Certified production materials of PCBA processing plant

Many PCBA processing plants pay close attention to the quality management system and generally apply for many quality certificates for the plants. The input of this certification fee is more important to the customer's confidence in the PCBA processing plant. The following focuses on the common quality management system certification.

ISO9001:2015

Difficulty: low cost: low

This is the most common quality management system certification. Many factories generally apply for it, and the cost is relatively cheap. As an entry-level certification, its certification content is relatively basic. Many factories can basically pass the certification as long as they spend money, so the technical content of the certification is relatively low.

IATF16949

Difficulty: high cost: high

The automotive electronic access threshold certification has a relatively high technical content, and the certification content is complex. There must be strict audit standards for the factory's technology and facility strength. PCBA processing plants with ATF16949 certification have the ability to produce automotive electronic front-end circuit boards and assembly equipment.

ISO13485

Difficulty: medium cost: medium low

Medical industry quality management system certification. Focus on the technical links and quality management methods in the process of PCBA processing. The cost is moderate and the certification difficulty is medium.

UL

Difficulty: high cost: high

Ul certification is one of the most extensive certification systems in the world. It is highly recognized by developed countries such as Europe and the United States. Its certification projects are numerous and diverse, and the certification suitable for PCBA electronic component assembly business can effectively prove the hardware and software strength of the factory. The audit will be reviewed quarterly, so it is relatively open and fair. This requires PCBA processing plants to fundamentally improve the production process and have a strong quality management system to hold the certification for a long time.

PCBA processing plants may also be involved in the certification of ROHS certification, SGS certification, military industry and other subdivisions.

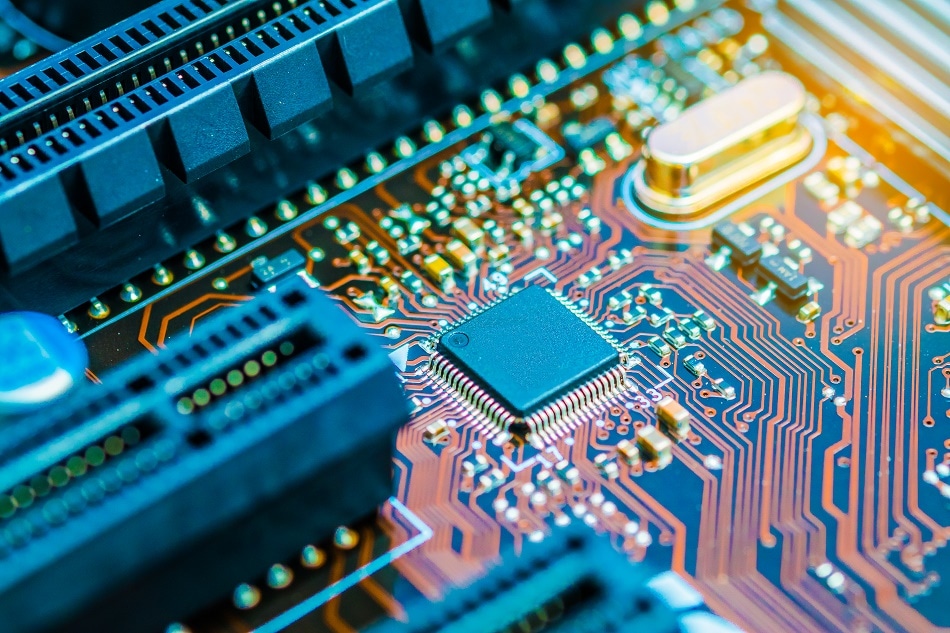

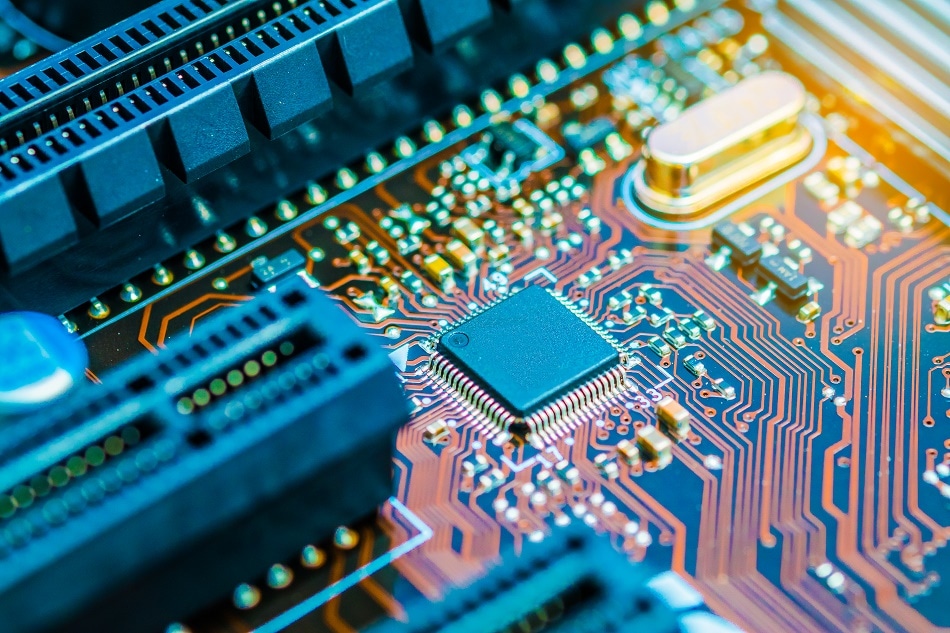

What production materials are needed for PCBA processing?

When customers provide production materials to PCBA manufacturers, they should generally prepare the following list of production materials:

PCB Gerber file (a layered file that defines the circuit, pad, silk screen and other information of each layer for manufacturing bare PCB)

Bill of Material (i.e. list of electronic components, including model, brand, description, tag number and usage information of components)

MCU program (generally refers to chip program burned into MCU, encrypted file in hex or bin format, used to drive the whole PCBA logic operation and bypass control)

Test files (define the distribution of test points, test steps and common fault diagnosis methods for functional test)

Upper computer software (generally refers to the software installed on the computer to start detection of PCBA function items)

Placement coordinate file (exported from PCB design software to define the coordinate position of each component on the PCB for SMT placement machine to read and execute)

Other design documents (such as CAD drawings, PCB schematics, special engineering process requirements, etc. that define the effect picture after welding)