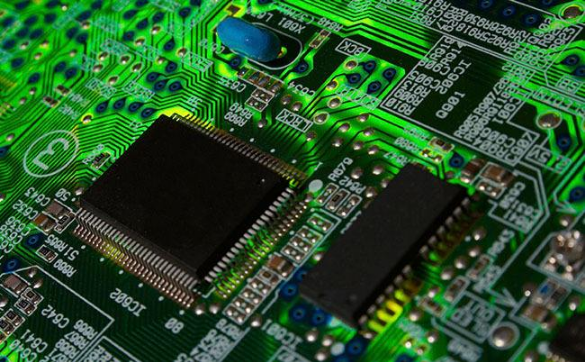

What are the routine inspection methods for printed circuit boards

The appearance of the printed board is visual inspection, which can be done with a magnifying glass or projection magnifier. Each board shall be visually inspected under necessary lighting conditions. In the production process of the circuit board factory (Shenzhen circuit board), some use automatic optical inspection (AOI) equipment to check the defects of the board surface. If necessary, micro sectioning can be adopted to observe the local state under the microscope.

Shenzhen Circuit Board Factory tells you the routine inspection methods for printed circuit boards

(1) First, the circuit board factory conducts dimensional inspection on the circuit board during production

In Shenzhen Circuit Board Factory or other circuit board factories, dimension inspection includes mechanical measurement and instrument measurement, generally sampling inspection. For mechanical measurement, measuring tools suitable for measuring range and reading accuracy shall be used. For f, vernier caliper, micrometer card, plug gauge and precision gauge shall be used_ Long meter, etc. Instrument Thickness gauge and reading microscope, etc. For the special thickness gauge for precious metal forging layer, the copper thickness and inner layer structure size can be measured by a reading microscope through microsection. Microsectioning refers to sample preparation for metallographic examination of an object, including section cutting, potting, grinding, polishing, etching and dyeing.

(2) Mechanical inspection

According to the experience of Shenzhen Circuit Board Factory, I can use a peel tester and a tensile tester to measure the peel strength of the conductor on the printed board sample and the pull off strength of the connecting plate. Our PCB factory is very strict in the inspection control.

(3) Electrical performance inspection

The circuit integrity of printed boards refers to the open circuit and short circuit inspection. A circuit detector usually checks every board. In this way, we can ensure the product quality of our circuit board factory (Shenzhen circuit board), and use appropriate test instruments for insulation resistance, withstand voltage and impedance, such as megger, withstand voltage meter and impedance tester. These are sampling inspections only.

Shenzhen Circuit Board Factory tells you the routine inspection methods for printed circuit boards

(4) Environmental inspection and other inspections

The same is true for environmental inspection, which is carried out according to the specified cycle or batch. Shenzhen Circuit Board Factory has strictly controlled the environment in recent years. The equipment for inspection includes electric oven, humidity oven, high temperature oven and low temperature oven, soldering bath, hot water bath and drying oven.

Our Shenzhen Circuit Board Factory has many years of experience. The routine inspection of printed circuit boards is generally the above four points. The operation of the circuit board factory and the quality of its products are inseparable from the quality inspection. Therefore, to be a high-quality circuit board manufacturer, we must ensure the quality of our products.

The PCB manufacturers, PCB designers and PCBA manufacturers will explain to you the conventional inspection methods of PCB.