Effective communication between circuit board manufacturer and EMS service provider

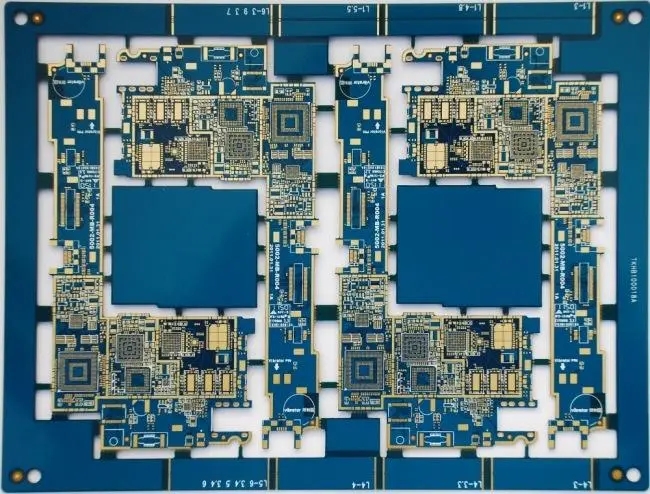

Circuit board manufacturers, circuit board designers and PCBA manufacturers explain effective communication with EMS service providers

In the past few decades, OEM companies have outsourced production to EMS service providers to manufacture various products, ranging from PCBA to whole letter boxes and cable assemblies. Effective communication is the key to successful realization from concept to product. For OEM companies that want to form a good working relationship with EMS service providers, the following steps should be followed to ensure successful product construction. This is particularly important when working with suppliers around the world. This article will focus on effective communication methods between OEM and EMS suppliers, and discuss some very simple methods to avoid some problems related to outsourcing services.

Statement of Work (SOW)

SOW (Statement of Work) is a very common document in the military and aerospace fields of the electronic manufacturing industry. The SOW clearly states the customer's expectations of EMS service providers. Details include: technical specifications to be followed, ITAR restrictions, processes, version levels, quality descriptions, deliverables, reporting requirements, FAI (Fail As Is) requirements, and other special instructions not found in any other document. In the field of commercial products in the manufacturing industry, SOW usually does not exist. EMS service providers need to put together a large number of e-mail instructions and instructions to form SOW. Some information will inevitably be missed or not communicated to the workshop. In essence, the SOW defines the rules for participation.

In addition to the detailed SOW, the complete input file package is the most important part of the quotation and production process, and should contain as much information as possible. This will allow EMS service providers to provide accurate quotes and identify issues that may require attention.

input file

Organization is the key to a good input package. The concise input file package shall include but not be limited to the following items:

• BOM (Excel format)

• Output data (IPC-2581, ODB++, Gerber, IPC-D-356 netlist, X-Y data, etc.)

• Manufacturing drawings (PDF or DXF)

• Assembly drawing (PDF or DXF)

• Test requirements

• Project description

BOM

The bill of materials shall include item number, quantity, reference code, component manufacturer, manufacturer's part number and component or packaging description. Excel format is the preferred format, which can be easily imported into many different systems.

