PCB Factory: What is ICT? What are the advantages and disadvantages?

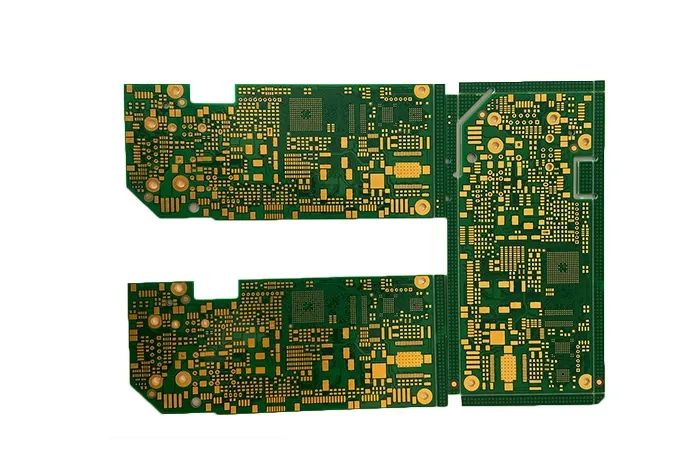

1、 What is ICT? ICT is mainly used for the electrical test of printed circuit board assembly (PCBA). It can basically be thought of as an advanced "multimeter" or [LCR meter]. It can detect the electrical properties of all parts on the circuit board and whether there is an open/short circuit problem in the welding through the pin point without removing the electronic parts from the circuit board. ICT works by using a Bed of Nails to connect the test points arranged in advance on the circuit board.

1、 What is ICT?

ICT is mainly used for the electrical test of printed circuit board assembly (PCBA). It can basically be thought of as an advanced "multimeter" or [LCR meter]. It can detect the electrical properties of all parts on the circuit board and whether there is an open/short circuit problem in the welding through the pin point without removing the electronic parts from the circuit board.

The operation principle of ICT is to use the Bed of Nails to connect the test points arranged in advance on the circuit board to achieve the purpose of testing individual parts or Nets. Just like taking the resistance on both sides of a three-way ammeter, you need to place the truth detector on both ends of the resistance. ICT can only be measured by placing a pin point on the test point extended from the contact pin of all parts. Sometimes you can also imagine a string or a local block circuit as a part, and then measure its equivalent resistance, capacitance and voltage. This can reduce the number of test points. Generally, we call this measurement Nets test.

ICT automatic online tester

In general, the main defects of circuit board assembly mostly focus on welding open circuit, short circuit, offset, missing parts, wrong parts, etc., accounting for more than 90% of the defects. Except for some defects, the rest can be picked out 100% of the defective products through ICT testing. The "offset" may not be detected by ICT electrical measurement, because as long as the part leg is still welded to the location, it cannot be detected if there is no abnormality in the electrical test. In fact, such defects are not bad and need to be further clarified. They are not necessarily bad. In addition, the contact instability caused by cold/false soldering may not be 100% picked out by ICT, which should be the most troublesome place, because ICT detects the circuit through electrical testing. If the solder joint is still in contact during testing, it cannot be detected.

Therefore, ICT can basically perform the following functions or parts:

1. open circuit, short circuit, detection of wrong parts, missing parts, erection of monument, bridging, reverse polarity.

2. It can measure resistance, capacitor, inductor, transistor, diode, zener diode, triode optocoupler, relay, field effect transistor test (FET), IC, connector and other parts.

3. Through the TestJet, it is possible to measure the short circuit of the IC part with the connector or solder pin outside the PIN bank without pin points.

4. DC/AC voltage measurement and frequency measurement.

5. Electrical function test. Low order programs (such as BIOS) can be executed for self detection.

6. [Boundary scan/JTAG] can be used to test the function of active parts.

7. It can automatically download software or operating system to the memory of the circuit board.

2、 Advantages of ICT test circuit board

1. The test speed is fast and the time is short. PCBA can perform L/C/R/D test without power on, which can effectively reduce the waiting time for test power on, and also reduce the circuit board burning accident caused by short circuit. A piece of circuit board with 300 parts assembled can be tested in 3-5 seconds.

2. Excellent retestability. Controlled by computer program, accurate measurement greatly reduces the risk of miscalculation and missed measurement, and reduces the trouble of the production line. (If there is a problem of poor contact at the test point, it may cause misjudgment)

3. On site technology dependence is low. Because computer control is used almost all the time, which greatly reduces the time and errors of manual operation. General operators can easily operate the equipment and replace the test fixture by themselves as long as they have a little training. (The test procedure must be maintained by a professional technician or engineer).

4. The cost of product repair has been greatly reduced. General operators can be responsible for product maintenance, effectively reducing personnel costs. ICT can tell the part or the Net that there is a problem through a computer program, which greatly reduces the speed of technicians to re measure defects and remove pests.

5. Improve the product yield (through put). Through fast testing, the problem can be fed back to the front SMT immediately to reduce the defective rate of production, reduce the stock of materials and the accumulation of defective products, and reduce the cost and improve the competitiveness.

6. Improve product quality. As long as there are enough test points, ICT can measure all lines and parts on the circuit board, and the parts on the bypass lines can be measured, which can improve product quality, reduce customer complaints, and even improve performance.

3、 Disadvantages of ICT circuit test:

1. ICT equipment and jigs are generally very expensive, especially pneumatic steel jigs, which sometimes cost NT $40-500000, and are more suitable for mass production.

2. When using ICT test, additional test points need to be designed on the circuit board for connection of the needle bed. The utilization rate of circuit board wiring is reduced.

3. The test points sometimes have different poor contact problems due to different surface treatment methods. For example, the OSP board needs to print solder paste on the test point to reach the purpose that the conductor can contact, but the solder paste with flux is easy to form a protective film.