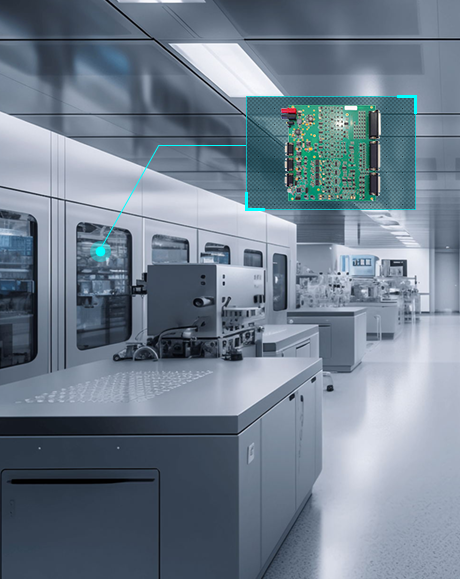

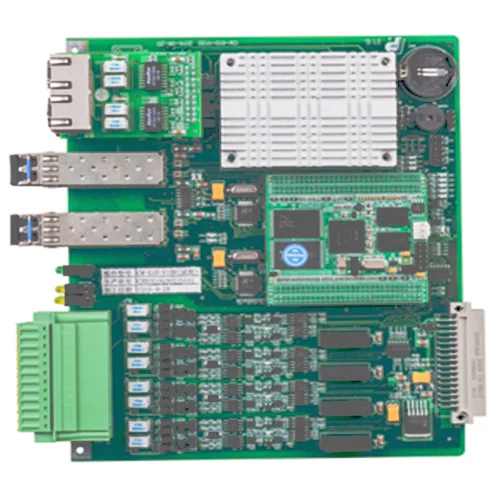

Industrial Control High Speed Data Acquisition PCB Assembly

Features

• 16-bit resolution

• 1 MS/s sample rate

• Up to 64 single-ended analog inputs

• Up to four 16-bit, 1 MS/s analog outputs

• 24 digital I/O lines

• Four 32-bit event counters

• Four timer outputs

• USB powered (no external power required)

• Includes USB cable and standoffs

• Small footprint for OEM and embedded applications Supported Operating Systems

• Windows® 11/10/8/7/Vista® XP, 32/64-bit

• Linux®

• Android™

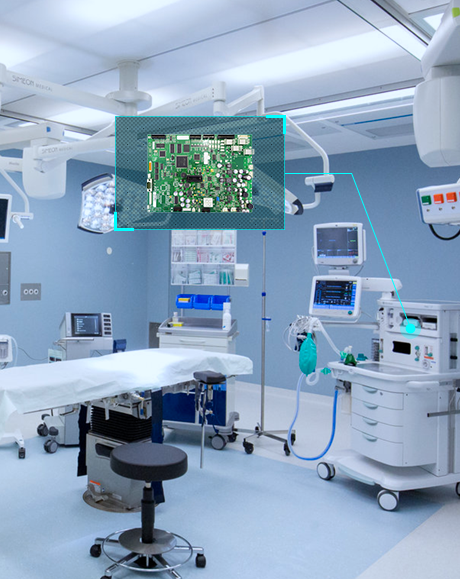

Digital image acquisition and processing system PCB assembly

technical parameter

32 I/O inputs and 64 I/O outputs

2-way optical isolation RS232

1 RS422 interface and 1 RS485 interface

48-way 16-bit synchronous 200KSPS A/D conversion

One photoelectric isolation CAN interface and one GPS timing

Built-in real-time clock, power monitoring and watchdog, etc.

Support -40~85℃ industrial wide temperature application

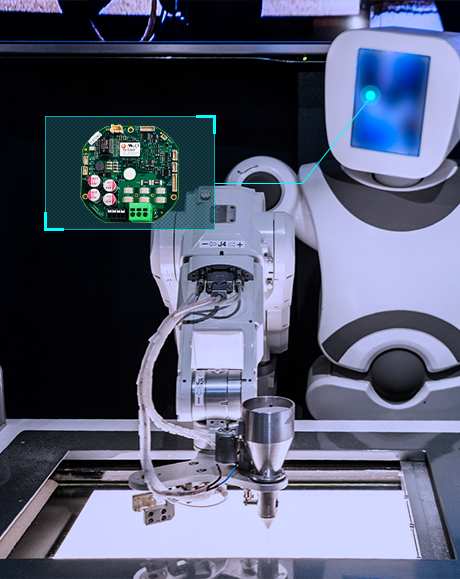

Intelligent Industrial Communication PCB Assembly

technical indicators

1. Product-oriented regulations, mainly including: frequency converter, motor protection, actuator, low-voltage switch protection

