Circuit board maintenance is divided into drawing maintenance and no drawing maintenance.

The maintenance method with drawings refers to the schematic diagram, analyzes the circuit principle and signal direction, and then tests the signal on the key points. In this case, it is easy to maintain the circuit, but many industrial control board circuit boards have no schematic diagram, and the PCB manufacturers will not give it to the general users as a secret.

Professional maintenance company, maintenance circuit board is almost no picture maintenance, I put the experience of these years without a picture repair circuit board with you under the exchange also hope you master to give Pointers.

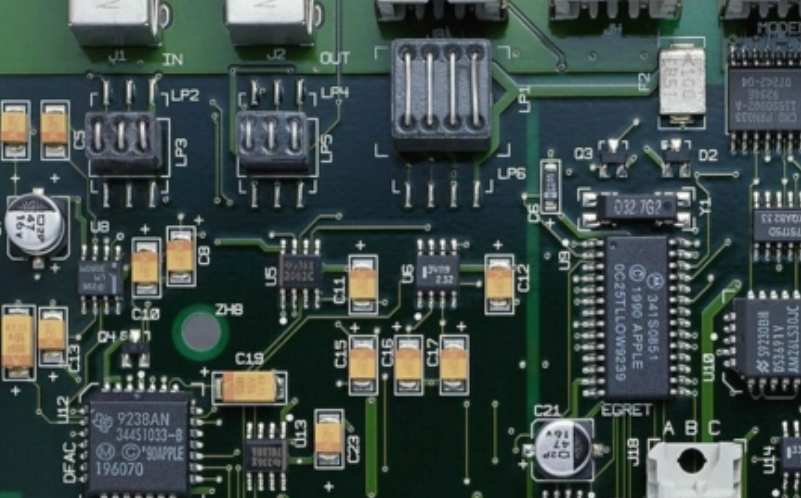

A circuit board is composed of circuit boards, components and software. In my opinion, the ability of maintenance personnel and maintenance tools such as detection are very important when repairing circuit boards. Modern circuit board if rely on a person's experience and lack of necessary tools to maintenance is difficult to do, light advocate online tester and other testing equipment without paying attention to the quality of personnel is also difficult to do.

When you repair the plate is not the same and the treatment is not the same. But the basic idea is to find out what's broken and replace it and fix it. Why don't we just replace every component on the board that we can? After the change is not good, some components are needed to debug, pay attention to the overall effect.

With online tester and other tools like mine scanning, each component made a mark check again, compare the VI curve. This can find some faults but not always fix the board, "because the chip passed by the online tester is not necessarily broken; A chip that passes the test is not necessarily undamaged." And not every component can be found in the component library, machine circuit boards are constantly updated and upgraded, so your detection tools should be constantly updated.

The quality of maintenance personnel directly affects the success or failure of maintenance. In order to repair a relatively unfamiliar PCB circuit board without any schematic diagram, a maintenance engineer who has a deep knowledge of hardware and circuit principle and structure is also required. When he sees a strange circuit board, he should carefully observe the hardware structure to determine the role of this board. Ask the customer what machine the board is mounted on when The Times what kind of warning.

In the judgment of the role of a circuit board, it is necessary to construct a block diagram of the circuit board in the mind, from the information analysis of the alarm is that the link out of the fault, may be the several components, after the replacement of the test. If you're asking the question, if the maintenance people are so good that they can't do the design, they're here to fix it? In fact, both design and maintenance are profitable, and our treatment of maintenance personnel is as good as that of design personnel. Besides, maintenance is more challenging. You face different things every day, but I still like the feeling of finding problems and fixing them.

Maintenance, the staff's approach is also very important, repair circuit board is a very fine work with a lot of components and circuit boards and easy to damage, so the operation should be very careful to need the necessary fixtures and other auxiliary tools. Disassembly, welding and so on to be skilled in not to start to think about the whole operation process, to avoid unnecessary damage. For the program of the chip, can back up as far as possible, do not allow backup do not move. If it is found that the chip with the program is damaged, and no spare or replacement chip can be found, then this PCB board cannot be repaired.

The detection of circuit boards and components requires professional detection tools, such as whether there are broken lines inside the multilayer circuit boards and whether the components are welded.

In addition to finding the broken things to repair, the most difficult thing is to test whether you have repaired and on the machine debugging, no matter how you repair, eventually to be installed on the machine tool, and sent to the customer's hand circuit board must be good, which is to be sent before the machine test, my company purchased a large number of maintenance test bench, and according to the customer's board simulation production test, To ensure that the circuit board delivered to the customer can be used normally, without delay in production.

We sell and repair parts of imported precision measuring instruments, such as electronic online tester, logic analyzer,ICT. If you are interested in repairing circuit boards, maintenance tools and instruments are essential. You should be familiar with the hardware, and pay more attention to the new components and their applications. Because every board upgrade is built on the basis of hardware. Improve your ability to repair complex PCB board with more hands.