Evaluate whether the processing ability of a PCBA manufacturer is excellent, you can make a preliminary judgment through the qualification certification obtained by PCBA manufacturers and the technical strength of equipment capacity. Below, we will analyze in detail what qualifications and technical strength of PCBA manufacturers are the most important.

1, basic qualification certification (ISO9001 certification, CCC certification)

PCBA manufacturers have two most basic certification, one is ISO9001 certification, ISO9001 certification is the national minimum for PCBA processing industry a basic specification requirements, is also the industry standard, only obtained ISO9001 certification, the country will recognize your products, ISO9001 certification includes the product production environment, technology, process and other links.

The other is CCC certification, if the PCBA processing product category belongs to the mandatory certification range, also must have CCC certification, the product can be normally sold on the market.

ISO9001 certification and CCC certification are the most basic qualifications for PCBA manufacturers.

2, strength qualification certification (ISO13485 certification, IATF16949 certification)

When the processing capacity of PCBA manufacturers reaches a certain level, they will come into contact with some special customers, such as medical, automotive, aerospace, military and other industry customers. At this time, PCB processing plants need to obtain the corresponding qualification certification, in order to better serve customers. For example, if you want to do medical industry, you need to obtain ISO13485 medical quality management certification. The automotive industry needs to obtain IATF16949 automotive electronic quality management certification.

ISO13485 and IATF16949 relative to ISO9001 and CCC certification of PCBA manufacturers will be higher and more strict requirements, especially document control, record control, meeting training, infrastructure maintenance, working environment, risk control and so on.

3. Export Qualification Certification (UL Certification)

If the PCBA manufacturer has overseas customers, it needs to obtain a UL certification. The UL certification is the product certification that allows the product to be exported to the United States or Canada. If there is no UL certified PCBA manufacturer, the product cannot be exported.

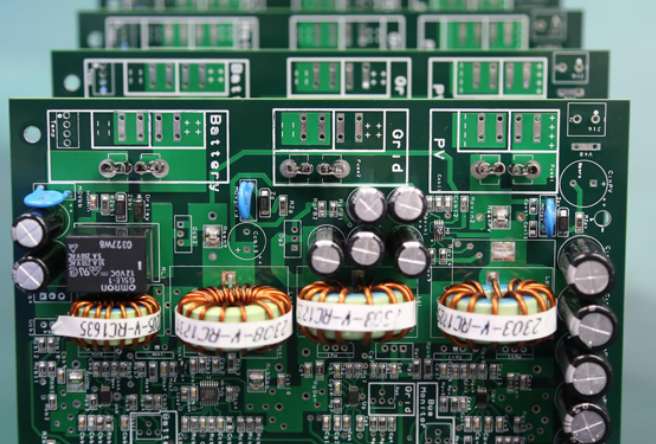

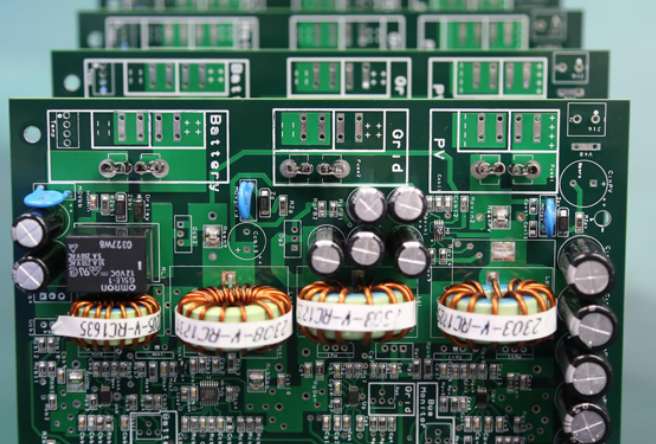

4. Technical strength (hard strength: equipment capacity)

The best manifestation of our technical strength is that we can do the orders that other PCBA manufacturers cannot do, and solve the problems that other PCBA manufacturers cannot solve. Technical strength requires excellent equipment support, so PCBA manufacturers must be equipped with fully automatic high-speed printing press, AOI optical detector, DIP plug-in line, ICT/FCT test line, three-proof paint coating line, finished product assembly line, to meet all the requirements of production, testing, assembly. At the same time, we also need to equip a team of engineers to help customers solve technical problems and propose better product solutions.

5. Technical strength (Soft power: service awareness)

In order to become an excellent PCBA manufacturer, qualification certificates and equipment capacity are not only needed, but also the service consciousness of quick response, timely communication, long-term after-sales service, customer-oriented and helping customers solve all problems is the most important.

To sum up, ISO9001 certification, CCC certification is the basic certification of PCBA manufacturers, can obtain ISO13485, IATF16949, UL certification of PCBA manufacturers are more comprehensive strength of the enterprise. Technical strength requires an audit of the equipment capacity of the PCB processing plant, the professionalism of the engineer team, and the service awareness of the docking staff.