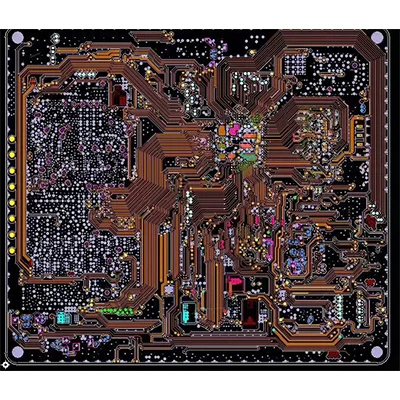

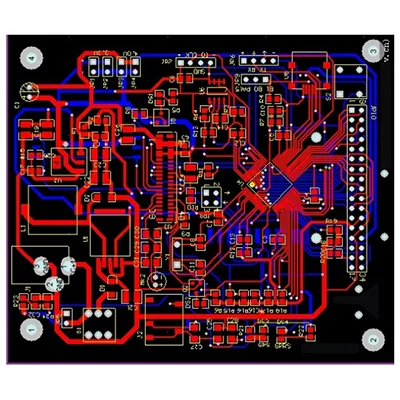

Communication high-speed signal PCBA design

Name: Communication high-speed signal PCBA design

Plate: TG170 /TG180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

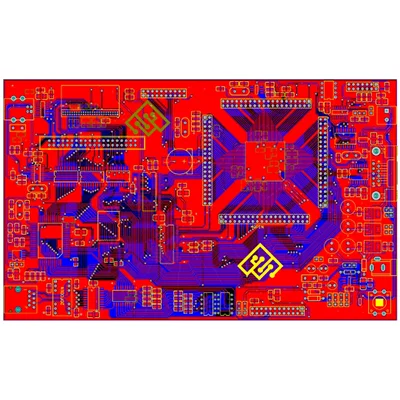

Arbitrary Interconnect HDI PCBA Design

Name: Arbitrary Interconnect HDI PCBA Design

Plate: TG170 /TG180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

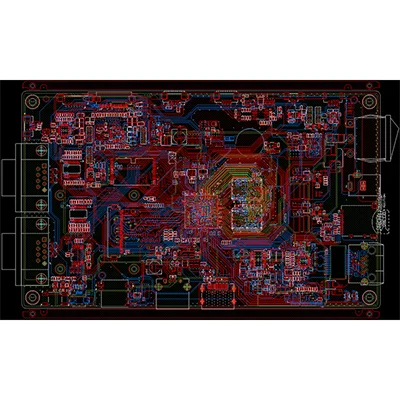

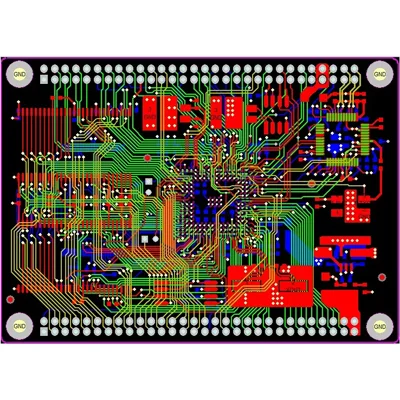

10-layer second-order HDI PCBA design

Name: 10-layer second-order HDI PCBA design

Plate: TG170 /TG180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

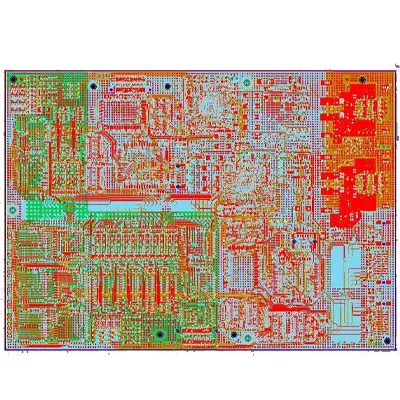

16-layer two-stage high-precision PCB design

Name: 16-layer two-stage high-precision PCB design

Plate: TG170 /TG180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

8-layer second-order HDI PCBA design

Name: 8-layer second-order HDI PCBA design

Plate: TG170 /TG180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

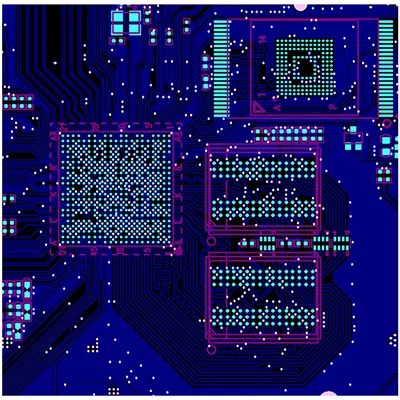

Six-layer HDI PCBA design and production

Name: TG180 High Density Interconnector PCBA Design

Plate: TG170 /TG180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Screen printing color: black, white, red, green, etc.

