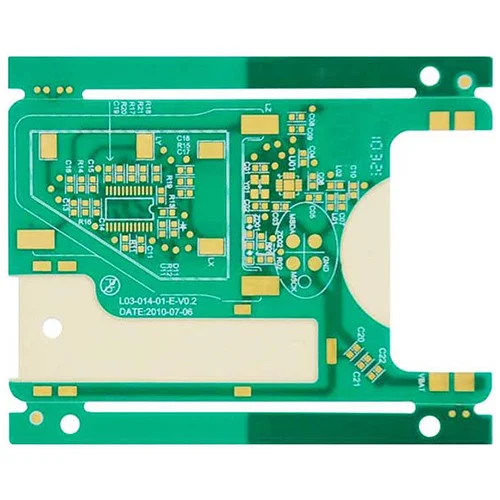

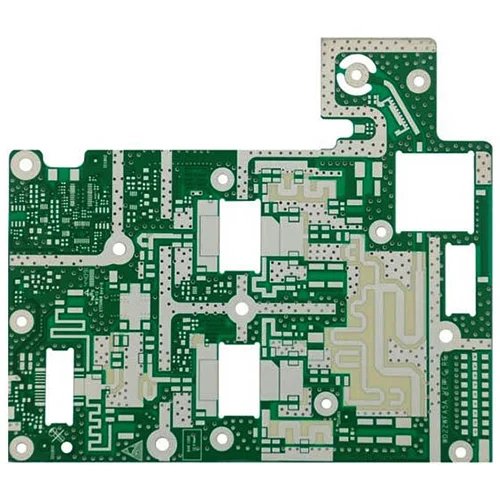

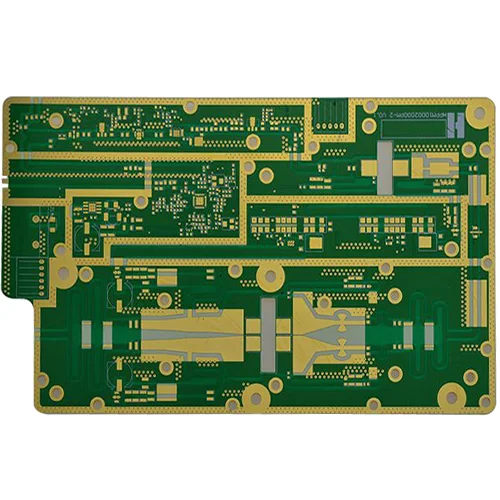

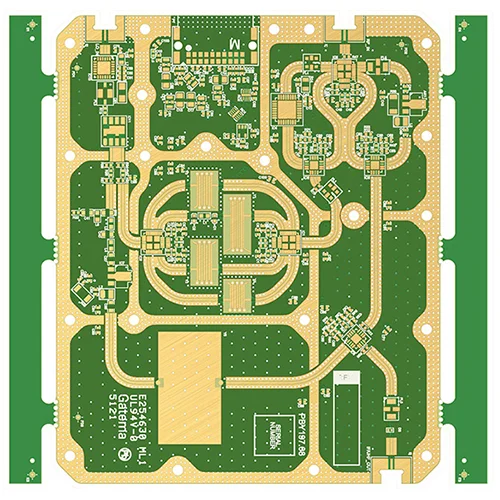

Rogers RO4350B Radio Frequency PCB(RFPCB)

Name: Rogers RO4350B RF PCB (RFPCB)

DK: 3.48+/-0.05

Layers: 4 layers

Dielectric thickness: 0.254mm (20mil)

Finished thickness: 0.8mm

Material Copper Thickness: ½(17μm)

Finished copper thickness: 1OZ (35μm)

Surface Treatment: Immersion Gold

Application: Instrument PCB, RF PCB, Radar Instrument PCB

rogers ro4350b high frequency circuit board

Ro4350b is a patented hydrocarbon resin system/ceramic filler reinforced with glass woven cloth. Its electrical properties are very close to PTFE/woven glass cloth materials, and its processability is similar to epoxy resin/glass cloth materials.

The ro4350b can use standard epoxy/glass cloth processing techniques while offering tightly controlled dielectric constant and loss at a fraction of the price of traditional microwave materials. No special through-hole pretreatment or manipulation procedures are required like PTFE-based microwave materials.

Ro4350b material has passed UL 94V-0 fire rating for active equipment and high voltage RF designs.

Real project show:

Rogers RO4350B Advantages:

1. Low DF

2. Low DK fluctuates with temperature

3. Low Z-axis thermal expansion coefficient

4. Low internal expansion coefficient

5. Low DK tolerance

6. Stable electrical characteristics at different frequencies

7. Easy mass production and multi-layer hybrid FR4, cost-effective

Typical applications: Cellular base station antennas and power amplifiers, microwave point-to-point connections (P2P), automotive radar and sensors, radio frequency identification (RFID) tags, LNBs for live broadcast satellites

Name: Rogers RO4350B RF PCB (RFPCB)

DK: 3.48+/-0.05

Layers: 4 layers

Dielectric thickness: 0.254mm (20mil)

Finished thickness: 0.8mm

Material Copper Thickness: ½(17μm)

Finished copper thickness: 1OZ (35μm)

Surface Treatment: Immersion Gold

Application: Instrument PCB, RF PCB, Radar Instrument PCB