A Remedy for Circuit Board Short Circuit

In general, PCB circuit board is short circuited. The remedy is to cut the short circuited area with a knife, and then apply a layer of insulating solder mask. When there is a short circuit at a fixed place in batch, it is very troublesome to cut it manually, time-consuming and laborious, and the quality is also very insecure. When the circuit board is short circuited at a fixed place after being soldered, it is a very troublesome problem. When this problem occurs, it is often a whole batch of scrapped, and valuable components are disassembled to reduce losses. But the cost is still amazing, and many circuit board manufacturers can't afford it. Most of the time, customers and circuit board manufacturers broke up in discord, and some even resorted to legal means. The following is a simple and easy way to help you. I hope it can be helped by using the CNC engraving machine to install the engraving cutter on the CNC edge milling machine of the circuit board, complete the path milling information, and use the engraving machine to carve the correct circuit at the fixed short circuit location.

Step 1: Check and analyze the situation of the problem board to prepare for the future. The circuit board with components welded is generally uneven, and the fixed short circuit area can be presented horizontally and widely, which is convenient for the cutter of the milling machine to work. In order to make the circuit board with components flat on the platform of the edge milling machine, it is sometimes necessary to make a fixture, which is equipped with some locating pins according to the situation of the board. The corresponding area of the raised components should be hollowed out on the fixture, so that the circuit board can be flat and fixed on the platform of the edge milling machine.

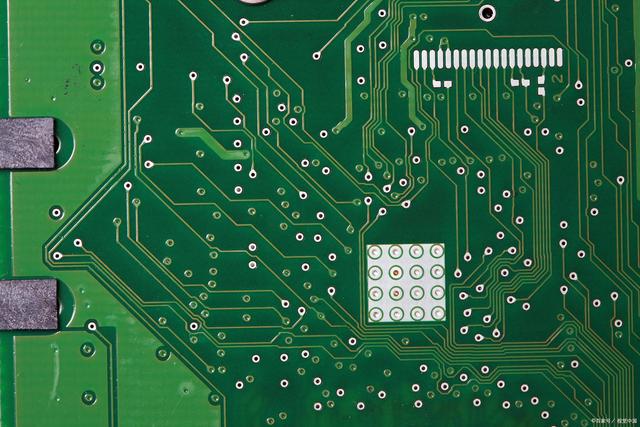

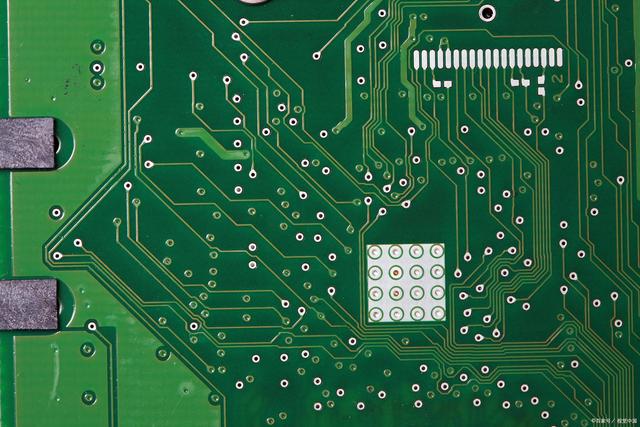

The precision of the CNC edge milling machine in the circuit board factory is within 0.1mm

Step 2: The engineer makes the path that the carving knife needs to cut according to the short circuit. The engineering personnel of the general circuit board factory have this kind of skill.

Step 3: The operator of the edge milling machine adjusts the depth of the carving knife. Since the edge of the carving knife is in a V-shaped line, the deeper the knife is, the wider the cutting path is on the circuit board. Some short circuited circuit boards are very precise. The depth of the cutting knife should not be too deep. However, when the knife tip is shallow, it often cannot touch the circuit board, or the short circuited copper foil is not completely cut when it is touched. Therefore, we must ask an experienced milling machine master to debug. This is very important and directly affects the cutting quality.

Step 4: Test the electrical performance of the processed circuit board. The copper foil of the circuit board that has been cut may be turned up or not completely cut in place. It needs to be checked and handled again.

Step 5: Apply a layer of solder mask ink on the cut area and bake for curing.

Although the above method is a last resort, the author has tried it well, and the cutting accuracy can reach the minimum line width of 0.4 mm. If the precision of the edge milling machine is enough, the problem board with the precision of 0.3mm line width and line distance can be handled.