About the Working Principle of LED Printed Circuit Board (PCB)

As the technology of the world continues to evolve, so does the technology in the field of LEDs, and LED Cases is a field that involves combining two technological approaches in order to come up with other methods that are more effective in solving the intended purpose. This LED PCB has the advantages of longevity and durability. This article will analyze in detail the working principle, design, assembly and processing methods of LED printed circuit boards (PCBs).

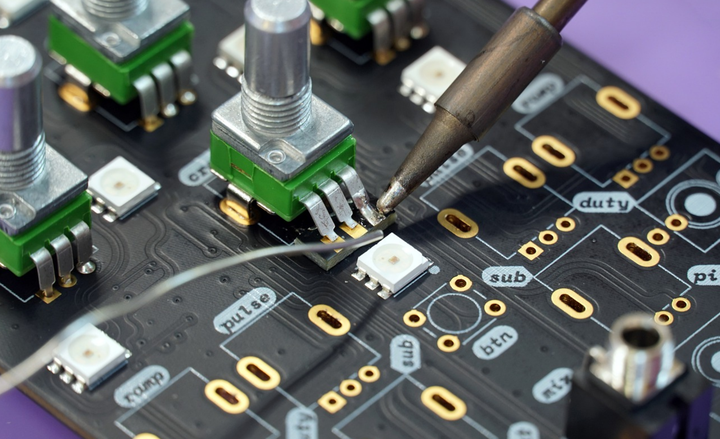

LED circuit board.jpg

What is LED Printed Circuit Board (PCB)

This is a PCB used for lighting in lighting fixtures such as modern LED bulbs. At present, the material used in the process of PCB manufacturing is metal clad copper with very good heat dissipation function. Generally speaking, we should pay attention to the fact that the single-layer LED printed circuit board PCB is composed of three layers, namely the circuit layer, the ceramic layer and the insulating layer.

LEDs are placed directly in the circuit layer on which they are mounted.

The heat emitted from the LED is quickly connected to the substrate layer for dissipation, which is done through the insulating layer and then dissipated through the substrate layer.

Copper, aluminum, and iron are the most commonly used thermal layer materials because they are readily available.

Iron cores are mostly used for high-end PCBs of motors with large heat dissipation.

LED light PCB.jpg

Working principle of LED printed circuit board PCB

The LED is installed on the surface of the circuit layer, and the heat generated by the PCB is quickly transferred to the metal base layer through the insulating layer, and then the heat is transferred out through the metal base layer to achieve the purpose of heat dissipation of the device.

Types of LED PCBs

Single layer LED PCB

This consists of a substrate layer and a conductive layer. The solder mask along with the silkscreen provides a protective function for these layers, this type of LED PCB does not have any circuit layers on the backside, and their construction is very thin and very weightless.

Double layer LED PCB

When you compare to a single layer PCB you will see that it has two copper layers which obviously makes them heavier as the number of conductive layers also increases to two. Double-layer PCBs are durable because this type of circuit layer can withstand the high current applied and has the best heat dissipation mechanism.

