One - stop Electronic Manufacturing Services(EMS) Solution provider

- PCB manufacturing equipment

- FPC Fabrication Capability

PCB Drilling machine

PCB pattern plating line

PCB solder mask expose machine

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask scrubbing line

PCB Flying Probe Test (FPT)

Fully automatic exposure machine

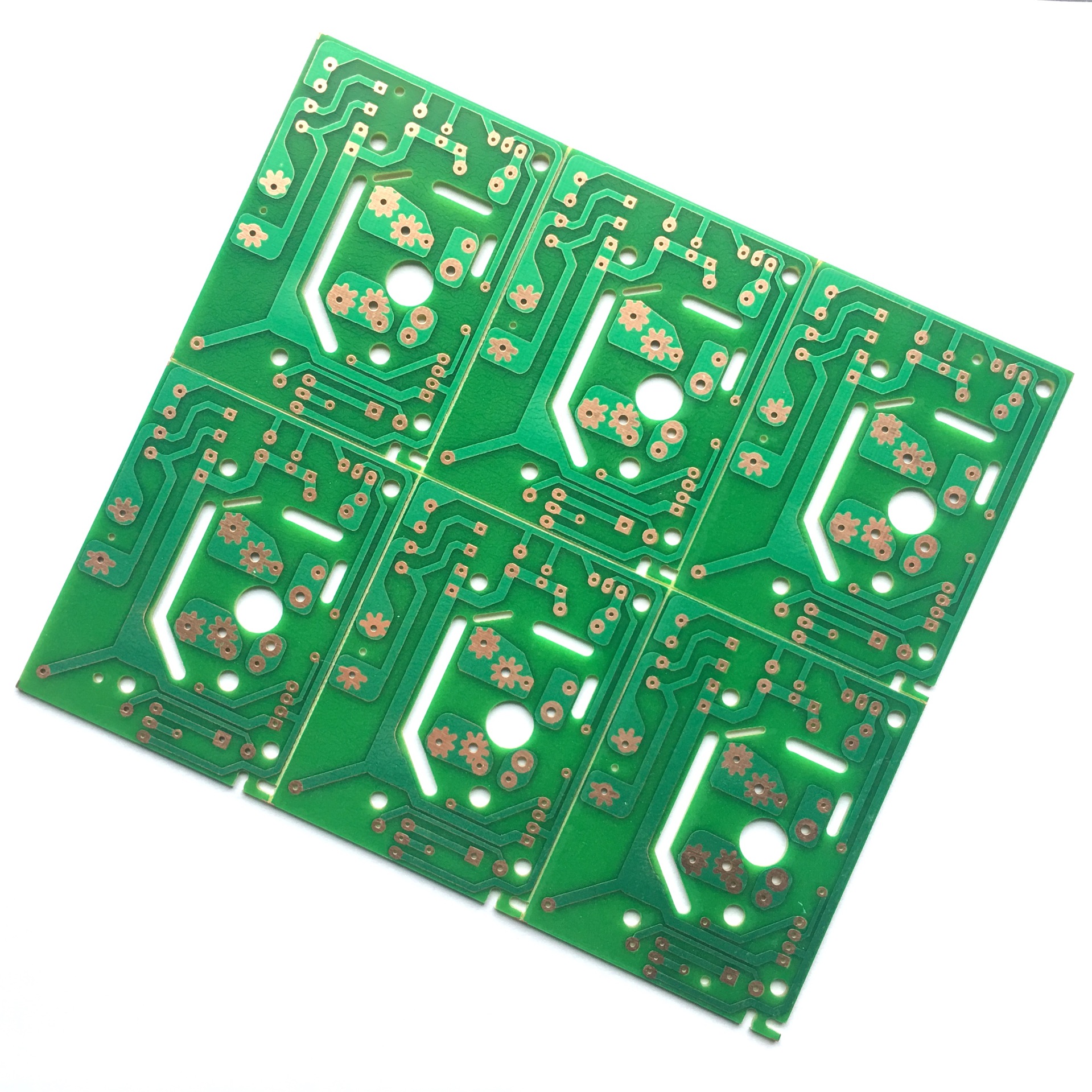

| Item | Usual | Unusual | |

| PCB Layers | 1 – 12 layers | ||

| Laminate | Material | Flexible part: DuPont PI, Shengyi PI | ||

| Rigid part: PI/FR4 | |||

| FR4, for lead-free welding | |||

| low-loss material | |||

| Halogen free | |||

| Special materials: Rogers/Arlon/Nelco/Taconic etc | |||

| PTFE | |||

| Polyimide | |||

| Delivery Size | Delivery Size | 570X610mm | 570X610mm |

| Production size | 610X640mm | 610X640mm | |

| Board Thickness | thinnest | 0.25 mm | 0.20 mm |

| thickest | 5.00 mm | 5.50 mm | |

| Finished board thickness tolerance | ±2mil(±0.04m) | ||

| Copper Thickness | Inner Layer | 1/3-28 OZ | 1/3-30 OZ |

| Outer Layer | 1/7-28 OZ | 1/7-30 OZ | |

| Inner Line | Minimum line width | 50μm | 50μm |

| Minimum line spacing | 75μm | 50μm | |

| Outer Line | Minimum line width | 75μm | 50μm |

| Minimum line spacing | 75μm | 50μm | |

| Min. mechanical Via hole, minimum pad | inner Layer | 0.45 mm | 0.40 mm |

| Outer Layer | 0.40 mm | 0.35 mm | |

| Laser Via hole minimum pad | inner Layer | 0.25 mm | 0.23 mm |

| Outer Layer | 0.25 mm | 0.23 mm | |

| Thickness to diameter ratio | LBMV | 1:01 | 1:01 |

| MVTH | 1:12 | 1:16 | |

| Min. dielectric thickness | Inner core board | 0.025 mm | 0.025 mm |

| Prepreg | 0.05 mm | 0.05 mm | |

| Solder resist | min. spacing | 60 μm | 40 μm |

| Min. Solder resist bridge | 75 μm | 65 μm | |

| Buried capacitance | Insulation thickness: 14 μm | ||