2. Redundancy solution based on PROFIBUS slave redundancy profile

3. Unified version size 45MM×70MM

4. Unified user interface UART (1M bits/s), SPI (1MHZ)

5. Working temperature: -25~+60℃

6. Power supply: 3.3V/120mA + 5V/80mA, 2 groups of regulated voltage isolation

7. PROFIBUS-DP protocol:

8. DB9 socket, isolated 2KV, RS485 output;

9. Baud rate 9.6K~12M

10. DP/V0/V1(C1+C2)

11. PROFINET-IO protocol:

12. 2×RJ45 socket (with indicator light), isolated 2KV

13. Built-in switching chip, can realize daisy chain topology connection

14. PROFINET IO RT/IRT real-time data communication

- PCB Assembly Equipment

- PCB Assembly Capability

Automatic solder paste printing machine

AOI Optical Inspection

SMT high-speed placement machine

Nitrogen reflow soldering

x-ray

Three anti-paint spraying machine

SPI Solder Paste Thickness Tester

Automatic wave soldering machine

first article inspection

| SMT capacity: 19 million points/day | ||

| Testing Equipment | X-RAY Nondestructive Tester, First Piece Tester, AOI Automatic Optical Tester, ICT Tester, BGA Rework Station | |

| Placement speed | Chip placement speed (at best conditions) 0.036 S/piece | |

| Mounted Component Specifications | Pasteable smallest package | |

| Minimum device accuracy | ||

| IC type chip accuracy | ||

| Mounted PCB Specifications | Substrate size | |

| Substrate thickness | ||

| throw rate | 1. Resistance-capacitance ratio 0.3% | |

| 2. IC type without throwing material | ||

| Board Type | POP/common board/FPC/rigid-flex board/metal substrate | |

| DIP daily production capacity | ||

| DIP plug-in production line | 50000 points/day | |

| DIP post welding production line | 20000 points/day | |

| DIP test production line | 50000pcs PCBA/day | |

| Assembly processing capability | ||

| The company has more than 10 advanced assembly production lines, dust-free and anti-static air-conditioning workshop, TP dust-free workshop, equipped with aging room, test room, functional test isolation room, advanced and perfect equipment, can carry out various product assembly, packaging, testing, Aging, etc. production. Monthly production capacity can reach 150,000 to 300,000 sets/month | ||

| PCBA processing capability | ||

| project | Mass processing capability | Small batch processing capability |

| Number of layers (max) | 2-18 | 20-30 |

| Plate type | FR-4, Ceramic Sheet, Aluminum Base Sheet PTFE, Halogen Free Sheet, High Tg Sheet | PTFE, PPO, PPE |

| Rogers,etc Teflon | E-65, ect | |

| Sheet mixing | 4 layers - 6 layers | 6th floor - 8th floor |

| biggest size | 610mm X 1100mm | / |

| Dimensional Accuracy | ±0.13mm | ±0.10mm |

| Plate thickness range | 0.2mm--6.00mm | 0.2mm--8.00mm |

| Thickness tolerance ( t≥0.8mm) | ±8% | ±5% |

| Thickness tolerance (t<0.8mm) | ±10% | ±8% |

| Media thickness | 0.076mm--6.00mm | 0.076mm--0.100mm |

| Minimum line width | 0.10mm | 0.075mm |

| Minimum spacing | 0.10mm | 0.075mm |

| Outer copper thickness | 8.75um--175um | 8.75um--280um |

| Inner layer copper thickness | 17.5um--175um | 0.15mm--0.25mm |

| Drilling hole diameter (mechanical drill) | 0.25mm--6.00mm | 0.15mm--0.25mm |

| Hole diameter (mechanical drill) | 0.20mm--6.00mm | 0.10mm--0.20mm |

| Hole Tolerance (Mechanical Drill) | 0.05mm | / |

| Hole tolerance (mechanical drill) | 0.075mm | 0.050mm |

| Laser Drilling Aperture | 0.10mm | 0.075mm |

| Plate thickness aperture ratio | 10:1 | 12:1 |

| Solder mask type | Photosensitive green, yellow, black, purple, blue, ink | / |

| Minimum Solder Mask Bridge Width | 0.10mm | 0.075mm |

| Minimum Solder Mask Isolation Ring | 0.05mm | 0.025mm |

| Plug hole diameter | 0.25mm--0.60mm | 0.60mm-0.80mm |

| Impedance tolerance | ±10% | ±5% |

| Surface treatment type | Hot air leveling, chemical nickel gold, immersion silver, electroplated nickel gold, chemical immersion tin, gold finger card board | Immersion Tin, OSP |