The processing process of PCBA patch mainly includes solder paste printing, mounting, reflow welding and AOI testing. The process is relatively complex, and non-standard operation in any link will seriously affect the quality of PCBA patch. The quality of PCBA patch can be effectively improved through the key links of steel mesh making, solder paste control, furnace temperature curve setting and AOI detection.

One, steel mesh production

The solder paste is leaked to the solder plate of PCB board through the steel mesh. The quality of the steel mesh has a very important influence on the tin effect of the PCB solder plate. There are a lot of defects such as more tin and less tin and the opening of the steel mesh has a great relationship.

The opening of the BGA steel mesh needs to be adjusted reasonably according to the size of the pin ball and the gap of the BGA chip, between the virtual welding and short circuit

Our products use a lot of BGA package specifications, so we must refer to the chip situation, not according to the general situation (88%-95% of the recommended opening ratio).

During the acceptance of steel mesh, note the following:

1. Check whether the opening mode and size of the steel mesh meet the requirements

2. Check whether the thickness of the steel mesh meets the product requirements

3. Check whether the frame size of the steel mesh is correct

4. Check whether the steel mesh is completely labeled

5. Check whether the flatness of the steel mesh is level

6. Check whether the tension of the steel mesh is OK

7. Check whether the positions and number of openings of the steel mesh are consistent with those in the GERBER file

The intact steel mesh can leak out good solder paste, which lays a good foundation for improving the welding quality of the post sequence.

Two, solder paste control

Solder paste is a welding material for PCBA patch processing, and the quality of solder paste has an important impact on the final welding quality, so it is necessary to strictly control the solder paste.

1, tin paste preservation

(1) The storage temperature of the solder paste is 0~10℃. If it exceeds the storage temperature range, it is necessary to adjust the temperature range of the refrigerator.

(2) The service life of the solder paste is 6 months (unopened).

(3) The solder paste taken out of the refrigerator should not be placed in the sunlight.

2. Use of tin paste

(1) Before opening, the temperature of the solder paste must rise to the ambient temperature (25±2℃), and the return temperature time is about 3-4 hours, and it is forbidden to use other heaters to make its temperature rise instantaneously; The stirring time should be 1-3 minutes, depending on the type of mixer.

(2) Depending on the production speed, the amount of solder paste on the steel net should be supplemented by a small number of times to maintain the quality of solder paste.

(3) The unused solder paste can not be placed together with the unused solder paste, and should be stored in other containers. After opening, it is recommended to use up the solder paste within 24 hours at room temperature.

(4) When using the next day, the newly opened solder paste should be used first, and the unused solder paste and the new solder paste should be mixed in a ratio of 1:2, and a small number of times to add the use.

(5) If the line is changed for more than 1 hour, scrape the solder paste from the steel plate to cover the tin paste can before the line is changed.

(6) After 24 hours of continuous printing of solder paste, due to air dust and other pollution, in order to ensure product quality, please follow the method of "Step (4)".

(7) Please control the indoor temperature with 22-28℃, RH30-60% humidity is the best operating environment.

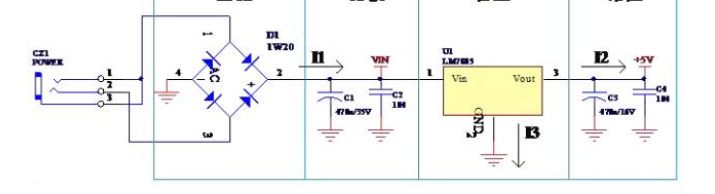

Three, reflow welding furnace temperature curve setting

The setting of reflow welding parameters is the key to affect the welding quality. The temperature curve can provide an accurate theoretical basis for the setting of reflow furnace parameters. Each product will have a corresponding temperature curve, in the reflow welding of new products, it is necessary to use the furnace temperature tester for testing.

Key places affecting furnace temperature:

1. Set the temperature values of each temperature zone

2. Temperature difference of each heating motor

3, the chain and the speed of the net belt

4, the composition of tin paste

5, PCB circuit board thickness and component size and density

6. Number of heating zones and length of reflow welding

7, the effective length of the heating area and the characteristics of cold, etc

Good furnace temperature curve, only set up in line with the product welding parameters, improve the reflow welding quality.

Four, AOI detection

AOI detector is commonly placed in the back of the reflow welding process, AOI can detect a lot of bad defects in the previous process, such as more tin, less tin, polarity direction, monument and so on. Through AOI detection, the printed circuit board with problems can be detected, and the process of avoiding the problem of the board subflow in the later sequence is very important to improve the quality of PCBA patch.

In the process of PCBA patch processing, there are many factors affecting product quality. Through strict control of the above key points, the quality of PCBA patch can be effectively controlled.