Surface treatment: lead/lead-free tin spray, ENIG, silver, OSP

Service: Provide OEM service

Certificate: ISO9001.ROSH.UL

Automation Equipment HDI PCBA Design

Name: Automation Equipment HDI PCBA Design

Sheet: IT180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Surface treatment: rosin spray tin electric gold, anti-oxidation, chemical gold, carbon oil

Service: Provide OEM service

4-layer HDI switch circuit board design

Name: 4-layer HDI switch circuit board design

Sheet: IT180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Surface treatment: rosin spray tin electric gold, anti-oxidation, chemical gold, carbon oil

Service: Provide OEM service

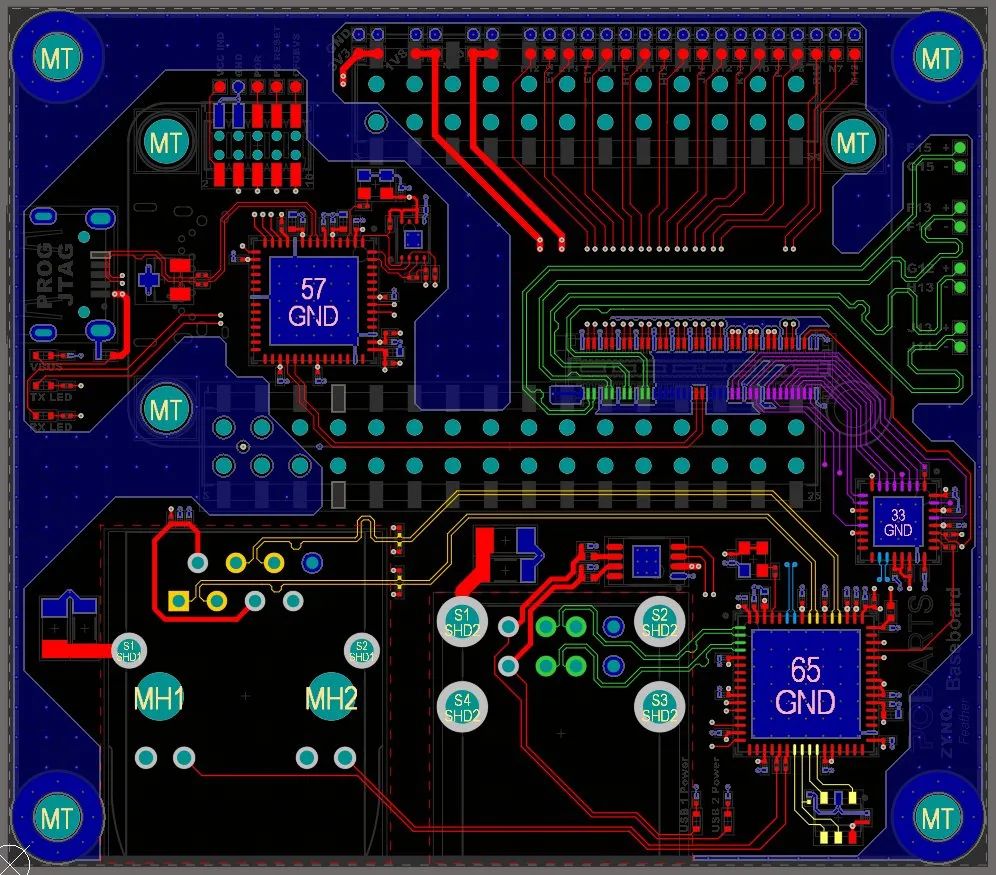

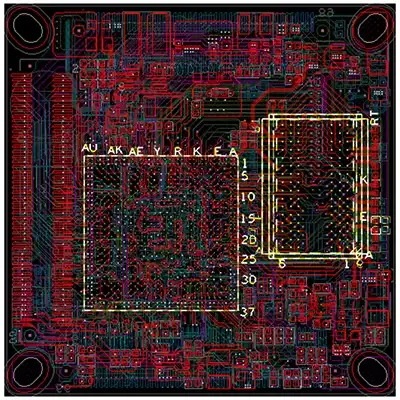

- PCB Design Capabilities

| PCB Design&Layout Capabilities | |||

| Min.trace width: | 2.5mil | Min.trace spacing | 2.5mil |

| Min.Vias: | 6mil(4mil laser drilling) | Max.layer | 48L |

| Min.BGA spacing | 0.35mm | Max.BGA Pin | 3600pin |

| Max.high-speed signal | 40 GBPS | Fastest delivery time | 6 Hours/ Item |

| HDI Highest layer | 22 L | HDI Highest layer | 14 L any layer HDI |

| PCB Design&Layout lead time | |||

| Number of pins on the board | 0-1000 | Design lead time (working days) | 3-5 days |

| 2000-3000 | 5-8 days | ||

| 4000-5000 | 8-12 days | ||

| 6000-7000 | 12-15 days | ||

| 8000-9000 | 15-18 days | ||

| 10000-12000 | 18-20 days | ||

| 13000-15000 | 20-22 days | ||

| 16000-18000 | 22-25 days | ||

| 18000-20000 | 25-30 days | ||

| Ultimate delivery capacity | 10000Pin/7 days | ||

| PS: The above delivery date is the regular delivery date, and the accurate design delivery date needs to be comprehensively evaluated according to the number of components, difficulty, layers and other factors of the circuit board! | |||

As products are miniaturized, many designs push the physical limits of PCB manufacturability. In this context, the importance of DFM inspection is increasing.

Multilayer PCB Design FAQ

Some DFM problems include: problems due to copper/solder mask debris on the plane, problems due to no gap pads on the plane, problems due to insufficient annular rings, problems due to copper being too close to the edge of the board.

HDI PCB Design High Density Interconnector PCB Design. Circuit boards with higher wiring density per unit area compared to traditional circuit boards are called HDI PCBs.