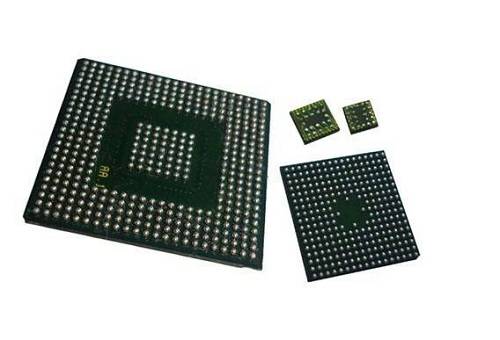

BGA component assembly

1. PBGA (PLASTICBALL GRID ARRAY) plastic package BGA

Its advantages are:

①Good thermal matching with epoxy resin circuit board.

② Solder balls participate in the formation of solder joints during reflow soldering, and the requirements for solder balls are loose.

③It can be centered by the edge of the package when mounting.

④ low cost.

⑤ Good electrical performance.

Its disadvantages are: sensitivity to moisture and lower density of solder ball array than CBGA

2. CBGA (CERAMIC BGA) ceramic package BGA

Its advantages are:

①The reliability of packaged components is high.

②The coplanarity is good, and the solder joints are easy to form, but the solder joints are not parallel to each other.

③Not sensitive to moisture.

④ High packaging density.

Its disadvantages are:

① Due to the different thermal expansion coefficients and poor thermal matching with the epoxy board, solder joint fatigue is the main failure mode.

② It is difficult to align the solder balls at the edge of the package.

③The packaging cost is high.

3. TBGA (TAPEBGA) carrying BGA

Its advantages are:

①Although there is local stress in the chip connection, the overall thermal match with the epoxy board is better.

② Mounting can be aligned through the edge of the package.

③It is the most economical packaging form.

Its disadvantages are:

① Sensitive to moisture.

② sensitive to heat.

③Multiple rounds of different materials have an adverse effect on reliability.

BGA has been widely used in electronic products, but in actual production applications, PBGA is the majority. The biggest disadvantage of PBGA is that it is sensitive to moisture. If PBGA absorbs moisture,

PBGA will easily produce "popcorn" phenomenon during welding, which will lead to PBGA failure. There are many articles in many literatures to improve the quality of BGA process. Here we only focus on the shortcoming of PBGA being sensitive to moisture, and discuss the methods to prevent PBGA from failure due to moisture absorption in the relevant process links of the actual production process.

1. Acceptance and storage of PBGA

PBGA is a moisture-sensitive component. It is packaged in vacuum when it leaves the factory, but it is easy to damage the vacuum package during transportation and turnover, resulting in moisture in the component and oxidation of the solder joints.

Therefore, when the component enters the factory for acceptance,

the packaging state of the component must be As an inspection item, strictly separate vacuum-packed and non-vacuum-packed components.

Vacuum-packed components should be stored according to their storage requirements and used within the shelf life. Non-vacuum components should be stored in a low-humidity cabinet as required to prevent PBGA Moisture absorption and pin oxidation.

At the same time, it is controlled according to the principle of "first in, first out" to minimize the risk of component storage.

2. Selection of PBGA dehumidification method

Damp PBGA should be dehumidified before going into production.

BGA dehumidification usually has two types: low-temperature dehumidification and high-temperature dehumidification. Low-temperature dehumidification uses a low-humidity cabinet for dehumidification. Dehumidification is time-consuming, usually under 5% humidity, it takes 192 hours.

High-temperature dehumidification uses an oven for dehumidification, and the dehumidification time is relatively short. Usually under the condition of 125 degrees Celsius, it takes 4 hours. In actual production, after high-temperature dehumidification of those non-vacuum-packed components,

they are stored in a low-humidity cabinet to shorten the dehumidification cycle. It is recommended to use low temperature dehumidification instead of high temperature dehumidification for the PBGA whose humidity card shows that the humidity exceeds the standard. Because the temperature of high temperature dehumidification is high (greater than 100 degrees Celsius) and the speed is fast, if the humidity of the component is high, it will be due to the rapid gasification of moisture. lead to component failure.

3. Control of PBGA at the production site

When PBGA is used on the production site, after the vacuum-packed components are unpacked, the humidity card on the package must be cross-checked. If the humidity mark on the humidity card exceeds the standard,

it cannot be used directly and must be dehumidified before use.

When receiving non-vacuum-packed components at the production site, the humidity tracking card of the material must be checked to confirm the humidity state of the material.

Non-vacuum-packed components without a humidity tracking card cannot be used.

At the same time, strictly control the use time and environment of PBGA on site. The use environment should be controlled at about 25 degrees Celsius, and the humidity should be controlled within 40-60%.

The use time of PBGA on site should be controlled within 24 hours. PBGA exceeding 24 hours must be Re-dehumidify

4. PBGA rework

BGA rework usually uses BGA rework station (BGArework station). If the PCBA with PBGA is reworked on the production site, if it is placed for a long time, the PBGA is easy to absorb moisture, and the humidity state of the PBGA is also difficult to judge.

Therefore, before the PBGA is removed, the PCBA with the PBGA must be dehumidified to avoid components. Failure and scrapping in mid-term makes BGA ball placement and reassembly futile.

Of course, there are many process links and reasons that lead to BGA failure in the SMT process,

such as ESD, reflow soldering, etc. In order to reduce the failure of BGA in the SMT process, comprehensive control in many aspects is required. For PBGA,

the process links related to moisture absorption of components are often ignored in actual production, and the problems are relatively hidden, which often cause many obstacles for us to improve the process and improve the quality of the process. Therefore, for the shortcomings of PBGA that are sensitive to moisture ,

in the production process, starting from the above aspects and taking effective countermeasures can better reduce the failure of PBGA, improve the quality of PBGA process, and reduce production costs