The production, quality and technology departments of PCBA plant are not "separated by three powers"

Circuit board manufacturers, circuit board designers and PCBA manufacturers explain that the production, quality and technology departments are not "separation of powers"

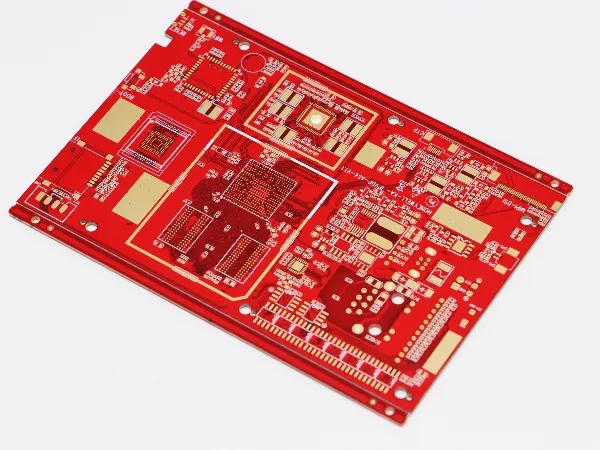

PCBA processing is to connect various electronic components on PCB board through surface mount (SMT), plug-in (DIP) and other electronic assemblies. PCBA process flow mainly includes SMT, AOI, DIP, FCT testing and other processes. Due to the size difference of electronic components, there will be different processes and requirements in assembly and insertion. The assembly density of PCBA is relatively high, and the small size and light weight of electronic products also have certain changes and requirements in mounting. The reliability, seismic resistance and excellent weldability of the product have high requirements on the hardware and software facilities for PCBA processing

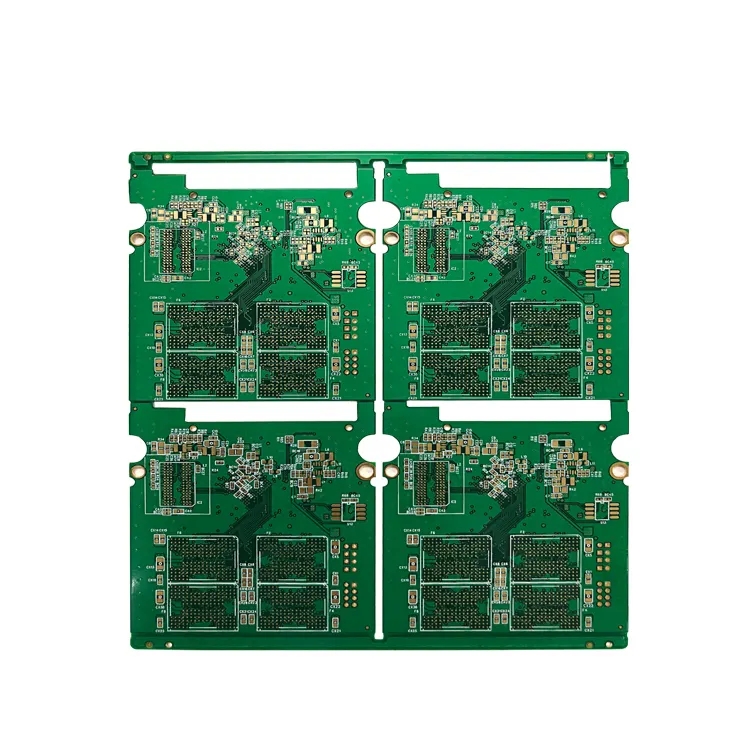

At present, the electronic processing factory provides a processing service - PCBA one-stop service. The all-in-one service of PCBA requires the coordination of production, quality and technical departments to deliver products that satisfy customers. However, there will be many problems in the actual production process. Whether it is material preparation, production process and schedule, or quality inspection, many pcb factories generally find that different departments are shifting responsibilities between each other. If all departments throw hot potato around, it will affect the actual production and production quality. In fact, as long as the production, quality and technology departments perform their own duties, cooperate with each other and check each other.

In fact, as long as the production, quality and technology departments perform their own duties, cooperate with each other and check each other, they can effectively improve production efficiency. In the factory, production is the core department. Whether the electronic processing factory can deliver the products on time and ensure the product quality is largely decided by the production department. The head of the production department needs to strictly control the production process and process, and at the same time, go to other departments, such as the quality and technology department, to coordinate and communicate to ensure the circulation of production information. At the same time, the PCBA production department also needs to receive feedback from the quality department and the technical department on the quality control and suggestions of PCBA production, so as to improve the production quality. The quality department needs to inspect the finished products from the PCBA production department for process inspection and quality inspection. The quality department is an important part of the PCBA factory. All PCBA production must pass QC inspection. The quality department is the core to ensure the yield of PCBA finished products. However, the quality department is dependent on production to survive. Therefore, if the departments try to shift the blame when encountering problems, it will actually hurt their own interests. At the same time, the technical department solved technical problems such as PCBA board improvement or program burning.

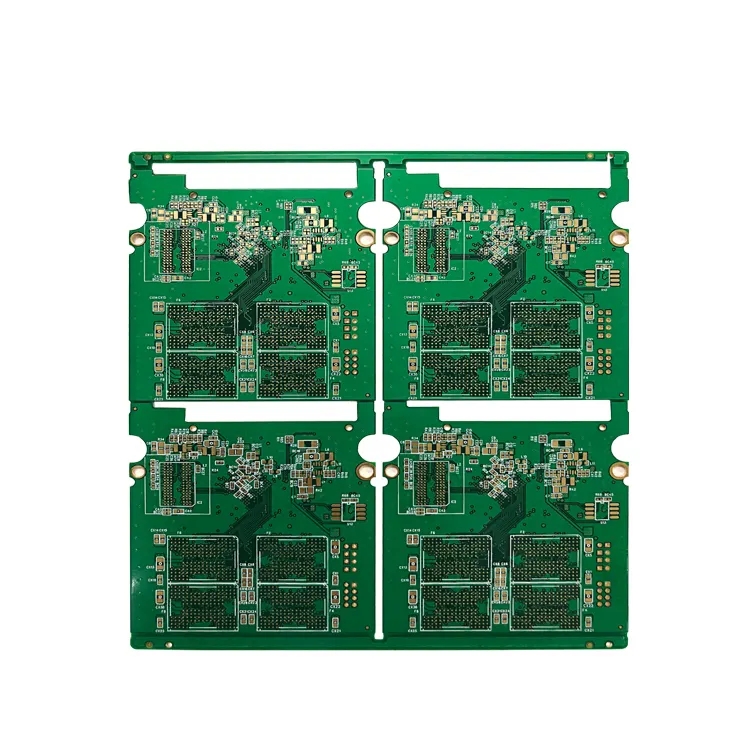

From this, we can know that the production, quality and technology departments of PCBA plant are interdependent. Only when departments cooperate with each other can we achieve win-win results.