Requirements for BGA repair equipment

The entire repair workstation, also known as the repair system in the PCBA factory, is mainly used to repair surface mount components (SMDs) such as BGA, CSP, QFP, PLCC, SOIC, etc. of circuit boards.

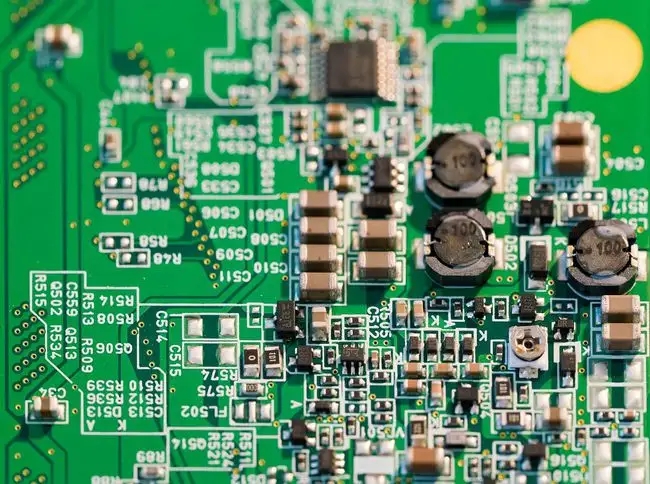

The entire repair workstation, also known as the repair system in the PCBA factory, is mainly used to repair surface mount components (SMDs) such as BGA, CSP, QFP, PLCC, SOIC, etc. of circuit boards. SMD repair workstation is mainly composed of top heater, bottom heater, optical centering system, temperature feedback system, overall framework, pcb clamp, PC and operation software. Since the welding spot of BGA is at the bottom of the device and cannot be seen, the repair system is required to be equipped with a spectroscopic vision system when re welding BGA to ensure accurate alignment when the repaired SMT is processing and mounting BGA.

BGA repair equipment requirements:

① With Vision visual image centering system;

② It is better to have temperature curve testing function;

③ With the bottom heating function, it can preheat the bottom of PCB to prevent warping;

④ When selecting hot air heating mode, select as many nozzle types as possible;

⑤ For long-term consideration, new packaged devices such as CSP, flip chip and POP can be repaired.

Different pcb manufacturers have different repair systems due to different heating sources or different hot air flow modes. Common heating sources include hot air, infrared, hot air plus infrared.

Requirements of BGA repair equipment and characteristics of the system

1. Hot air repair system

Also known as hot air repair workstation, it is the most commonly used repair system. Hot air repair workstation is mainly composed of host controller system, hot air heating system, heating system at the bottom of workbench, workbench holding PCB, centering beam splitter system, high-resolution camera, color monitor and other components. The temperature curve can be monitored and adjusted at any time during repair.

The main features of the hot air repair system: it is not easy to damage the SMD and the substrate or the surrounding components; Different nozzles are required for repairing different SMDs; During PCB design, 3-5mm repair space shall be reserved.

2. Infrared heating repair system

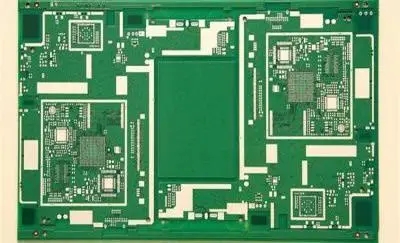

The infrared heating repair system uses infrared heating, and the centering uses a light splitting (red and white) system. The visual centering and heating are separated, that is, the visual centering and mounting devices are first performed, and then the workbench is moved to the lower part of the heater for welding. If the endoscope inspection system is configured, two real-time images of the settlement of the welding ball during BGA, CSP welding can be observed.

The main features of the infrared heating repair system are: no nozzle is required for repair, and small repair space should be considered for design; It is more suitable for repairing high-density pcb assembly boards (such as mobile phone circuit boards), as well as SMD devices such as BGA and through-hole components.

3. Hot air infrared repair system

The top of the hot air infrared repair system is heated by hot air, and the bottom is preheated by infrared. The hot air infrared repair system combines the advantages of hot air and infrared repair systems; Rapid heating; The bottom is fully preheated to realize the whole plate heating and uniform temperature; It is more suitable for the repair of large plates and lead-free products.

The above are the requirements and system characteristics of BGA repair equipment explained by PCBA factory.