| unit-area capacitance: 6.4 nF/in2 | |||

| Breakdown voltage: >100V | |||

| Buried resistor | Resistance per unit area(ohms/sq.) : 25, 50, 100, 200 | ||

| Impedance control accuracy | 10% | 5% | |

| Plug hole | ink plughole | ||

| resin plug holes | |||

| copper slurry plughole | |||

| Min Tracing/Spacing | 2.5mil/2.5mil | ||

| Min. Annular Ring | 4mil | ||

| Min. Drilling Hole Diameter | 8mil(0.15mm) | ||

| Min. mechanical drilling | 0.15 mm | 0.15 mm | |

| Laser aperture | 0.10-0.2 0mm | 0.10-0.20 mm | |

| Min. finished via diameter | 6mil(0.15mm) | ||

| Tolerance of dimension | 3mil(0.076 mm) | ||

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow | ||

| Silkscreen Color | White, Black, Yellow | ||

| Surface Finish | OSP | ||

| HASL(Hot Air Solder Leveling) | |||

| HASL Lead-Free | |||

| Flash Gold | |||

| ENIG (Electroless Nickle/Immersion Gold) | |||

| Immersion Tin | |||

| Immersion Silver | |||

| Special technologies | Impedance Control+/-10% | ||

| Gold fingers | |||

| Stiffener (PI/FR4) | |||

| Peelable solder mask | |||

Kingford

Why choose us?

Kingford

Industries we serve

Kingford

Flexible Circuit Board FAQs

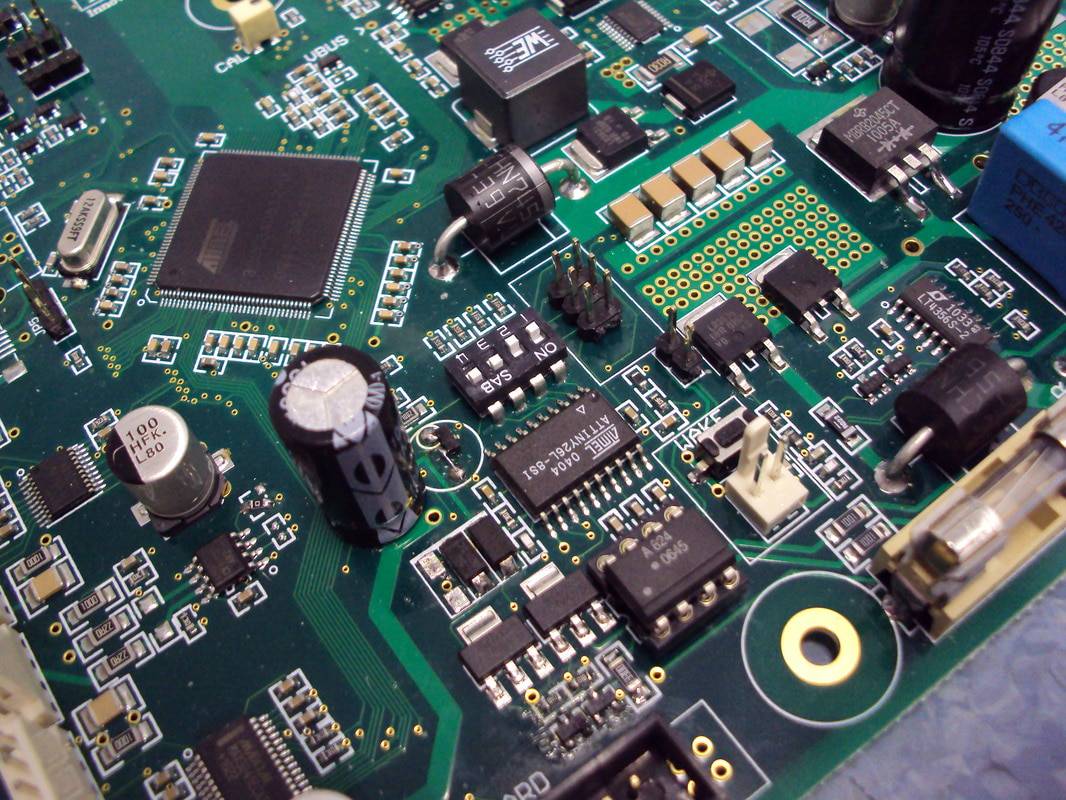

The main conductive material for flexible PCBs is copper or copper foil, and alloys are sometimes used, including aluminum, nickel, gold, and silver. In addition to being conductive, the conductor layer should be resistant to flex.

Flexible circuit boards are used in cameras, personal entertainment devices, calculators or motion monitors.

A flexible printed circuit board, also known as a flex print or flex circuit, is a special type of circuit board that you can bend into a desired shape. They are widely used in high density and high temperature applications

We use cookies to optimize our website and our service.