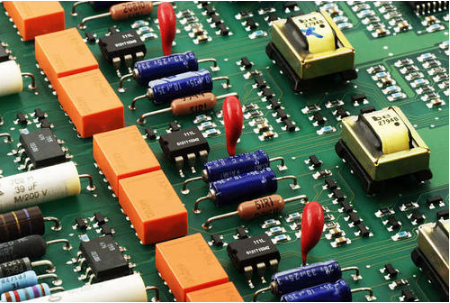

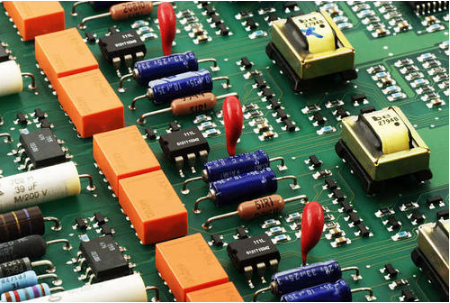

SMT is the most popular production process in the PCB assembly industry, which meets the requirements of lightweight and batch production of mobile phones and computers. The PCBA assembled from SMT has a relatively high density and light weight, and has completed mass production of automation technology. The feature is that spot welding is on the same plane as the upper plate, and the welding process is reflow welding.

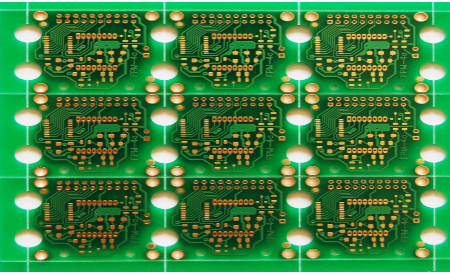

THT cannot be replaced in the automotive electronics industry in the short term, but it has been gradually replaced in the consumer electronics industry. The distance between electronic components on PCBA made by THT processing technology is far, and the total board area is also large. The feature is that components and spot welding are respectively located on both sides of the board.

Solder paste packaging and printing: the scraper scrapes the solder paste in, hollows out and carves it into a mesh plate of the desired shape for welding, and then moves the solder paste down to accurately match the parts that must be welded. The cost of screen board varies from several thousand yuan, but the normal maintenance cost of steel tin slag and scratches on the screen cannot be ignored.

Note: The solder paste should be heated before application. No equipment heating is required because too fast temperature will cause the solder paste to crack.

SMT patch

Reflow soldering is a special PCB process flow in the SMT processing process. In the reflow soldering process, the plastic circulation system vapor is introduced to ensure a high temperature vapor atmosphere. The solder paste distributed on the welding layer is melted again and finally condensed by the cooling air.

Reflow soldering only has one single and double side soldering. If it is SMT on both sides, it must be reflow soldering for the second time. Since the melting temperature of solder paste after drying exceeds the reflow temperature, the original SMT on the back is not easy to fall off.

Wave soldering is to make the welding surface of the software board immediately touch the high temperature liquid tin to achieve the welding target. The high temperature liquid tin maintains a slope, and the liquid tin is produced by a unique device with similar wavy lines. Therefore, it is called "wave soldering".

For some requirements that both SMT and THT are necessary, the mixed application of reflow soldering and wave soldering is unavoidable. It should be noted that wave soldering must be carried out after reflow soldering. First, because the reflow welder is covered with hot gas, the solder paste will be melted again after going through wave soldering and then going into the reflow welder. Second, most electronic components assembled in the THT processing process contain feet, If the conveyor belt is put into reflow soldering again, it will cause uneven placement.

For some requirements that both SMT and THT are necessary, the mixed application of reflow soldering and wave soldering is unavoidable. It should be noted that wave soldering must be carried out after reflow soldering. First, because the reflow welder is covered with hot gas, the solder paste will be melted again after going through wave soldering and then going into the reflow welder. Second, most PCB components assembled in the THT processing process contain feet, If the conveyor belt is put into reflow soldering again, it will cause uneven placement.