As the production and manufacturing process of PCB involves a variety of physical or chemical processes, the production process is more complex, will produce waste water, waste gas, solid waste and other pollutants, will have a certain impact on the environment. In order to control the increasingly serious pollution problem, China has made relevant regulations on the allowable discharge and emission concentration of waste gas, waste water and waste residue from industrial pollution sources (referred to as "three wastes"), among which the three wastes in the production process of printed circuit board put forward specific standard requirements.

The Ministry of Environmental Protection has printed and sent to 14 departments, including the National Development and Reform Commission, the Ministry of Finance, the Ministry of Commerce and the People's Bank, the Comprehensive List of Environmental Protection (2017 edition). Item 876 of the Comprehensive list lists "printed circuit board manufacturing (3972)" as "products with high pollution and high environmental risks".

After careful study of relevant documents and discussion by China Electronic Circuit Industry Association (CPCA), we believe that "printed circuit board manufacturing (3972)" should not be included in this comprehensive directory!

CPCA believes that printed circuit board is an indispensable part of the electronic information industry, which is the key industry encouraged by the state. So far, more than 100 related enterprises have been listed, and now it is actively pushing forward to be among the world's advanced.

In its request report, CPCA stated:

"The six pollutants of 'heavy metal mercury, cadmium, hexavalent chromium, total chromium, lead and arsenic' in industrial wastewater are items that need to be strictly controlled. Although the amount of emissions in industrial wastewater is very small, the harm impact is great, so they should be classified as' high pollution and high environmental risk '. However, there are no such six pollutants in our PCB industry now.

Printed circuit board production process, the main pollution is copper and COD, its emissions in the national total industrial wastewater discharge insignificant. And the pollutants produced have mature process technology for treatment, in terms of treatment technology can be comparable to the advanced level of the world.

At present, we are not only promoting the equipment and process that can recover 99.5% (electrolytic) copper online in the production process, but also recycling the waste from solid waste and liquid wastewater into economic or usable copper, glass fiber and epoxy resin powder or solution.

Expired printed circuit boards are difficult to degrade. Difficult to handle, containing heavy metal pollutants, their random disposal will cause PCB pollution,

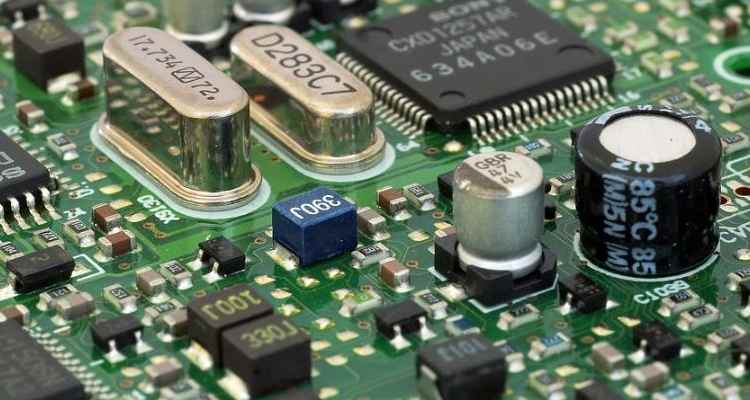

The design and production of printed circuit board is mainly to remove excess copper on the copper-covered board and form a circuit, multilayer printed board also needs to connect the conduction of each layer. As the circuit board is more and more fine and small, so the processing accuracy is improving day by day, resulting in more and more complex printed board production. The production process has dozens of steps, each of which involves chemicals entering the wastewater. The pollutants in printed circuit board design and production wastewater are as follows:

1, copper. Because the excess copper is removed on the copper-covered plate and the circuit is left, so copper is the main pollutant in PCB design wastewater, copper foil is the main source. In addition, due to the double panel, multilayer plate each layer of the line needs to be switched on, in the substrate drilling and copper plating, so that each layer of circuit on, and in the substrate (generally resin) on the first layer of copper plating and the intermediate process and electroless copper plating, electroless copper plating using complex copper, in order to control the stable copper deposition rate and copper deposition thickness. ED TA-Cu(sodium copper ethylenediamine tetraacetate) is commonly used, but also has unknown components. The cleaning water of the printed board after electroless copper plating also contains copper complexation. In addition, printed board production is also nickel, gold, tin and lead plating, and therefore contains these heavy metals.

2, organic matter. In the production of circuit graphics, copper foil etching, circuit welding and so on, the use of ink will need to protect the copper foil part covered, after the completion of it will be returned, these processes produce high concentration of organic matter, some COD up to 10 ~ 20g/L. These high-concentration wastewater accounts for about 5% of the total water volume, and is also the main source of COD in printed board production wastewater.

3. Ammonia nitrogen. According to different production processes, some processes contain ammonia, ammonium chloride and so on in the etching solution, which is the main source of ammonia nitrogen.

4. Other pollutants. In addition to the above main pollutants, there are acid, alkali, nickel, lead, tin, manganese, cyanide ions, fluorine. In the printed board production process using sulfuric acid, hydrochloric acid, nitric acid, sodium hydroxide, a variety of commercial liquid such as etching solution, chemical plating solution, electroplating solution, activation solution, prepreg solution and dozens of other, complex composition, in addition to most of the ingredients known, there are a small number of unknown ingredients, which makes wastewater treatment more complex and difficult.