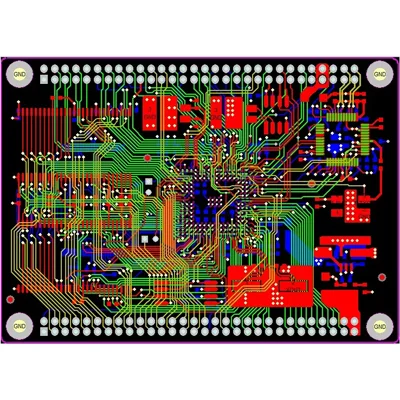

4-layer HDI switch circuit board design

Name: 4-layer HDI switch circuit board design

Sheet: IT180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Surface treatment: rosin spray tin electric gold, anti-oxidation, chemical gold, carbon oil

Service: Provide OEM service

4-layer HDI PCB is widely used in:

Telecom module

wireless module

LED display module

HDI PCB (1+N+1): This is the simplest HDI PCB layout design structure, suitable for BGAs with fewer I/Os. It features fine lines, micro vias, and registration technology capable of 0.4mm ball pitch for excellent mounting stability and reliability, and may contain copper-filled vias. It is qualified material and finish for lead free process

Name: 4-layer HDI switch circuit board design

Sheet: IT180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Surface treatment: rosin spray tin electric gold, anti-oxidation, chemical gold, carbon oil

Service: Provide OEM service

- Previous:No

- Next:Automation Equipment HDI PCBA Design