How to Control PCB Board Quality in Old Brand PCB Factory

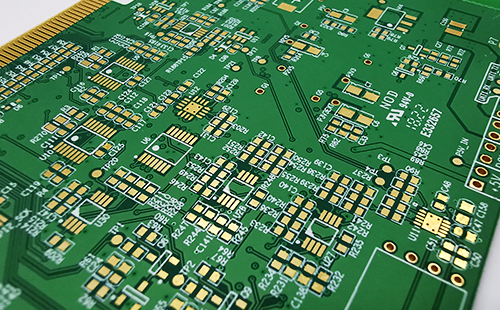

According to the number of layers, PCB can be divided into single panel, double panel, and multi-layer PCB.

First is the single panel. On the most basic PCB, parts are concentrated on one side and wires are concentrated on the other side. Because wires only appear on one side, this PCB is called single-sided circuit board. Single panel is usually simple to make and low in cost, but its disadvantage is that it cannot be applied to too complex products.

Double panel is an extension of single panel. When single-layer wiring cannot meet the needs of electronic products, double-sided panel will be used. Both sides are copper coated and wired, and the line between the two layers can be conducted through the via to form the required network connection.

Multilayer board refers to a printed board with more than three conductive graphic layers and insulating materials between them laminated at intervals, and the conductive graphics between them are interconnected as required. Multilayer circuit board (MLPCB) is the product of the development of electronic information technology in the direction of high speed, multi-function, large capacity, small volume, thin and lightweight.

PCB can be divided into soft board (FPC), hard board (PCB) and soft hard combination board (FPCB) according to characteristics.

The names of circuit boards include: ceramic circuit board, alumina ceramic circuit board, aluminum nitride ceramic circuit board, circuit board, PCB board, aluminum substrate, high-frequency board, thick copper plate, impedance board, PCB, ultra-thin circuit board, ultra-thin circuit board, printed (copper etching technology) circuit board, etc. The circuit board makes the circuit miniature and intuitive, which plays an important role in the mass production of fixed circuits and the optimization of the layout of electrical appliances. The circuit board can be called a printed circuit board or a printed circuit board, and its English name is (Printed Circuit Board) PCB (Flexible Printed Circuit board) FPC circuit board (FPC circuit board is also called flexible circuit board. Flexible circuit board is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film. It has the characteristics of high wiring density, light weight, thin thickness, and good flexibility.) and soft and hard combination plate (reechas, soft and hard combination plate) - the birth and development of FPC and PCB, The birth of the soft and hard combination board this new product. Therefore, the soft and hard combination board is a circuit board with FPC characteristics and PCB characteristics formed by combining the flexible circuit board and the hard circuit board according to relevant process requirements after pressing and other processes.

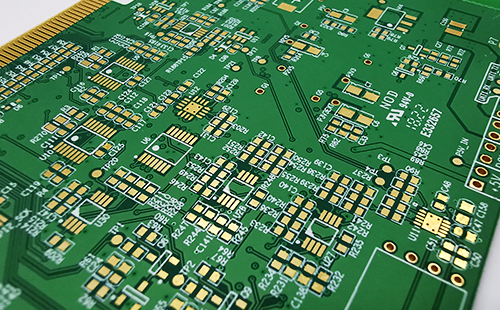

Quality is the foundation of an enterprise's survival. If quality control is not in place, the enterprise will not go far. If PCB factories want to control the quality of PCB boards, how should they control them?

If we want to control the quality of PCB boards, we must have a quality control system, which is often called ISO9001. Usually, the concept of the quality control system is real-time quality measurement and supervision. When a thing has a unified measurement standard and supervision standard, it is much easier to do well.

To control the quality of PCB boards, we should first carry out strict quality inspection on raw materials. If any defects are found, we should timely register, report and propose solutions. Only when the quality of raw materials is guaranteed, can we get high-quality PCB boards. If the quality of raw materials is not guaranteed, the PCB boards produced may also have various problems, such as blistering, delamination, cracking, warping Unequal thickness. Therefore, raw materials must be strictly inspected to provide guarantee for subsequent production.

When the quality of raw materials is guaranteed, attention should be paid to the problems that will occur in the production process. Quality inspection and patrol inspection should be carried out for each process link in the production process to ensure that each process has a work instruction to facilitate the comprehensive control of PCB quality.

After the production is completed, sampling inspection must also be carried out. Although the raw materials and production process have been inspected, there will still be defects caused by various reasons, so the whole batch of PCB boards will be sampled after the production is completed. As long as the qualification rate of the spot check is up to the standard, it is allowed to leave the factory. If the qualification rate of the spot check is not up to the standard, full inspection and maintenance will be carried out, and the quality of each PCB must be responsible for.