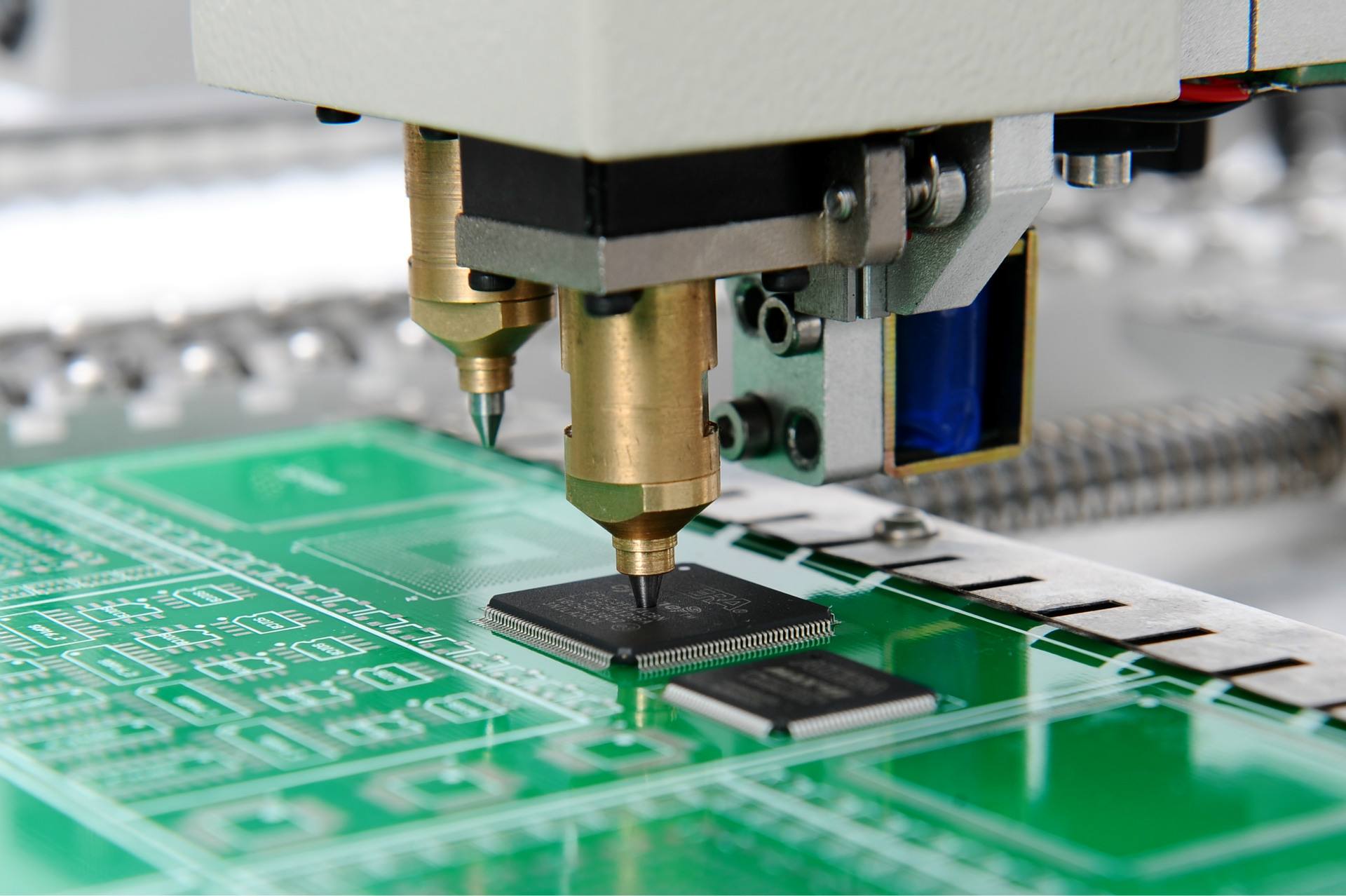

Assembly method of LED PCB

If it is an LED PCB, there are two assembly methods that can be used in the assembly. These methods are used to connect components to the board and are:

(1) Surface mount components

This method involves mounting electronic components directly into the copper layers of the circuit board. The process is highly automated, provides flexible connections, and provides space for high-density connections, which play an important role in circuits that require high connectivity and precision.

(2) Through-hole assembly

This method involves drilling holes in the PCB, mounting the components into the holes using long leads, soldering and filling them with flux. The process involves extensive inspections to ensure high precision and effectiveness. This method provides robust Durable board.

