Your OEM/EMS solution provider Click to download to view

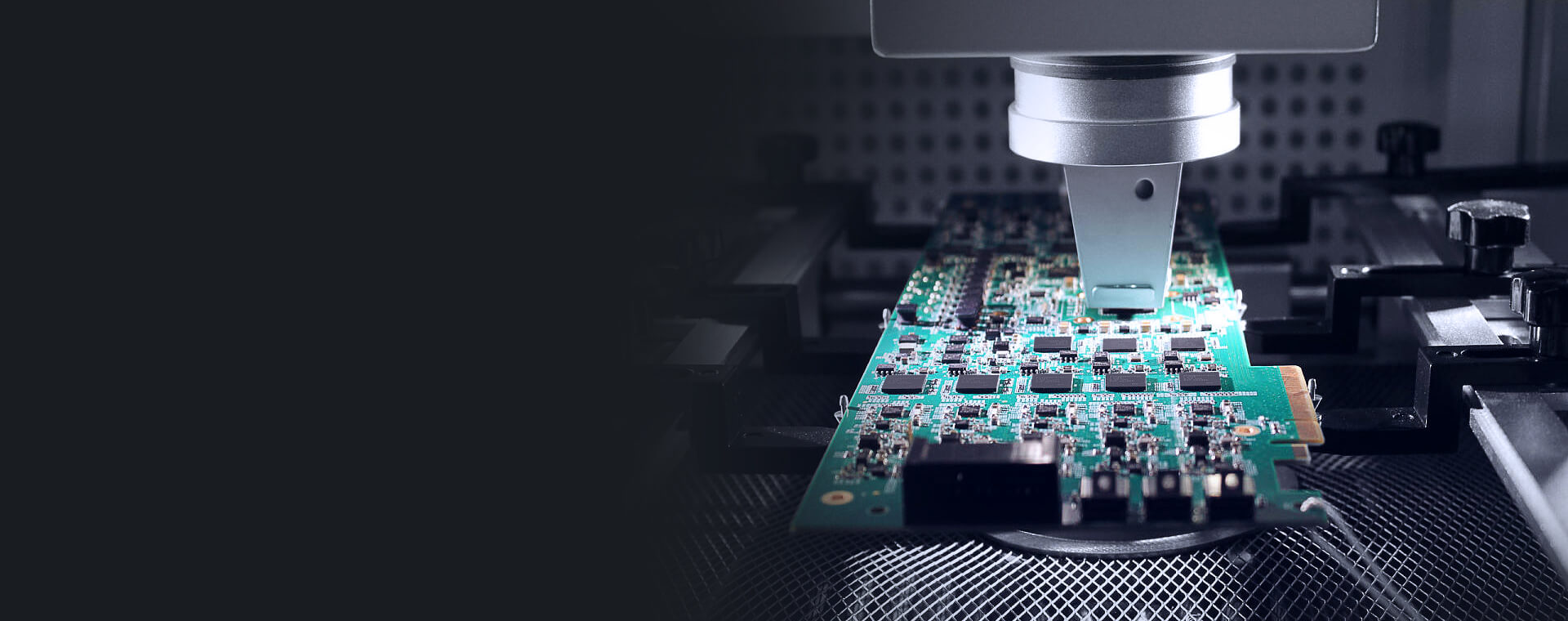

Strictly follow the IPC standard control to ensure the qualified rate of shipment quality. If the customer has a bad problem caused by non-PCB external factors in the process of standardizing the use of the product, Kingford promises to repair it for free within one year. All PCB circuit boards are strictly inspected, in addition to manual visual inspection, we use automatic testing, testing equipment, such as AOI optical inspection, FAI first article inspection system, X-ray inspection, ICT testing, plug-in online visual inspection instrument, thermal Infrared detector, high and low temperature tester, PCBA function test, online and offline program burning, oscilloscope, FCT function test, program burning and other equipment.

|  |  |  |

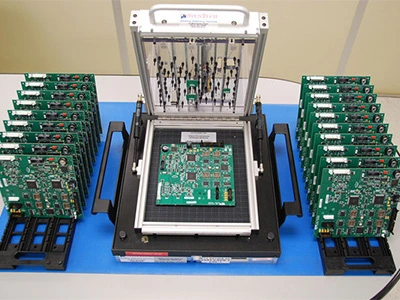

| AOI automatic optical inspection is based on the principle of optics, comprehensively adopts various technologies such as image analysis, computer and automatic control, to automatically detect and process PCB defects encountered in production, and can efficiently and accurately screen out defective products to avoid harmful Defective PCBs flow to the client or the next process. | FAI first article detection system, high-precision 10-level sorting; PASS/FAIL indication plus voice broadcast; serial and parallel equivalent mode, automatic selection of function range; L-RDC simultaneous test, one-key screen capture function, data recording function. Automatically generate the first article report, greatly improving the efficiency of first article confirmation, ensuring that the first article is correct and preventing errors. | ICT test, according to the PCB test plan provided by the customer, includes test points, programs, PCB test racks, ICT/FCT fixtures, and test steps to simulate the input and output of PCB circuits and measure whether their values meet the standards. | X-RAY inspection equipment uses the change of light intensity after X-Ray penetrates materials with different densities to produce contrast effect images to detect the internal structure of ultra-fine pitch and ultra-high-density PCB circuit boards, and then can be used without damaging the PCB. In the case of circuit boards, observe areas inside the PCB that may have problems, such as bridges, missing chips, misalignment, open circuits, etc. |

|  |  |  |

Three-dimensional solder paste inspection (SPI), effectively checks the volume, area, height, XY offset and shape of the solder paste printed on the PCBA. Detect defects such as missed printing, less tin, more tin, continuous tin, deviation, poor shape, board surface contamination, etc. in time, and eliminate the problems. | Plug-in online visual inspection instrument, AOI automatic optical inspection, based on optical principles, comprehensively uses image analysis to accurately screen out defects such as wrong parts, missing parts, reverse, multiple parts, and offsets in the DIP process. Effectively avoid defective PCBA output to the client or post-production process. | X-ray Coating Thickness Gauge, a multi-functional testing instrument, can conduct comprehensive and accurate detection and analysis of coatings, which helps to improve product quality and production efficiency. | High and low temperature tester, -70-150°C thermal shock temperature, 20%-98% humidity adjustment. It is used for high and low temperature reliability test. To test the performance indicators of parts and materials of related products such as electronics, automobiles and motorcycles, aerospace, rubber, plastics, metals, ship weapons, colleges and universities, scientific research units, etc. under high and low temperature changes. |

|

|

|

|

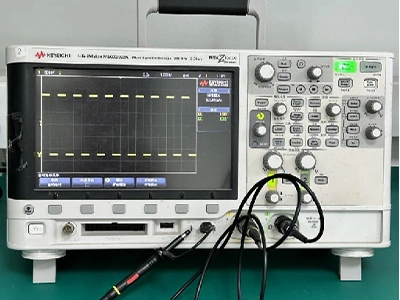

| PCBA function test, full function coverage test, to ensure that each piece of product function is reliable and stable. | On-line and off-line program programming, automatic and manual injection of soul into programs for EPROM, EEPROM, NOR FLASH, SPROM, and NAND FLASH chip programming. | Oscilloscope, 4-channel 200M 1G sampling rate high-precision digital display oscilloscope. Product research and development, equipment debugging and maintenance must-have products. Let the problem go nowhere. | FCT function test, according to the PCB test plan provided by the customer, includes test points, programs, PCB test racks, ICT/FCT fixtures, and test steps to simulate the input and output of PCB circuits and measure whether their values meet the standards. |