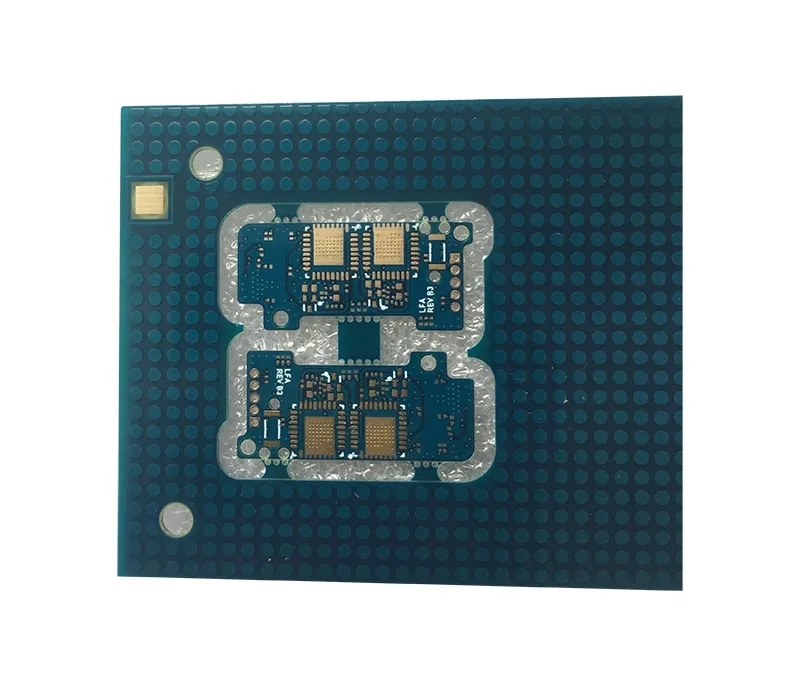

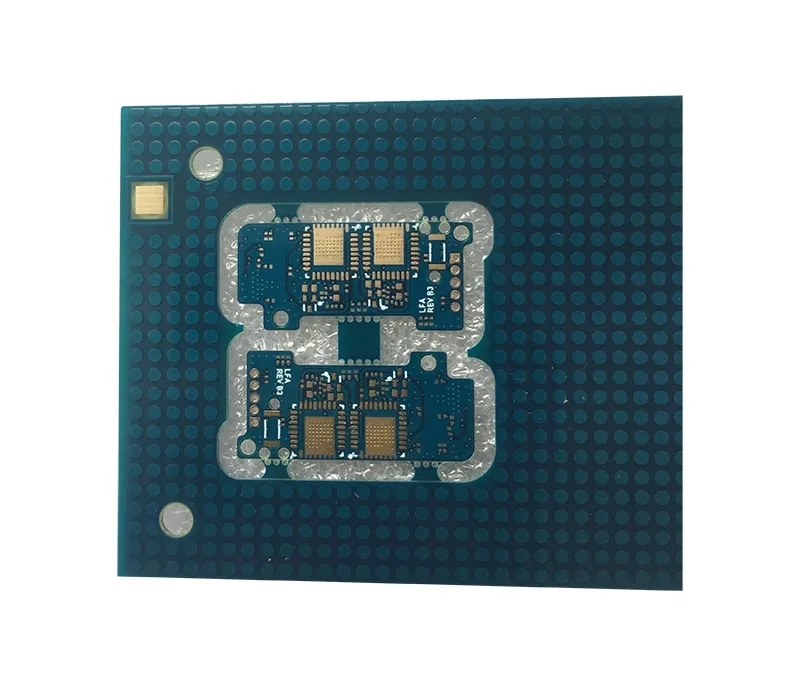

output data

Although there are several options, Gerber data seems to be the industry standard that every company tends to adopt. The problem with Gerber data is that it does not contain any helpful intelligence information. The outputs that can provide intelligent data include ODB++and IPC-2581.

Manufacturing and assembly drawings

The key to successful manufacturing is documentation. Including notes, surface coatings, materials, production instructions, appearance details, labels and marking formats.

Test requirements

The test requirements can be as simple as stating whether flying needle or needle bed/ICT test is required, or providing a complete set of instructions for functional test. At the same time, specify whether to provide the service provider with functional test equipment or test fixture.

Item Notes

Although notes should be included in the manufacturing and assembly drawings, some people prefer to provide additional notes that cannot be found on the drawings. Notes are an important part of conveying specific assembly details, such as solder/flux type, label format, serial number, cleaning instructions, etc.

Other considerations

technical specifications

I am a super fan of industry norms. IPC and SMTA provide a large amount of professional technical information from PCB layout to bare board manufacturing to final PCB assembly. An experienced layout expert will study and understand the best method to complete the design, so that the manufacturer and EMS service provider can complete the subsequent process after the design stage. Unfortunately, many engineers and designers do not understand the details and processes involved in making designs from CAD systems to finished products. A really good designer must know some basic knowledge of chemistry, physics, thermodynamics, materials, etc. Any competitive EMS company can produce products that meet industry standards.

Avoid changes during the assembly cycle

Immediate change requires time and cost, and sometimes causes many unnecessary confusion. Plan ahead to avoid changing components or circuits during the assembly phase. Under the current supply chain constraints, ensure that the materials selected for the project are easy to obtain, or there is a list of alternative part numbers for selection. The final change before the project starts will cause the project plan to be delayed and increase the costs related to the project. This means that the EMS service provider's normal production process is interrupted, and other project plans must be reorganized to meet the new manufacturing requirements.

Pre production meeting

If there is enough time, it is a good idea to hold a pre production meeting. These meetings will allow all relevant personnel to express any comments or questions, review documents, and discuss the overall scope of the project. Remote team meetings can be easily scheduled through Zoom, Teams, or other platforms of your choice.

Put everything on record

EMS service providers undertake hundreds of projects every year, so any form of oral instructions or instructions to sales personnel or project managers can be devastating. It is better to follow up the communication with the EMS service provider through email or other types of written documents or communications.

conclusion

A detailed set of instructions and organized document package from beginning to end can save time, effort and cost, and eliminate rework and omission at each stage of the product development cycle. The only way to avoid unnecessary obstacles is to organize the input package in a way that is conducive to getting accurate results every time. The EMS service provider will thank you for the extra time you have invested in providing the perfect package.

Circuit board manufacturers, circuit board designers and PCBA manufacturers explain the effective communication with EMS service providers.