LED light PCB board.jpg

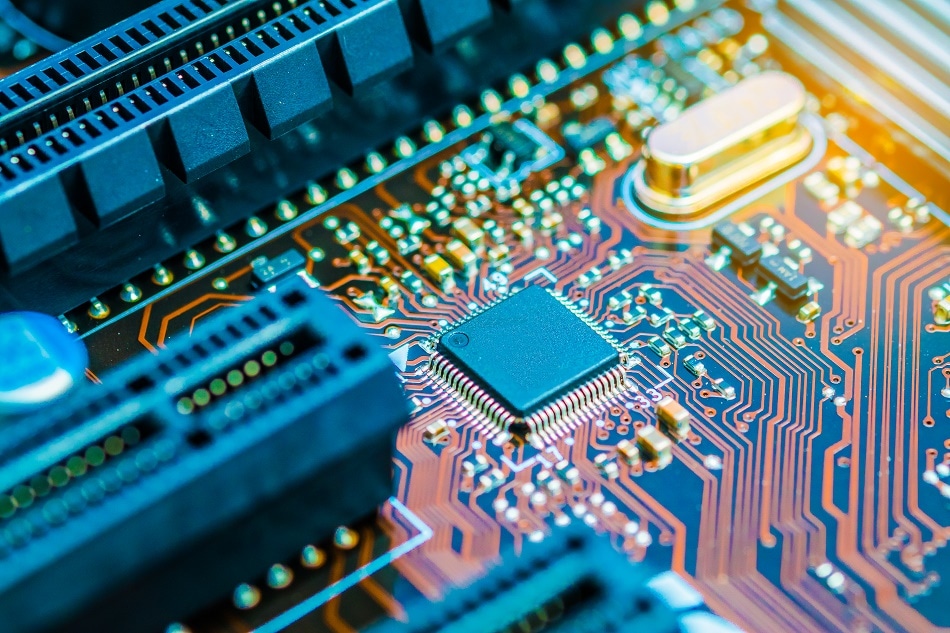

Considerations When Designing LED PCBs

Ideal Board PCB Design: You have to figure out what ideal board design you should have. In engineering, everything starts with design.

Choose the right direction: When we talk about direction, we focus on how to achieve the flow of the circuit from one end to the other, the way data and current flow in the circuit is what we call the direction.

Component placement: Besides the circuitry and the obvious LEDs, there are many other components that make up a printed circuit board. These components include resistors, capacitors, etc., and placement of components should avoid the solder side of the board because the solder is behind the through-hole side of the board.

Definition of net width design: Due to the different current consumed in the circuit, the design path will change with the size of the trace, which will also affect the net width of this design result.

Cost optimization and budget concerns: This is how the overall budget for designing a PCB will go up. Therefore, this must also be considered when proposing the LED printed circuit board PCB.

LED PCB board.jpg

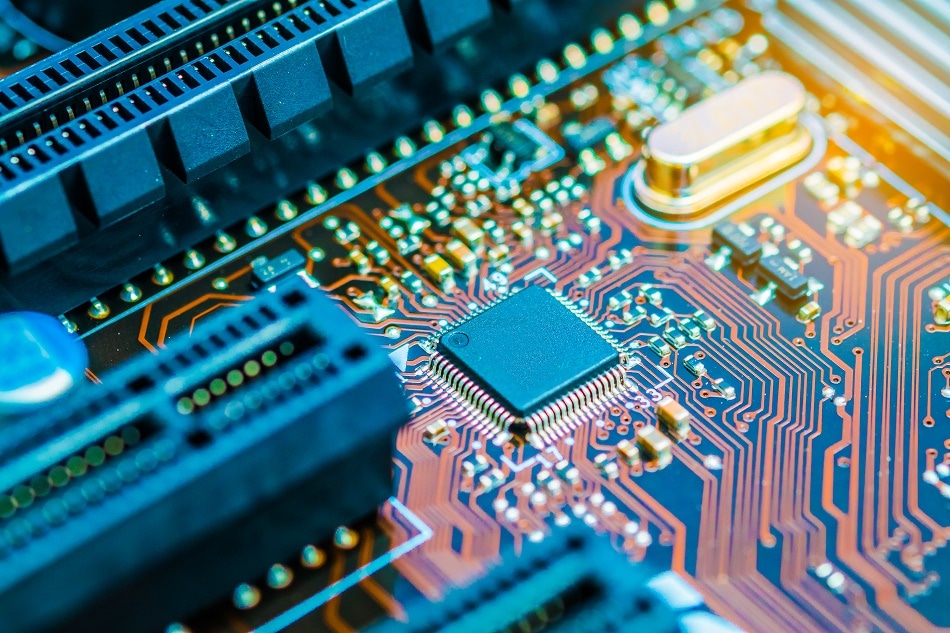

Application field of LED printed circuit board PCB

consumer lighting

This is one of the common applications for LED PCBs and they find great use in consumer lighting from flashes, lamps, spotlights, lanterns to solar lighting applications.

LED circuit board.jpg

Consumer electronics products

LEDs are also becoming common applications in electronic equipment, such as backlighting computer keyboards. Other devices incorporating this technology are smartphones, tablets and televisions.

telecommunications

Telecom displays and indicators use LED PCBS due to their durability, heat transfer capabilities and long lifespan as telecom gadgets generate a lot of heat.

transportation

LEDs have many uses in the traffic and transportation industry, from parking lights to the cars themselves. In automobiles, such PCs can be found in headlights, fog lights, brake lights, reverse lights, and indicator lights. This technology is also used in highway tunnel lighting. Modern street lighting systems are done using LED PCBs.

medical field

Medical lighting and medical equipment lighting for medical examinations and surgeries often use this type of LED PCB.