There are many SMT processingmodes, such as SMT OEM and materials processing, etc. Different processing cooperation modes have different processes, and corresponding customers need to prepare different things. The biggest difference between OEM and SMT OEM is that OEM requires customers to prepare materials by themselves, while OEM can hand over board, component procurement and other links to PCBA processing plants. Quality is always the most important measure of all electronic processing plants, so is the processing of incoming materials. Shenzhen kingford adopts the most professional processing equipment, plant and production process control to ensure product quality.

SMT patch incoming material processing process

I. Both parties shall negotiate in detail on the SMT processing project and sign the cooperation contract after confirmation.

2. The customer shall provide PCB file, Bom list, component materials, etc. The PCB file and Bom list are used to confirm the component mounting direction and material accuracy.

3. Inspection and processing of incoming materials. Carry out IQC testing of materials to ensure production quality, and process materials for some components, such as material cutting pins, component molding and so on.

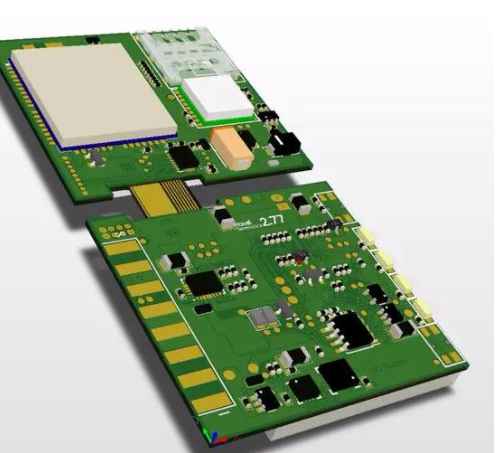

Four, online production. The first sample will be made before production, and the two sides will start mass production after confirmation. During the process of steel mesh production, solder paste printing, component mounting, reflux process and red glue process and so on.

V. Finished product inspection. The product shall be checked by the quality department, and be packaged and released after the power is qualified.

2. Esd prevention measures and precautions for PCBA processing

In the process of PCBA processing, electrostatic protection is very important. In the process and production of PCBA, good electrostatic protection can effectively protect electronic components and guarantee the quality of the patch. Then how to do electrostatic protection measures in the process and production of PCBA?

1, why should PCBA processing do electrostatic protection?

PCBA board has precision electronic components, many components are more sensitive to voltage. A shock above the rated voltage will damage these components.

However, PCBA boards damaged by static electricity are difficult to be checked step by step during functional testing. What is more fatal is that some PCBA boards function normally during testing, but when the finished products are used by customers, there will be occasional defects, which brings great hidden trouble to the after-sales service and affects the brand and reputation of the company. Therefore, in the process of PCBA, we must attach great importance to ESD electrostatic protection.

2, how to do electrostatic protection measures in PCBA processing

(1) The operator must wear electrostatic work clothes. It is forbidden to attach or wear any metal products on the work clothes. It is not allowed to take off the work clothes in the operation of electrostatic sensitive products.

(2) Wear an ESD wrist strap. Ensure that the wrist strap is in good contact with your skin and grounded reliably. Plastic boxes, erasers, cardboard, and glass are not allowed to be stacked on the ESD workbench.

(3) All components must be operated on the electrostatic safety workbench. Components entering the ESD work area must be treated according to the ESD requirements.

(4) The electrostatic sensitive elements that fall on the floor during the operation must be tested and reconfirmed before they can be used. Items that cannot be directly tested must be confirmed to be qualified before being released.

(5) When holding the sensitive element, avoid contact with its lead and wiring. Avoid electrostatic sensitive components when holding the mainboard. Some components to clean, should use anti-static brush, do not use plastic brush.

Shenzhen kingford Co., Ltd. specializes in providing integrated PCBA electronic manufacturing services, including upstream electronic components procurement to PCB production and processing, SMT patches, DIP plug-ins, PCBA testing, finished product assembly and other one-stop services.

The company gives full play to its competitive advantages in scale procurement and quality control, and has signed long-term cooperation agreements with many electronic component manufacturers at home and abroad and around the world to ensure the quality and stable supply of raw materials, and transfer the benefits to customers.