What types of consumer electronics are PCB boards suitable for

Basically, all electronic products need to use PCB boards, but not every electrical appliance needs a circuit board, simple electrical appliances may not need a circuit, such as a motor. So, what types of consumer electronics products need to use PCB boards?

1. Consumer electronics products that require integrated circuits:

These electronic products are designed to save space and make products lighter and more compact; durable and to obtain good performance, PCB boards can meet the requirements of these products for space, performance and reliability.

2. Motherboards for household appliances:

Digital TV amplifiers, mobile phones, washing machines, electronic scales, telephones, LED lights, air conditioners, refrigerators, stereos, MP3, etc.

3. For industrial equipment:

GPS, automobiles, instruments, medical instruments, aircraft, military weapons, missiles, satellites, etc.

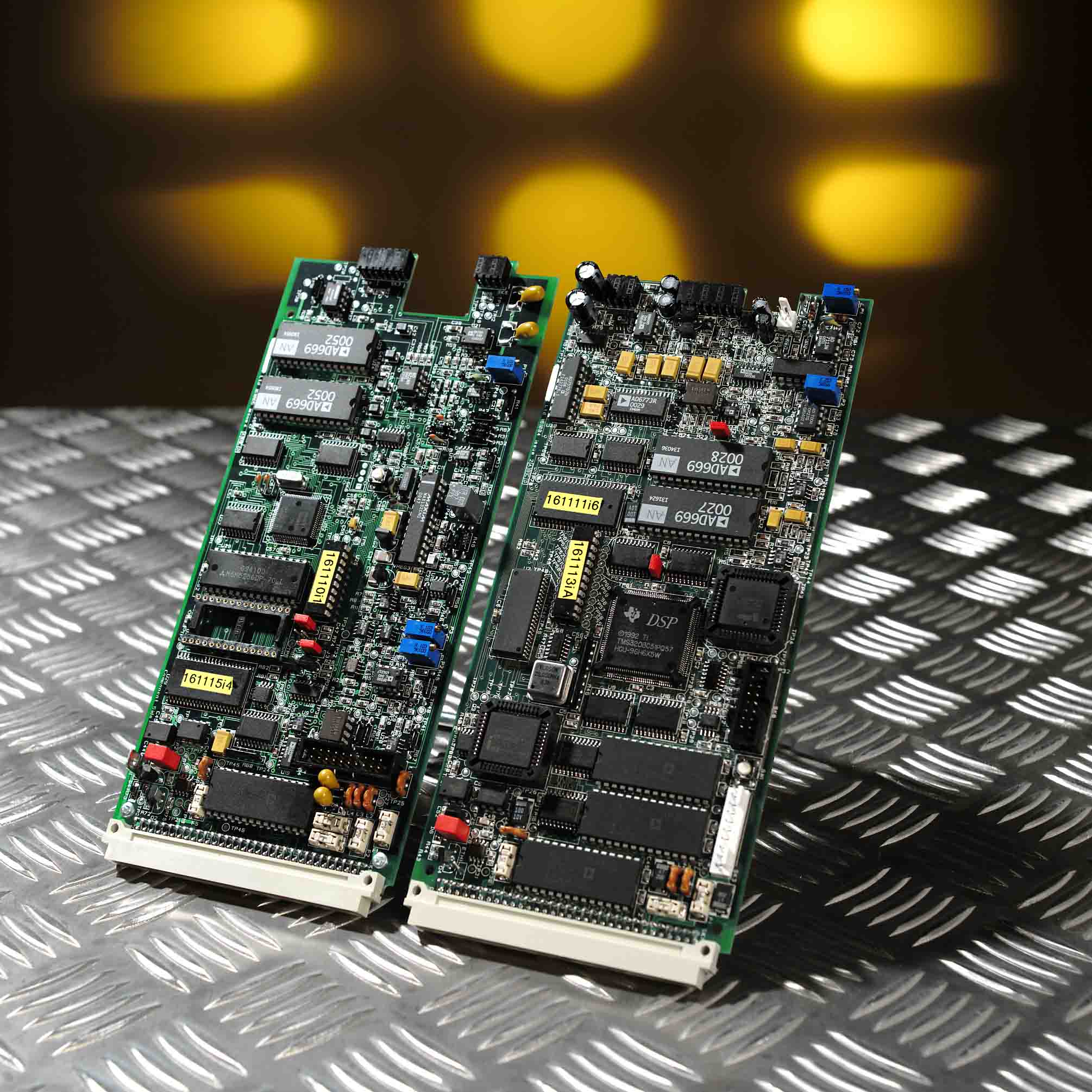

4. Types of PCB boards used in consumer electronics products:

(1) The motherboard and keyboard of the mobile phone are hard boards. The connecting cable for the slide phone or flip phone is a soft board. The remote control is usually a carbon film plate. The mobile phone board is a radio frequency circuit, a power circuit, an audio circuit and a logic circuit from top to bottom.

