In the manufacturing process of industrial control medical double-sided PCB circuit board, in order to avoid the electromagnetic radiation generated when high-frequency signals pass through the printed wire, the following points should also be noted when wiring the industrial control double-sided PCB circuit board:

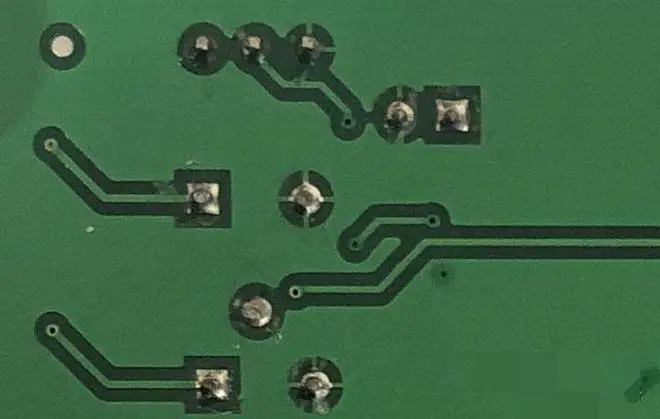

1. Try to reduce the discontinuity of the wire on the industrial control medical double-sided PCB circuit board, for example, the wire width should not change suddenly, the corner of the wire should be greater than 90 degrees, and circular wiring is prohibited.

2. The clock signal lead is most likely to generate electromagnetic radiation interference. When wiring the industrial control medical double-sided PCB circuit board, it should be close to the ground circuit, and the driver should be close to the connector.

3. The bus driver shall be close to the bus to be driven. For those leads leaving the printed circuit board, the driver should be close to the connector.

4. A signal ground wire shall be clamped between every two signal wires for the wiring of data bus of industrial control medical double-sided PCB circuit board. It is better to place the ground loop close to the least important address lead, because the latter often carries high-frequency current.

5. When arranging high-speed, medium speed and low-speed logic circuits on the printed board, the components shall be arranged

6. The industrial control medical double-sided PCB circuit board can suppress reflection interference. In order to suppress the reflected interference at the terminals of printed lines, except for special needs, the length of printed lines should be shortened as much as possible and slow speed circuits should be used. If necessary, terminal matching can be added, that is, a matching resistor with the same resistance value can be added at the end of the transmission line to the ground and the power supply. According to experience, for general fast TTL circuits, terminal matching measures should be taken when the line length of industrial control medical double-sided PCB circuit board is more than 10cm. The resistance value of the matching resistance shall be determined according to the maximum value of the output drive current and the absorption current of the integrated circuit.

Differences between medical PCB production and ordinary PCB

The pace of social development is fast. People pay more and more attention to health, the medical devices put forward higher requirements for the performance of pcb materials. What are the technical requirements for the reliability, high frequency, high speed and high conductivity of pcb in medical treatment.

The medical PCB has become one of the most complex and challenging in the industry. Many people in the industry say that medical PCBs are just like ordinary PCBs. Is there anything different? The answer is yes.

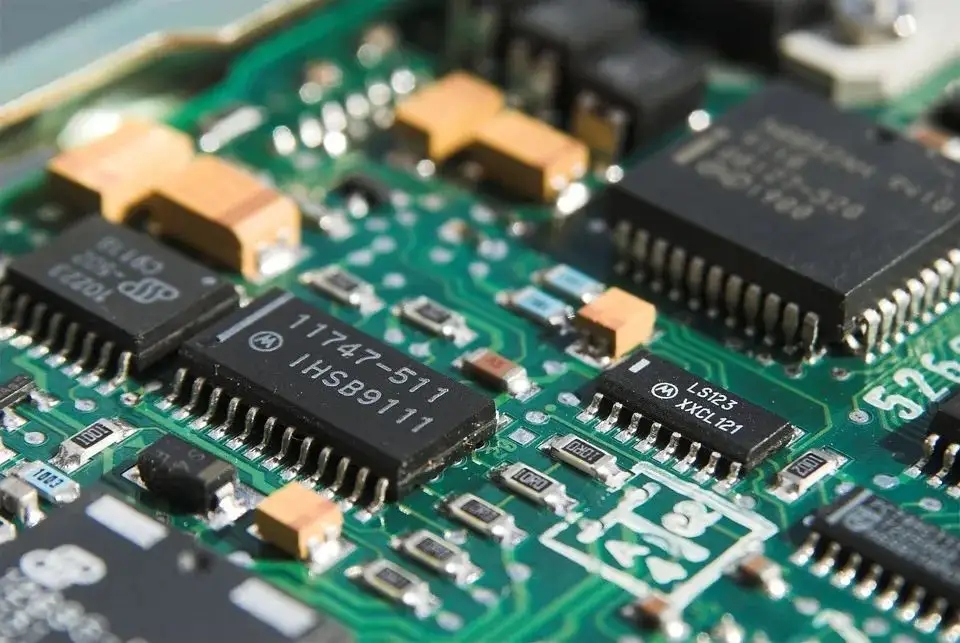

Medical pcb circuit board

To sum up:

Medical PCB circuit board has the following aspects

1) "Safety" and "reliability": are the core issues of PCB in the medical industry. Refer to IPC-3 for life support products or high-end products

For non life support or low-end products, please refer to IPC-2. Large medical terminals establish their independent and standardized enterprise standards to strictly control the reliability of products. So this is very important.

2) Long service life: the warranty period of general products is more than 5 years, and that of large medical equipment is at least 10 years

The use of is long. There are some differences between pcb and ordinary pcb.

3) Large hierarchy span: from consumer medical products that meet the routine requirements, to medium and high-end medical products that meet the requirements of high reliability and stability, to small portable products that meet the requirements of high density and high integration, and wearable medical products that meet the requirements of intelligence and multi-function.

4) Product conservatism: the application of new medical technologies and new products to the market is slow, and the validation tests of new products are repeated, often requiring comprehensive evaluation.

5) Traceability: the product is required to have strict process records and product traceability, and some large medical terminals are required to ensure

Traceability of 10-year PCB processing records.

6) The process treatment and fire rating requirements of medical pcb boards are different. The common pcb process is different in handling tin spraying and cleaning boards. On the premise of taking process measures and ensuring quality safety, it can be used for repair products with discretion.

7) The demand for general medical PCBs is small, and PCB process requirements are large, such as back drilling, multiple pressing, mixed pressing, high-precision, special impedance, thick copper, thick gold, embedded copper blocks, etc. The price focus will be very low, which is different from the common pcb board.

Among all medical PCB boards, FR-4 is the most widely used. For medical PCB design, there will be differences in the selection of FR-4 boards according to the product positioning and the control of raw material prices. For large hospitals, reliable pcb manufacturers should be selected.