PCB manufacturing is the transformation of a circuit board design into a physical PCB that complies with the design specification. Outsourcing is usually done by a contract manufacturer (CM) who strictly follows the specifications provided by the designer. Certain key factors (such as PCB substrate selection, layout strategy, surface coating requirements) are determined prior to manufacturing and these factors may affect manufacturing yield and product performance. Therefore, it is important for any PCB designer and manufacturer to understand the PCB manufacturing process and its trends.

The growing demand for digitization in consumer and industrial electronics has driven many innovations in the PCB manufacturing process. Advanced PCB substrate materials such as epoxy resin and polyamide meet the development needs of the global PCB market. Recycling of PCBS is now being widely looked at to meet environmental and sustainability guidelines set by government authorities.

The communications and automotive industries are the major applications driving the global PCB market. Technologies such as artificial intelligence, Internet of Things and 5G mobile communication are also affecting PCB manufacturers, bringing about a revolution in PCB design and manufacturing technology. We will look at the latest PCB design and manufacturing trends.

1, flexible printed circuit board

One of the fast growing trends in PCB manufacturing is the use of flexible PCBS because they can be changed to any shape or size. Advantages of flexible PCBS include smaller size, greater flexibility, and a variety of substrate options. These characteristics make them best suited for medical, wearable, and other application-specific requirements. Besides Flex PCBS, there is Rigid-flex PCB for compact product development.

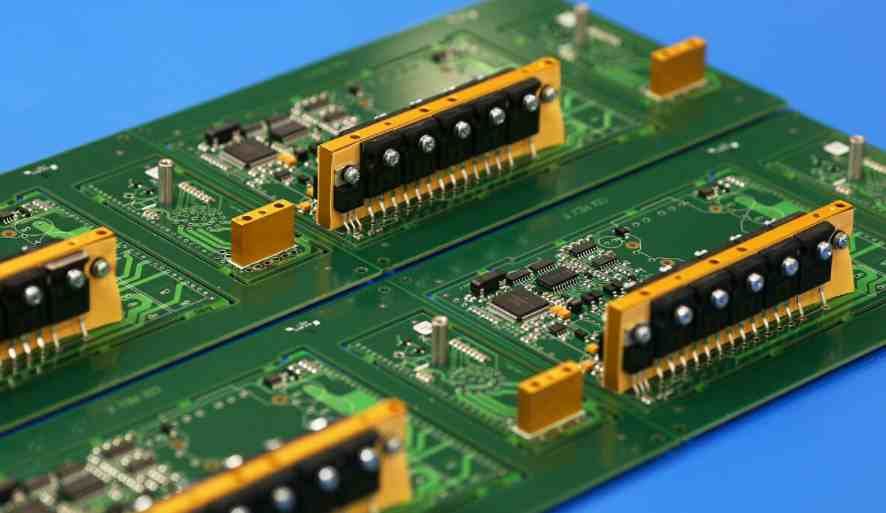

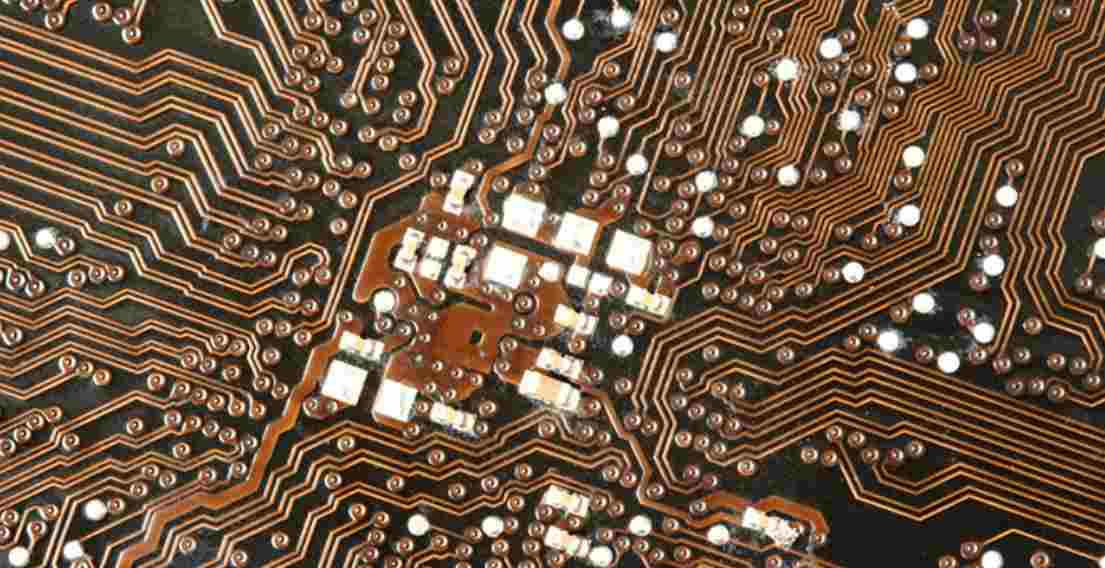

2. High density interconnection

Automation in every field is leading to an increased demand for high density interconnected (HDI) PCBS because they provide reliable and high speed signal transmission. HDI PCBS provide a smaller path width, thus increasing the wiring density. The reduced PCB layers also reduce production costs. As such, HDI PCBS are critical in intelligent applications such as aerospace, medical and wearable technology devices.

3. High power PCB

With the focus on renewable energy sources such as solar power, demand for high-power PCBS is growing substantially. Most solar panels operate in a voltage range of 24 V to 48 V. In addition, electric vehicles also increase the demand for high power board. Accommodating long-lasting battery packs will allow products to run longer, which requires high-power circuit board designs with efficient heat dissipation.

4, PCB automatic paste machine

PCB design techniques also optimize efficiency through the introduction of automatic layout and routing in EDA tools. This automation is speeding up design time-to-market and improving quality. Going forward, CAD systems will be integrated with processes to improve design and simulation speed.

5. Demand for smart devices

With the trend of smartphones connecting to smart homes or smart offices, the demand for smart devices is growing. Such applications require devices that are scalable and securely connected. This could be a huge source of revenue in the future and therefore requires PCB manufacturers to be flexible and adaptable to capture the market.

6. COTS components

These are off-the-shelf products for commercial applications, fully or partially designed and assembled products to speed up the design process and other benefits. Because they meet strict standardization and regulatory guidelines, they are an excellent choice for critical and space-based systems. In addition, they provide reliability and efficiency at a lower overhead. The aerospace industry uses COTS components extensively, and other areas may soon catch on.

7. Parts supply chain control

As new applications emerge, there are many opportunities to introduce new components. There is a growing need to avoid counterfeit components from the supply chain. This is essential for critical applications such as medical devices, artificial intelligence and virtual reality. New PCB manufacturing methods are needed to control the problem, such as implanting a microchip inside the component to prevent counterfeiting.

8. PCB of Internet of Things

Iot devices are compact, portable and reliable, prompting PCB manufacturers to adopt security features to prevent tampering. Iot PCBS must comply with specific standards and regulations to comply with the required security.

9. Biodegradable polychlorinated biphenyls

Traditional PCB boardare difficult to treat harmlessly because they contain a lot of non-degradable chemicals. Discarded PCBS contribute to e-waste, increasing global attention to e-waste management. Biodegradable polychlorinated biphenyls (PCBS) are the key to solving this problem, as well as the recycling of PCB scrap metal.