(2) The heated kettle has no circuit board and is directly connected with a wire bracket. Dispensers, rice cookers, and induction cookers all have circuit boards. The circuit board of the electric fan is usually used for speed adjustment, timing, display, etc., and has no actual influence on the operation of the electric fan.

What we need to admit is that the PCBA manufacturing industry is currently facing three major difficulties.

First, the weak domestic and foreign market environment after the epidemic

After the epidemic, although economic life has returned to normal, we have to admit that the three-year epidemic has brought a huge impact on the market economy. The subsequent subtle changes in people's consumption concepts have changed from advanced consumption to stable consumption. The front-end sales volume of the electronic brand market showed a downward trend, and then the overall demand for PCBA circuit boards declined.

In addition, Western countries continue to impose restrictions on the development of China's electronic technology industry, trying to restrain the continuous development of China's technology through various means, and China's electronic chip industry is bound to usher in a wave of reform.

Therefore, whether in terms of market competitiveness or market change, the future PCBA manufacturing industry will face huge challenges.

Second, big brands have higher requirements for suppliers

PCBA circuit board is an important part of electronic equipment, and its quality plays a vital role in terminal electronic products. Therefore, big brands attach great importance to and strictly demand the industry standards, production technology, testing technology, and management processes that suppliers can achieve.

Suppliers generally need to go through multiple rectifications before they can pass the qualification certification, and after providing small batches of stable quality for a period of time, they may become suppliers they continue to use.

With the continuous development of PCBA circuit boards in the direction of fineness, smallness, shortness, thinness, and lightness, brand demand for suppliers' technical processing requirements is also constantly improving.

Therefore, we must be soberly aware that under the premise of tightening demand, price wars, serious homogeneity, and increased technical requirements, suppliers must be steady in terms of product quality and management processes, and gradually realize their own quality and technical barriers. industry goals.

Third, the rising cost of production

In recent years, the prices of PCBs and components have risen wildly. Faced with frequent price increases of raw materials, it is undoubtedly worse for some foundry companies with imperfect supply chains. The stable and large-scale production orders of OEM enterprises provide a solid foundation for raw material negotiation. Therefore, the continuous establishment of a perfect supply chain system is a very important part of cost control and reduction.

In addition, in terms of production process, staffing, and equipment maintenance, it is also necessary to carry out internal optimization of the enterprise, rational use of time, and elimination of material waste, etc., are important means for enterprise cost control and reduction.

As a traditional PCBA manufacturer, how to enter the industry in the wave of China's chip era is a topic that every entrepreneur must think deeply about.

The picture comes from the Internet, if there is any copyright, please contact to delete it!

In recent years, mainland China has unique advantages in the manufacturing industry. With the continuous rise of personnel and other manufacturing costs, and the continuous rise of the Southeast Asian market, part of the market has moved to foreign countries with the goal of reducing costs, leaving domestic manufacturing companies. It is necessary to re-layout, from homogenization to high-end development based on price and service.

With the development of information technology, microelectronics technology has also made new progress. The transformation of assembly technology from surface mount to micro assembly will further promote the development of PCBA manufacturing in the direction of short, thin, fine, light and small.

Correspondingly, the market will put forward new requirements for PCBA circuit board technology, and there will be an era of change in terms of materials, technology, processes, management, and services. On the other hand, for PCBA manufacturers, it is necessary to gradually realize the business model of transforming from OEM to labor and material.

The establishment of a high-quality supply chain requires continuous hard work and scientific management, which does not happen overnight. In order to ensure the quality of materials and components, enterprises also need to further equip professional testing instruments and talents. As a result, the possible risks in the process increase.

![» Introduction to PCB Design July 11 / PCB电路板设计入门 7月11号 新车间 [XinCheJian]](https://xinchejian.com/wp-content/uploads/2015/07/pcb.jpg)

It is both a challenge and an opportunity. Whether we can grasp the needs of the times and constantly update ourselves iteratively, so that enterprises can develop in the direction of market demand, has become the core proposition of our manufacturing industry in the future.