High processing cost of automobile soft and hard combination plate patch

Circuit board manufacturers, circuit board designers and PCBA manufacturers explain to you where the cost is high in the processing of automobile soft and hard composite board pastes

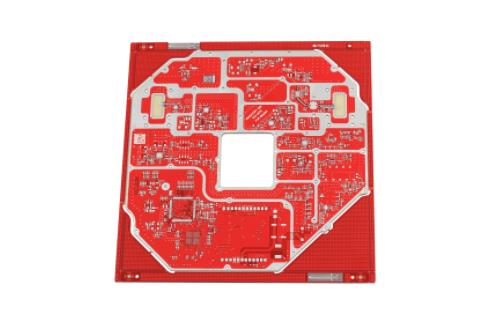

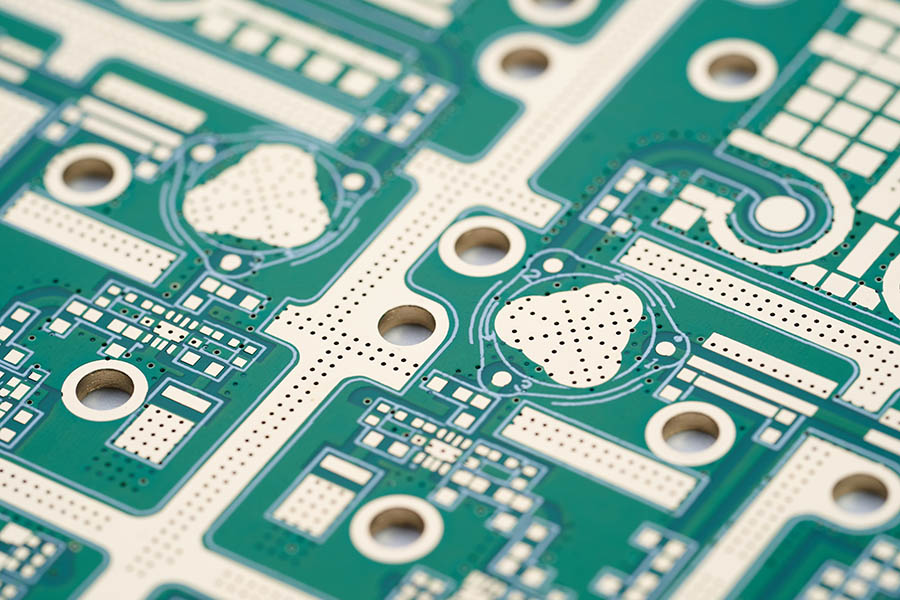

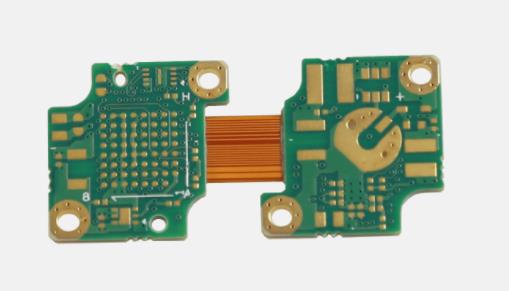

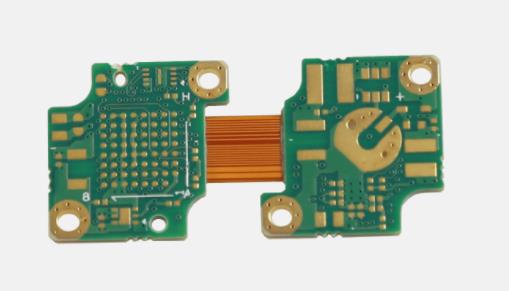

The birth and development of FPC and PCB gave birth to the new product of soft and hard combination board. Therefore, the soft and hard combination board is a circuit board with FPC characteristics and PCB characteristics formed by combining the flexible circuit board and the hard circuit board according to relevant process requirements after pressing and other processes.

To understand where the cost is high in the processing of automobile soft and hard bonding plate pastes, we need to break down the whole process of labor and material contracting for automobile soft and hard bonding plate pastes. Automobile soft and hard bonding plate pastes mean PCB assembly, so they must include two major parts: circuit board light plate and component welding (SMT surface mounting/DIP plug-in post welding). At present, the price of light plate in the market is between 350 and 550, The prices of components are basically open and transparent in major shopping malls, which can be compared and referred to.

Since there is no possibility to increase the price of the main automobile soft and hard bonding plates and components, the cost is reflected in the assembly process. The main costs of this link are as follows:

1. Auxiliary materials: solder paste, tin bar, flux, UV glue, furnace fixture

The quality of solder paste and solder rod is the most important auxiliary material in the whole processing process. Generally, the price of domestic solder paste is 180~260yuan/bottle, and that of imported solder paste may be 320~480/bottle. Therefore, the price of imported solder paste is much higher for the same welding area, but the quality and quantity of welding are very different.

2. SMT chip processing

According to the different points and packages, there will be some price differences in the processing of automobile soft and hard bonding plate pastes. It is a consensus in the industry that large quantity and high price are better. The larger the package size of components, the easier it is to mount them, and the corresponding poor quality will be reduced. Therefore, there is more room for price communication.

3. Welding time cost after DIP plug-in

As the plug-in material link involves irregular parts and material forming, it requires a lot of manual participation, because there is no capacity reference for machinery and equipment, this link is the most difficult to control the cost. At the same time, the labor cost remains high, and the cost of this link is generally high.

4. Assembly test: test fixture, test equipment, test man hour

At present, according to the test difficulty, the test fixture for automobile soft and hard bonding plates ranges from tens to hundreds of yuan, but in addition, the test of communication equipment also requires the assistance of optical fiber, ICT and other test equipment, and the corresponding labor and equipment losses need to be taken into account, but not very high.

The manufacturers of circuit board manufacturing, circuit board design and PCBA processing will explain to you where the cost is high in the processing of automobile soft and hard composite board pastes.