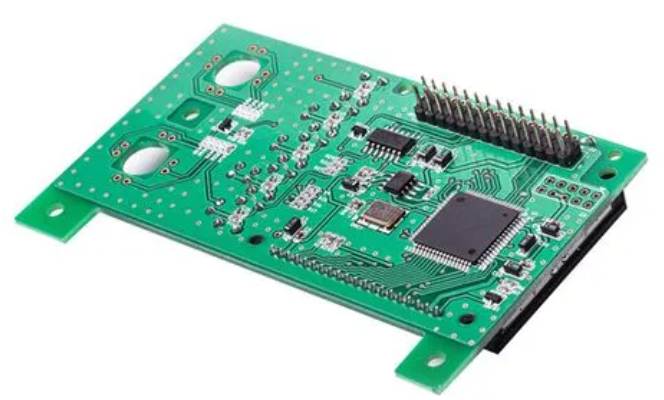

Nowadays, patch generation processing has been a very common thing, many electronic manufacturers in order to ensure product quality, save costs will choose high quality generation processing manufacturers as the object of cooperation, hoping to improve the profit point of their products. However, although the patch processing manufacturer is excellent, it does not mean that the electronics factory can do nothing. On the contrary, when choosing, we also need to pay attention to the following aspects. Below, the patch processing manufacturer will tell you what matters to pay attention to in the patch processing and where the high-quality smt processing manufacturer has the relevant knowledge.

1. Where is the high quality smt manufacturer

Because there are so many smt manufacturers, enterprise customers will always be troubled when choosing. For this situation, Xiaobian has done a survey and summary, and the following will be shared with you, hoping to help friends who want to know where the high-quality smt manufacturers have them. Therefore, if you want to find a quality manufacturer, you must follow the following points:

First, it does not matter whether the scale is large, the key is suitable

Before, many people misunderstood the choice of high-quality smt manufacturers, believing that as long as the scale is large, it must be good. This does have a great reference value, but it is not absolute, and large-scale SMT manufacturers may not be suitable for all corporate customers. On the one hand, some enterprise customers need to make small-batch sample orders, which do not need to find large-scale manufacturers. On the other hand, large-scale smt manufacturers often charge high fees, and the order quantity is large and the queuing time is long. Therefore, instead of this, it is better to directly choose suitable for their own enterprise production of smt manufacturers. Although the scale of these manufacturers is not as large as the processing plant, but they each have their own advantages, each has their own strengths, and their good fields are targeted, suitable for specific production enterprises.

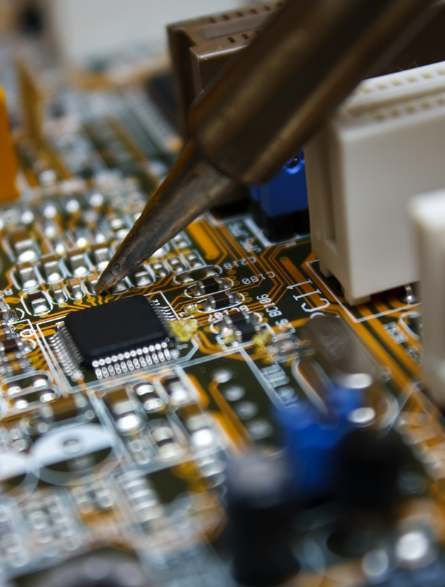

Two, excellent is not excellent, look at the equipment

High-quality smt manufacturers are generally divided into two kinds, one is to take high-end precision route, the other is to take low-end cheap route. The former is often large-scale, large input processing plant, the latter is more in small workshops, individual entrepreneurship, only the machine, not many employees, equipment is relatively old do not say, there is no warehouse pipe, more no quality assurance, only boot and play two kinds of operation, very simple, the price is also very cheap. Of course, the quality of such a small workshop is difficult to guarantee, if it is a high precision added value of the board, must not choose this, otherwise it will regret.

Three, choose not to choose to see the degree of professional cooperation

As an important part of electronic products, the professional cooperation of smt manufacturers determines whether the circuit board can be delivered on schedule, how much repair rate and how much product quality rate. Therefore, if you want to find high-quality smt manufacturers, you must find a high degree of professional cooperation. So, how to judge the degree of professional cooperation? We can observe the attitude and philosophy of SMT manufacturers by talking with their management, bosses and employees, learn about their market reputation through the third party, and learn about their services through the customers we have served.

Four, quality management

In addition to the above three points, there is another important point is to judge whether the manufacturer is excellent basis, that is, quality management. At present, in order to attract customers, some SMT processing plants will attract customers' attention and sign orders with low prices. However, in order to ensure their own profits, they will find a balance from other aspects, such as reducing QC personnel, not equipped with AOI and other detection means, which will lead to the quality of circuit boards will be reduced. Therefore, when choosing high-quality smt manufacturers, we must pay attention to the fact that only comprehensive understanding can ensure the perfect processing of products, improve the performance and service life of products, and gain favorable market.

2. What should we pay attention to in patch generation processing

I. Price

In fact, many electronic manufacturers know this problem, but they cannot stop some people want to produce at a low price. They only see the price, but ignore the value behind the price. As a result, when choosing patch OEM factories, they miss many quality manufacturers because of the price. For this practice, Xiaobian is not agree, because price does not represent everything. While price can be a measure, it is not the only one. Especially now, in order to attract customers, many businesses will use low prices as promotion points to attract customers' attention and cooperation, and then achieve profits through other means. Such a practice is not desirable, will also bring great adverse impact on the enterprise. The best way is to refer to the price, focusing on the cost performance. For example, there are many kinds of materials used in patch generation processing, which can be roughly divided into ten categories. The requirements of these ten types of processing are not the same. Those with high precision must use high-precision equipment, and the mold and forming process have strict requirements, so the cost is certainly not low. Simple price to choose, it is likely to lead to unqualified production, quality is not up to standard.

Two, choose one or choose more than one? If you are asked to find a patch OEM, will you choose a complete or choose a number of companies together to complete? In the small edition survey data found that 40 percent of people back to choose more than one cooperation, about 50 percent of people will choose a contract. Compared with the former, the latter has more obvious advantages.

1, once this batch of products appear quality problems, do not have to go to each one, only need to find this can, responsibility is clear.

2. Save money, because it is a one-stop service, a contracted patch processing plant often gives preferential treatment to electronic enterprises, and a number of cooperation, although it seems that the price is low in stages, it is not low in summary. Therefore, a contract is more economical.

3, production efficiency, the exclusive contract of the processing plant can ensure the quality and quantity of delivery on time, and the separate cooperation of the enterprise, may be due to the delay of a company can not lead to timely processing, resulting in losses. The above two points are the most should pay attention to the patch processing, it is not only related to the reputation of the enterprise and product quality, brand, more related to the future development of the enterprise. Therefore, if you want to find patch processing manufacturers, you must find professional quality, one-stop service, so as to save time and effort, but also to ensure the quality.