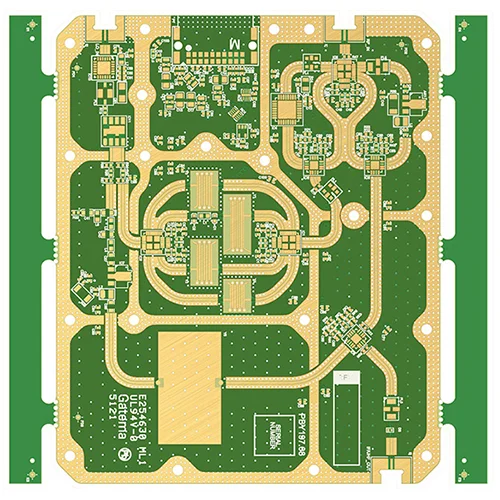

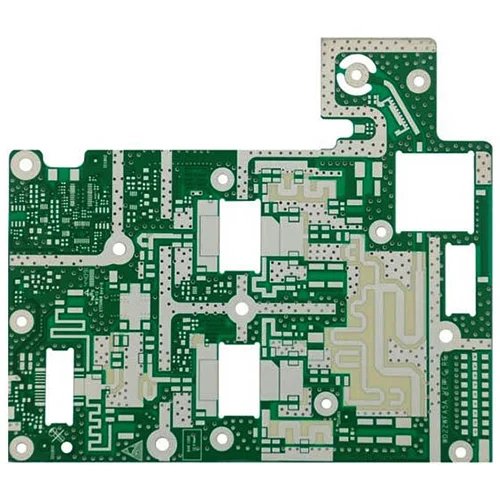

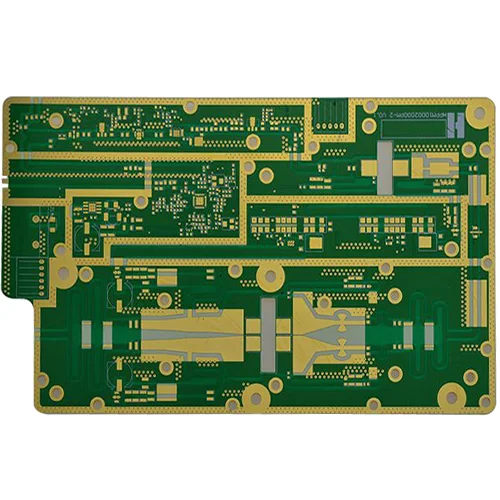

Rogers RO4350B PCB

Name: Rogers RO4350B PCB

D K: 3.48+/-0.05

Layer: 2L

Dielectrics Thickness: 0.762mm (30mil)

Finished Thickness: 0.85mm

Material Copper Thickness: ½(17μm)HH/HH

Finished Copper Thickness: 1OZ (35μm)

SurfaceTreatment: Immersion Gold

Application: Instrument PCB, Radio Frequency PCB, Radar Gauges PCB

Rogers RO4350B PCB laminates tightly control the dielectric constant (Dk) and maintain low losses while using the same processing methods as standard epoxy/glass. RO4350B laminates cost a fraction of the cost of traditional microwave laminates and do not require special through-hole processing or processing procedures like PTFE-based materials. These materials are UL 94 V-0 rated for active equipment and high power RF designs.

feature

Dk is 3.48 +/- 0.05

0.0037 dissipation factor at 10 GHz

Low Z-axis thermal expansion at 32 ppm/°C benefit

Processes such as FR-4 are less expensive to manufacture

Competitive pricing

Excellent dimensional stability

RO4350B™ Laminate

Rogers RO4350B material is a proprietary woven glass reinforced hydrocarbon/ceramic with electrical properties approaching the manufacturability of PTFE/woven glass and epoxy/glass.

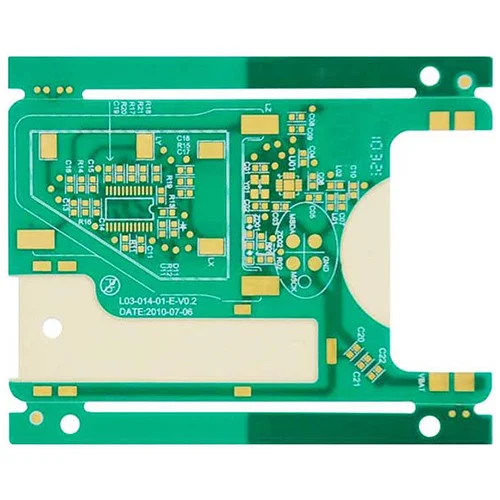

Name: Rogers RO4350B PCB

D K: 3.48+/-0.05

Layer: 2L

Dielectrics Thickness: 0.762mm (30mil)

Finished Thickness: 0.85mm

Material Copper Thickness: ½(17μm)HH/HH

Finished Copper Thickness: 1OZ (35μm)

SurfaceTreatment: Immersion Gold

Application: Instrument PCB, Radio Frequency PCB, Radar Gauges PCB