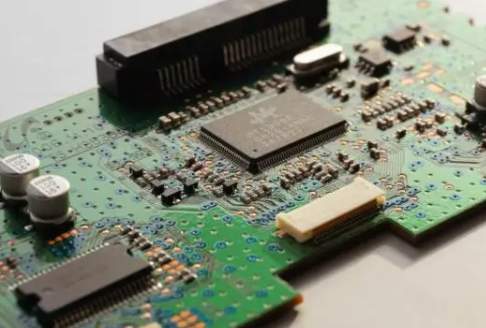

In order to complete the quality inspection, the quality objectives of SMT patch proofing processing with high qualification rate and high reliability need to control the design scheme, components, data, process, equipment, rules and regulations of the printed circuit board. SMT patch proofing quality inspection includes feed inspection, process inspection and surface assembly board inspection. According to defect analysis, the quality inspection process of SMT patch proofing can reduce defect rate and reject rate, reduce rework and maintenance cost, and avoid quality hazards from the source. SMT shall follow reasonable testing methods to avoid defects and hidden dangers before proceeding to the next process.

I. Inspection of incoming SMT materials

SMT patch proofing quality inspection includes feed inspection, process inspection and surface assembly board inspection. Quality problems found in process inspection can be corrected according to the rework situation. The rework cost of unqualified products found in incoming inspection, solder paste printing and pre-welding training is relatively low, which has little impact on the reliability of electronic products. But the rework of unqualified products after welding is completely different. In addition to working time and materials, components and circuit boards can also be damaged because post-weld repairs require soldering from scratch. According to defect analysis, the quality inspection process of SMT patch proofing can reduce defect rate and reject rate, reduce rework and maintenance cost, and avoid quality hazards from the source.

Two, SMT processing and testing

SMT patch proofing and welding inspection is a comprehensive inspection of welding products. Generally, the points to be detected are: whether the spot welding surface is smooth, whether there are holes, holes, etc. Whether spot welding is crescent shape, whether there is more or less tin, whether there are defects such as standing tablets, Bridges, parts moving, missing parts, tin beads, etc. Whether the parts have defects of different levels; Check whether there are defects such as short circuit and conduction during welding, and check the color change of the printed circuit board surface.

In the process of patch processing, to ensure the welding quality of PCB, it is necessary to pay attention to whether the technical parameters of reflow welding are reasonable. If the parameter setting is wrong, the welding quality of PCB cannot be guaranteed. Therefore, under normal conditions, furnace temperature must be tested twice a day, low temperature test once. Only by constantly improving the temperature curve of welding products and setting the temperature curve of welding products, can the quality of processed products be guaranteed.

The quality inspection of professional SMT patch proofing must be very strict. Only strict quality inspection can ensure the quality of SMT processed products. The Pearl River Delta. SMT factories are everywhere. It can even be said that nine out of ten industrial zones have electronics processing plants. If you want to survive and expand in this environment, ensuring product quality is a prerequisite.

kingford PCBA processing advantages

1. Strength guarantee

▪SMT workshop: We have imported SMT machines and several sets of optical inspection equipment, with a daily output of 4 million. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪DIP production line: We have two wave-soldering machines, among which there are more than 10 old employees who have worked for more than three years. The skilled workers can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

▪ High-end equipment can stick precision shaped parts, BGA, QFN, 0201 materials. Can also template patch, loose material hand.

▪ Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated SMT SMT processing services for thousands of electronic enterprises, involving many kinds of automotive equipment and industrial control motherboard. The products are often exported to Europe and the United States, and the quality can be affirmed by new and old customers.

▪ On time delivery, normal 3-5 days after complete materials, small batch can also be expedited on the same day shipment.

4. Strong maintenance ability and perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connection rate of each piece of circuit board.

▪ 24-hour customer service staff at any time response, the fastest speed to solve your order problems.

kingford one-stop PCBA OEM factory, R & D sample/small batch, SMT patch,PCB proofing, DIP welding processing,PCB board, electronic components full purchase, partial purchase one-stop PCBA manufacturing services.