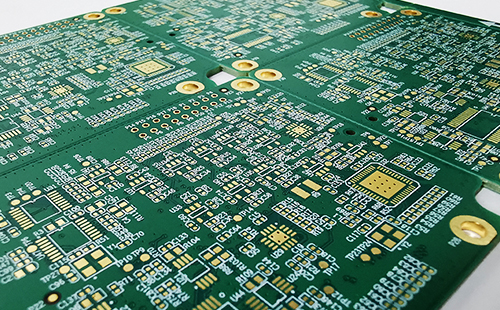

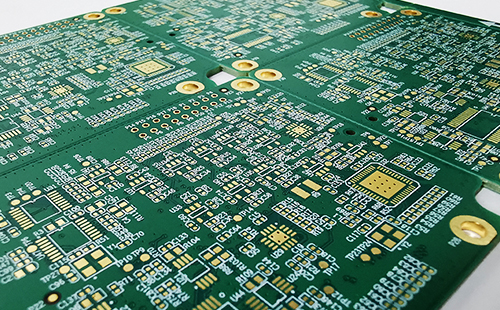

How to Select a Reliable PCB Processing Factory

At present, in the field of electronic product processing, PCB as one of the important electronic components is indispensable. At present, there are many types of PCB, such as high-frequency pcb boards, microwave PCB boards and other kinds of printed circuit boards have made a certain reputation in the market. PCB manufacturers have specific processing and manufacturing processes for various types of boards. But generally speaking, three aspects need to be considered when pcb board is processed.

1. Consider the selection of base materials

PCB substrate can be divided into organic materials and inorganic materials. Each material has its unique advantages. Therefore, dielectric property, copper foil type, base slot thickness, machinability and other properties are considered when determining the type of substrate. Among them, the thickness of the surface copper foil is the key factor affecting the performance of this PCB. Generally speaking, the thinner the thickness is, the more convenient the etching is and the higher the precision of the pattern is.

2. Consider the setting of production environment

The environment of PCB processing and manufacturing workshop is also a very important aspect, and the regulation and control of environmental temperature and humidity are crucial factors. If the ambient temperature changes too significantly, it may cause the drilling hole on the base material plate to break. If the ambient humidity is too high, nuclear energy will adversely affect the performance of the substrate with strong water absorption, specifically in terms of dielectric properties. Therefore, it is necessary to maintain appropriate environmental conditions during pcb board processing and production.

3. Consider the selection of process flow

The production of PCB is easily affected by many factors. The processing layers, punching process, surface coating treatment and other processes will affect the quality of PCB finished products. Therefore, for these process flow environments, the processing and manufacturing of pcb boards are fully considered in combination with the characteristics of the manufacturing equipment, and can be flexibly adjusted according to the different types of pcb boards and processing needs.

To sum up, the selection of base materials, the setting of production environment and the selection of process flow should be considered when pcb boards are processed. At the same time, the processing and blanking method of PCB engineering materials is also an aspect that needs to be carefully selected, which is closely related to the layout smoothness of the finished PCB.

There are many PCB processing plants on the market now. There are thousands of pieces of information about processing plants in Baidu, but it is not easy to choose a reliable PCB processing plant.

When choosing a PCB processing plant, we should clearly know what our needs are, which is the proofing verification design? Or mass production? Do I pursue speed or quality? Do I care about price or delivery time? These objective factors will affect your final choice of PCB processing plant.

However, as a reliable PCB processing plant, it must have the following:

1. Factory scale:

If you want to do a good job in PCB processing, the necessary equipment and scale are essential. The production scale and equipment perfection of a processing factory can intuitively judge the strength of this factory. It is a good choice to find a powerful PCB processing factory as a supplier.

2. Personnel quality:

A factory with strong hardware strength cannot be the only standard for a reliable PCB processing factory. It must also have professional business personnel to connect with us, understand our needs in a timely manner, and deal with various unexpected problems quickly, which is the premise for smooth long-term cooperation. After all, professional people do professional things, which is the most reliable thing.

3. Service attitude:

A good attitude is an indispensable basis and prerequisite for providing reliable products. Only a PCB processing factory with a good service attitude can calm down and make products.

4. Quality control:

Reliable processing plants will not allow problematic PCB boards to flow to the market. What they rely on here is the ability of quality control. From the quality control of raw materials, to the quality control in the production and processing process, to the quality control before the final finished products leave the factory, all are indispensable. So when we choose a processing plant, we must choose an enterprise with perfect quality control process.