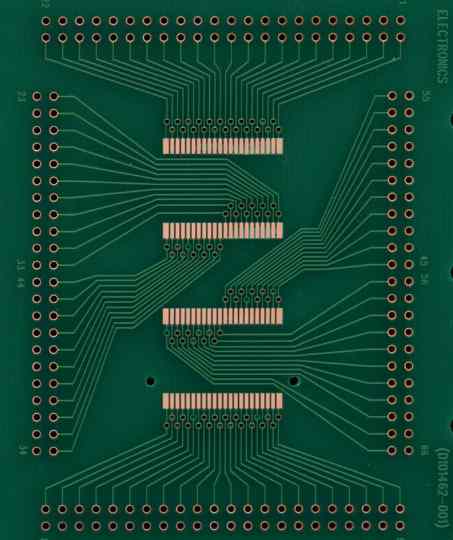

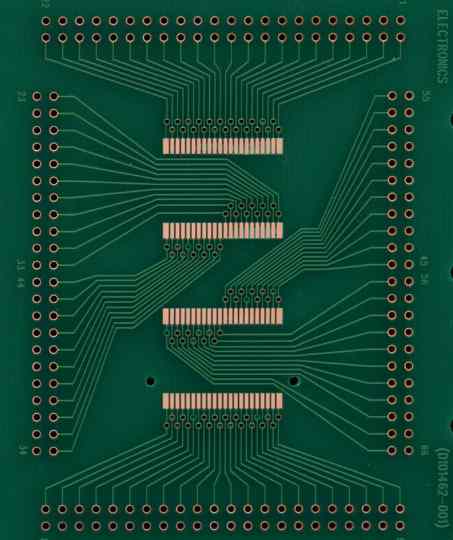

Proofing circuit board according to the number of layers can be divided into different levels, such as: single and double panel, four layers of board, six layers of board, eight layers of board, ten layers of board and so on, different circuit board proofing manufacturers are not consistent prices, the following Xiaobian to introduce in detail.

The factors that affect the price

1. Surface treatment

PCB proofing common surface treatment process is spray tin, gold, gold, OSP, etc., the conventional default surface treatment is spray tin process, gold/gold basic in the conventional process plus 100 yuan.

2, line width moment

The minimum moment between conductors shall not be less than 3mil, and the minimum moment of line width shall not be less than 4mil. The wider the moment between conductors/line width, the higher the yield. The aperture size of mechanical drilling shall not be less than 0.15mm, laser drilling shall not be less than 4mil, and the aperture tolerance is usually controlled within 0.05mm.

3. Thickness of copper foil

The conventional default thickness of copper foil is 1oz, the thicker the foil the more expensive.

PCB proofing price

Circuit board proofing is divided into special price board and non - special price board.

1, special price board standard

The board layer is single and double panel, the material is FR4, the size of length and width is less than 10*10cm, the board thickness is required to be between 0.8 and 1.6mm, the process is required to be ordinary tin spray, the ink color is green oil and white characters, the quantity is less than 10PCS, the minimum line width and line distance is 0.15mm/0.15mm, the minimum aperture is 0.3mm.

As long as meet the above special price of standard pcb board proofing prices are 50 yuan, no free shipping.

2, non-special price board standard

The board layer is single and double layer, the material is FR4, the size of the length or width has exceeded 10cm on one side, the board thickness is required to be between 0.8-1.6mm, the process is required to be ordinary tin spray, the ink color is green oil and white characters, the quantity is less than 10PCS, the minimum line width and line distance is 0.15mm/0.15mm, and the minimum aperture is 0.3mm.

As long as the length or width of any side is more than 10cm, the circuit board proofing fee should be implemented according to the following. The engineering fee is 50 yuan + board fee

Multilayer circuit board proofing price

According to the wiring surface of the circuit board to determine the process difficulty and processing price, ordinary circuit board is divided into single-sided wiring and double-sided wiring, commonly known as single panel and double panel.

But the electronic products, due to the constraints of product space design factors, in addition to the surface wiring, the internal layer can be superimposed, in the production process, the production of each layer of line, and then through the optical equipment positioning, pressing, so that the layer of line superimposed in a piece of circuit board. Commonly known as multilayer circuit board. Any circuit board greater than or equal to 2 layers, can be called a multilayer circuit board. There are many friends who are not very clear about the proofing of multilayer circuit boards, the following Xiaobian to say in detail.

Multilayer circuit board proofing price

0.5㎡ for the model, charge standard: square meters area times the unit price (less than 0.2㎡ according to 0.2㎡ charge)+ engineering fee

1. The unit price of four layers of board is 1000 yuan per square meter, and the engineering cost is 400 yuan.

2. The unit price of six layers of board is 1300 yuan per square meter, and the project cost is 800 yuan.

3. The unit price of eight layers of board is 1800 yuan per square meter, and the project cost is 1200 yuan.

In order to know the price, you must first calculate the number of square meters, in addition to small holes, half holes, blind holes, these need to be calculated in addition, the above is only the approximate price, if you need accurate price, you must be subject to the data.

Precision pcb PCB proofing manufacturers recommended

When selecting PCB proofing manufacturers, PCB purchasers generally choose targeted manufacturers by comparing the overall needs of the factories. PCB boards produced by professional manufacturers are more affordable and have strong quality assurance, and their after-sales service is more guaranteed. Therefore, buyers will choose enterprises with strong mass production and service capacity to reduce the overall risk.

For pcb circuit board procurement, it is not easy to find the right pcb manufacturers, so how to choose PCB manufacturers? What kind of manufacturer recommend it, the following Xiaobian to say in detail.

pcb board proofing manufacturer recommended

One: pay attention to the range of process capacity

When selecting PCB pcb proofing and customization companies, try to choose PCB enterprises with a wide range of processes and rich process capabilities, so as not to delay the process involved beyond the capacity of the circuit board factory, thus affecting the delivery time. Therefore, when selecting a factory, it is necessary to firstly refer to the detailed process requirements, so as to prevent the electrical function from being affected due to the insufficient process.

Two: pay attention to whether the production equipment can meet the requirements

Due to the different types of pcb circuit boards, the production requirements are quite different, and the equipment levels used are also different. Therefore, when selecting customized circuit board manufacturers, we need to make samples first and then consider batch cooperation.

Three: pay attention to whether there is a patchwork cross clause

Due to the particularity of customized processing of circuit boards, all pcb circuit boards that need to be assembled and shipped have the probability of scrap. Generally, customers accept the terms of splicing of the board by default. If they do not accept, they need to communicate with the processing party.

Four: pay attention to whether the company's products have quality assurance

As for the quality assurance product, when selecting the manufacturer, it is necessary to first judge whether the manufacturer has the certificate of quality supervision system. For example, whether the pcb processed products have been tested by flying needles before shipment, so as to avoid the impact of quality problems on the later use of the pcb board and prevent subsequent safety problems.

Here Xiaobian recommend Shenzhen Chengxuan Circuit Technology Co., LTD., they focus on double-sided pcb board, four-layer pcb board, multi-layer pcb board production, alleto can be 8 hours fast delivery, batch can be 48 hours fast delivery, on time delivery rate of more than 98%.

The company depends on the quality of survival, the speed of development, management for efficiency, service for eternal spirit of enterprise. Adhering to the enterprise philosophy of competition, innovation, cooperation and win-win, we sincerely serve customers, adhere to the quality and benefit oriented development road, and strive to make contributions to the electronic industry.