components are loose, it is easy to cause virtual welding and fake welding. The use of reflow welding can reduce the artificial external factors and improve the quality of welding.

6, avoid the electric iron temperature is too high or low

In the post-welding processing and maintenance of PCBA welding, it is necessary to use electric soldering iron for manual welding. In the use of electric iron, non-standard operation, resulting in the temperature of the iron head is too high or too low, it is easy to cause virtual welding and false welding. Therefore, in welding, to keep the iron head clean, according to the size of different parts and solder joints, device shape to choose different power types of electric iron, the welding temperature is controlled between 300℃ - 360℃.

Virtual welding and false welding caused in the process of PCBA welding are caused by many factors, and the above is just to list some common reasons. Through the above preventive measures, combined with the actual situation, it can effectively reduce the welding defects of virtual welding and false welding.