With the development of science and technology, many electronic products are developing in the direction of small and fine, which makes the size of many patch components smaller and smaller. Not only the requirements of processing environment are increasing, but also SMT processing technology has higher requirements. To do a good job of PCBA processing and SMT patch work, the processing plant needs to do at least the following three points.

PCBA processing needs to do three requirements

First, in the process of SMT processing, we all know that solder paste is needed. For the solder paste just purchased, if not immediately used, must be stored in 5-10 degrees environment. In order not to affect the use of solder paste, shall not be placed in the environment below zero.

Second, SMT equipment must be checked frequently during SMT processing. If the equipment is aged or certain parts are damaged, it is necessary to repair or replace it with new equipment in order to ensure that the patch does not bend. Only in this way can we reduce production cost and improve production efficiency.

Thirdly, in the process of SMT processing, to ensure the welding quality of PCB board, it is necessary to always pay attention to whether the setting of reflow welding process parameters is very reasonable. If the parameter setting is wrong, the welding quality of PCB board cannot be guaranteed. So generally, the furnace temperature must be tested twice a day, at least once. Only by improving the temperature curve and setting the temperature curve of welding products, can the quality of processed products be guaranteed.

How long is the PCBA processing quotation cycle?

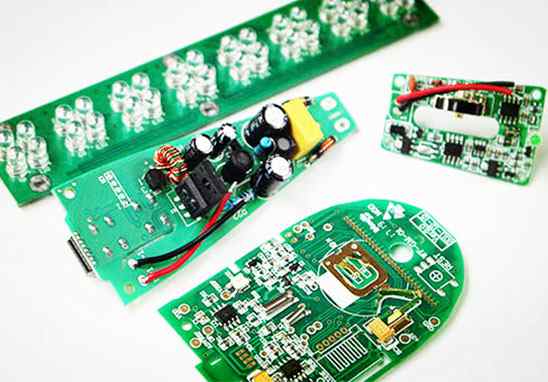

PCBA processing quotation time is the concern of many customers. In general, we say, how long does PCBA quote and process take? What are the links of PCBA manufacturing? PCBA is a general term for PCB welding materials and patch processing, including three main parts (PCB circuit board, SMT patch, component welding), so the PCBA quotation must be decided by these three parts.

PCBA manufacturing process includes component procurement, PCB production, SMT patch processing, DIP plug-in processing and PCBA a series of processes, such as testing, involving complex processes. PCBA expense =PCB board expense + parts purchase expense +SMT patch /DIP. Therefore, the time required for the comprehensive evaluation of the three parts of the quotation of PCBA is the time of the quotation of processing.

In addition to the production time of PCBA, the production cycle should also increase the time of material purchase.

I. Material purchase +PCB production cycle

Material procurement and PCB production are almost simultaneous. PCB production time is longer than material procurement time, but for some special materials or raw materials, the relatively long procurement cycle will greatly increase the production cycle of PCBA, the delivery cycle of materials is relatively unstable. The following mainly describes the PCB production time.

1. The double panel is usually enough for 4-5 days, and the batch is about 12 days

4. 7-8 days for 6-layer plate proofing, 25-30 days for batch

3. Eight-layer plate proofing generally takes 8-10 days, batch 35-40 days

Ii. SMT+DIP cycle

SMT patch and DIP plug-in production time is relatively short, but also depends on the difficulty of the process and the availability of factory orders. The normal lead time for making samples is about 1-3 days. Normal delivery time is about 5-7 days.

Iii. PCBA test

The proofing test usually takes about 1-3 days, and the batch test usually takes about 5-7 days. In practice, in the production process of PCBA, in addition to different factors, PCBA processing plants will be affected by various factors, and the production cycle of PCBA will fluctuate up and down.

Four, PCB board fee

PCB quotation required board materials and board specification documents (such as Gerber file. Coordinate file, etc.). If the information is complete, collate all the information, how much does the special process cost, plus other miscellaneous expenses can basically report a complete set of prices within 2 hours. If there are a lot of offers to wait for, that's a different story.

Besides, other costs involved in PCBA processing are mainly SMT patch processing and BOM parts procurement costs.

V. SMT patch processing fee

This module is mainly the accounting of processing costs. Generally speaking, PCBA factories calculate funds according to points. Some elements count a point, and some pins count a point. This is the biggest trick. A component has at least two pins. If a component counts a point, the price of a single point may be higher than the price of a single pin. After all, there are few points and no one is going into business at a loss, so don't look at a point. If it's expensive, don't evaluate it. In fact, this assessment can be done in less than an hour.

Vi. Component procurement fee

Parts include conventional resistance capacity and special parts. While conventional components on the market today are transparent and relatively easy to assess in price, there are some special BGA/ ics that would be more cumbersome to add to the chip because many special components would involve strict international embargoes and approval procedures. Due to price instability and other factors, the price of such components fluctuates greatly, so the quotation time is the longest and the quotation cycle is generally 3-4 days.

The above breakdown basically shows that PCBA quotes take several business days. Unless enterprises with their own stock of materials can be evaluated in a very short period of time, other enterprises may just be PCB and SMT patches faster. There are also some cases, such as many orders, the quotation is very tight, who must be the first to report, after all, the treatment of customers is equal.

Shenzhen kingford Co., Ltd. specializes in providing integrated PCBA electronic manufacturing services, including upstream electronic components procurement to PCB production and processing, SMT patches, DIP plug-ins, PCBA testing, finished product assembly and other one-stop services.

The company gives full play to its competitive advantages in scale procurement and quality control, and has signed long-term cooperation agreements with many electronic component manufacturers at home and abroad and around the world to ensure the quality and stable supply of raw materials, and transfer the benefits to customers.

We provide PCBA processing services, starting from PCB circuit board production, our own PCB manufacturers (obtained the very strict TS16949 certification of the automotive industry), pay attention to the quality of the circuit board and PCBA quality control system.

With decades of experience in purchasing electronic components, we maintain long-term cooperation with large brands to ensure the original packaging and procurement channels of components. In the process of component packaging, the selection of Qianzhu and Letai solder paste, to ensure the reliability of welding, with automatic printing press, Panasonic high-speed SMT machine, up and down eight temperature zone reflow welding, AOI automatic optical detector, can effectively ensure the reliability and quality of electronic packaging process.

In addition, perfect IPC, IPQC, OQA and other management processes, clear job responsibilities, strict implementation of IPC electronic assembly acceptance standards. For PCBA testing, we have professional engineers to perform 100% batch testing using a variety of test stands, including access, noise, amplitude, signal, temperature, humidity, drop or to perform customer detailed test plans. All efforts are aimed at becoming a refined PCBA processing factory.