1. Rework is also called repair, but it is somewhat different from the repair in SMT patch processing. Let kingford introduce the rework process in PCBA:

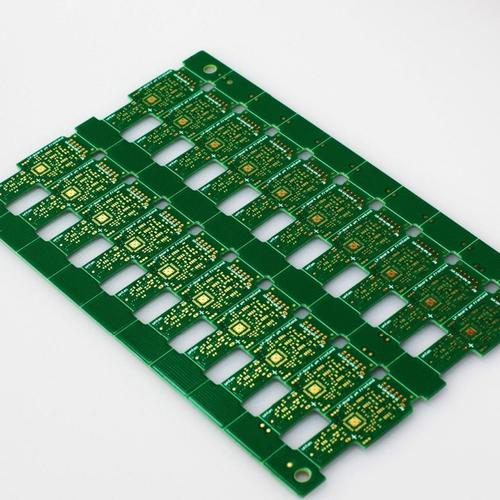

PCBA

First, the difference between rework and maintenance

Rework generally refers to the reworking of nonconforming products by using the original SMT process or replacing the SMT process, and ensuring that the quality is in full conformity with the requirements of the drawings or technical specifications. Repair is the action of restoring the function of the defective product without ensuring that the repaired product conforms to the drawings or technical specifications.

Rework is not a standard process, basically the finished product for certain problems.

Ii. Rework process objectives

1. Controllable, reliable and repeatable process, which can be adjusted when necessary.

2. Efficient process, which can be carried out quickly and easily in the production environment.

3. Non-destructive process: In any rework process, PCB, adjacent components and components to be dismantled shall not be damaged.

Three, rework procedures

Rework includes replacement of components, including removal of components, arrangement of pads, installation of components three basic procedures, sometimes also need to consider the structural parts of electronic components, digital coating removal and replacement, etc.

2. Hand welding beginners, to learn the method

In pcb circuit board manufacturers, circuit board welding generally includes reflow welding, wave soldering and electric soldering iron welding. Reflow welding and wave soldering belong to automatic welding, which is less affected by human factors. Electric soldering iron welding belongs to manual welding, which is more affected by human factors. The following let Shenzhen kingford Co., Ltd. to introduce the use of electric iron on the circuit board manual welding matters needing attention:

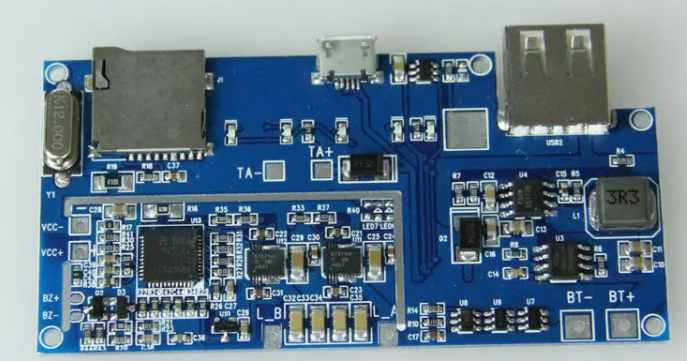

Circuit board

1. Make full use of dual panels

Each pad of the double panel can be used as a hole to flexibly realize the electrical connection between the front and back.

2, choose the right welding temperature

The welding temperature of electric soldering iron is too high or too low, it is easy to cause poor welding.

3. Welding components follow the principle from small to large

The components should be welded small first, then large.

4. Pay attention to reverse polarity

Like some capacitors, resistors, diodes and triodes, are polar direction, in the welding to avoid the reverse connection.

5. Make the most of the space on the board

If it is a development board, you can hide the holes and small components under the larger chip, but this is generally not recommended because it is difficult to fix problems during subsequent maintenance and inspection.

6, tin is not easy to too much

When welding, we should ensure that there is tin around the solder joint to prevent virtual welding, but it is not the more tin the better, when the solder joint tin cone layer is the best. When welding the circuit board, it is also necessary to pay attention to ventilation. You can choose to equip an extraction fan to prevent the gas generated during welding from being inhaled into the human body and causing harm to the human body.

The above is about "if you are a hand welding beginner, must learn these methods" introduction, I hope to have some help to you.