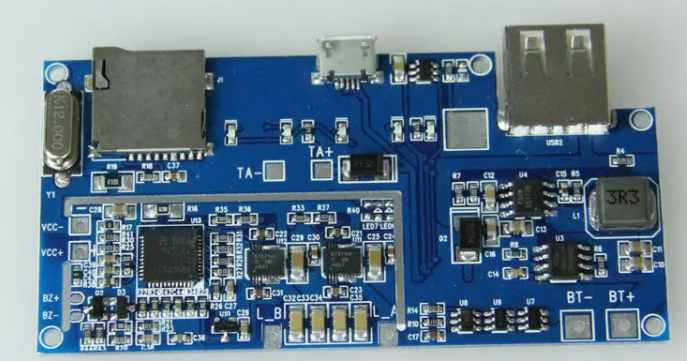

PCBA is the abbreviation for the English Printed Circuit Board +Assembly, that is to say, PCB empty board through the SMT, and then through the whole process of DIP plug-in, abbreviated PCBA. This is A commonly used writing method in China, and the standard writing method in Europe and America is PCB 'A, which is added with oblique points. This is called the official idiom, when we communicate or promote with overseas customers, they will occasionally ask what PCBA means.

Both SMT and DIP are in the form of integrated parts on PCB board. The main difference is that SMT does not need to drill holes on PCB, and the PIN of the parts is inserted into the drilled holes in DIP.

SMT (Surface Mounted Technology)

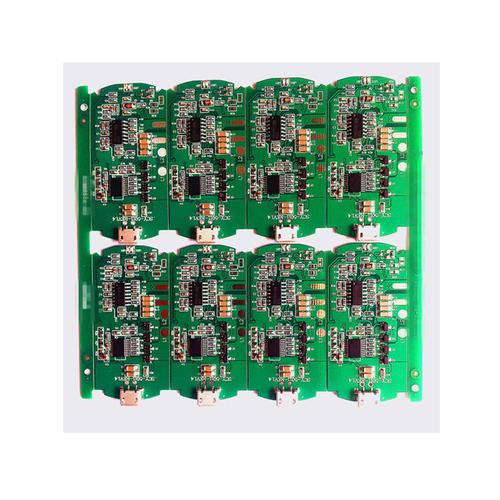

External mounting technology, the main use of mounting machine is to mount a small scale of parts on PCB board, its production process is: PCB board positioning, printing solder paste, mounting machine, back welding furnace and made inspection. With the development of science and technology, SMT can also mount some large-sized parts. For example, some large-sized mechanism parts can be mounted on the main engine board.

During SMT integration, I am keen on positioning and size of parts. Besides, the quality of solder paste and printing quality also play a key role.

DIP refers to "plug-in", that is, parts are inserted into the PCB version. Due to the large size of the parts and the discomfort, the parts are suitable for mounting or if the manufacturer thinks it is appropriate to use SMT technology in the production process. Up to now, there are two successful forms of artificial plug-in and robot plug-in in the industry. The main production process is: stick back glue (to avoid tin plating to the place where it should not be), plug-in, inspection, soldering, brush version (remove the stain left in the process of furnace) and made inspection.

PCB (Printed Circuit Board), Chinese name for printed circuit board, also known as printed circuit board, is a closed electronic device, is the support body of the electronic component, is the electrical component of the carrier. Because it is made using electronic printing as it sees fit, it is called a "printed" circuit board.

Electronic facilities think appropriate and use of printed board, because of the same type of printed board, so prevent the error of manual wiring, and can successfully achieve electronic components semi-automatic insertion or paste, semi-automatic solder, semi-automatic inspection and determination, to ensure the quality of electronic facilities, increase the labor production rate, reduce the cost, and easy maintenance.

PCB have gained ever wider use because they have many unique and special advantages, including the following.

Can be high density degree. Over the decades, the high density of printed boards can be improved with the increase of integrated circuit integration and the improvement of installation technology.

High reliability. After a series of investigation, testing and aging attempts, the PCB can be guaranteed to work reliably for a long period of time (usually 20 years).

Presupability. For PCB various performance (electrical, physical, chemical, mechanical, etc.) requirements, can be preset standardization, standardization, etc., to successfully achieve the printed board preset, short time, high speed.

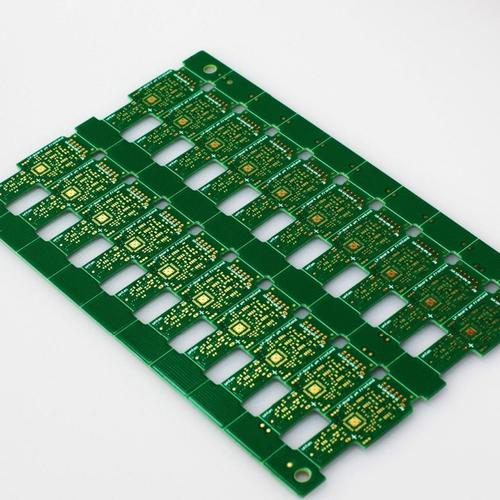

Productability. Think that appropriate and the use of modern management, can implement standardization, scale (quantity), semi-automatic production, to ensure that the production quality and quantity is exactly the same.

Testability. A more complete test method, test standards, various test facilities and spectrographs have been set up to test and determine the conformity of PCB products to the standard and the life of use.

Assemblability. PCB products are easy to implement standardized assembly of various components, but also can implement semi-automatic, large-scale production. At the same time, PCB and various component assembly devices can also be assembled into larger devices, systems, until the whole machine.

Protectable. Because PCB products and various component assemblies are produced in standardized presets and at scale, these components are also standardized. Therefore, once the system fails, it can be implemented quickly, conveniently and flexibly, and the system office can be quickly restored. Of course, there could be more examples. Such as the system small scale, lightweight, signal transmission high-speed, etc.

There's a finished board and there's a bare board

PCB is made of epoxy gas glass natural resin material, according to the number of signal layers is different into 4, 6, 8 layers of board, with 4, 6 layers of board is the most common. Chip and other patch components are attached to the PCB.

PCBA may be known as finished circuit board, that is, the ability to calculate PCBA after all the processes on the circuit board have been completed.

PCBA=Printed Cirruit Board +Assembly.

That is to say, PCB empty board through SMT, and then through the DIP plug-in of the whole process, referred to as PCBA.

A standard PCB with no parts on it is also often referred to as a "Printed Wiring Board (PWB)".