At present, all countries in the world have put forward the requirements of lead-free printed circuit board and its assembly. Why is lead not allowed on printed boards, assembly processes and products? There are two reasons for this: first, lead is toxic and affects the environment; Second, leaded solder is not suitable for new assembly technology.

Lead is a toxic substance. When the body absorbs excessive amounts of lead, it can cause poisoning. The main effects are related to four tissue systems: blood, nerves, stomach and kidneys. If there are prone to anemia, dizziness and lethargy, motor disorders, anorexia, vomiting and abdominal pain, and chronic nephritis. Intake of low doses of lead may also have adverse effects on the mental, nervous and reproductive systems.

The use of tin-lead solder coating on PCB board surface can cause harm from three aspects.

1. Lead can be exposed during processing. The processes of contact with lead include plating tin lead in graphic electroplating with tin lead layer as corrosion resistance, removing tin lead after corrosion, hot air leveling solder (spray tin) process, and some hot soldering process. Despite the production of exhaust and other labor measures, long-term contact will inevitably suffer.

2. Lead-bearing wastewater such as tin and lead electroplating, and lead-bearing gas in hot air leveling (tin spraying) have an impact on the environment. Lead-containing wastewater comes from electroplating cleaning water and dripping or discarded tin and lead solution. It is often considered that the amount of wastewater in this respect is small and water treatment is difficult, so it is not treated and put into a large pool to discharge.

3. Printed boards contain tin and lead plating/coating. When such printed boards are scrapped or electronic equipment used is scrapped, the lead on them cannot be recycled. If the waste is buried underground, the groundwater will contain lead over the years, which will pollute the environment. In addition, the use of solder solder in PCB assembly wave soldering, reflow welding or manual welding operations have the presence of lead gas, affecting the human body and the environment, while leaving more lead content on the PCB.

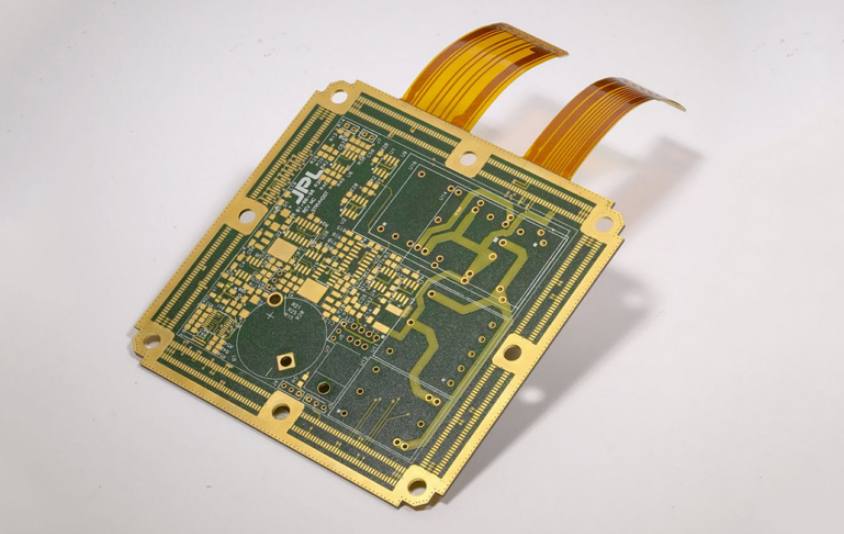

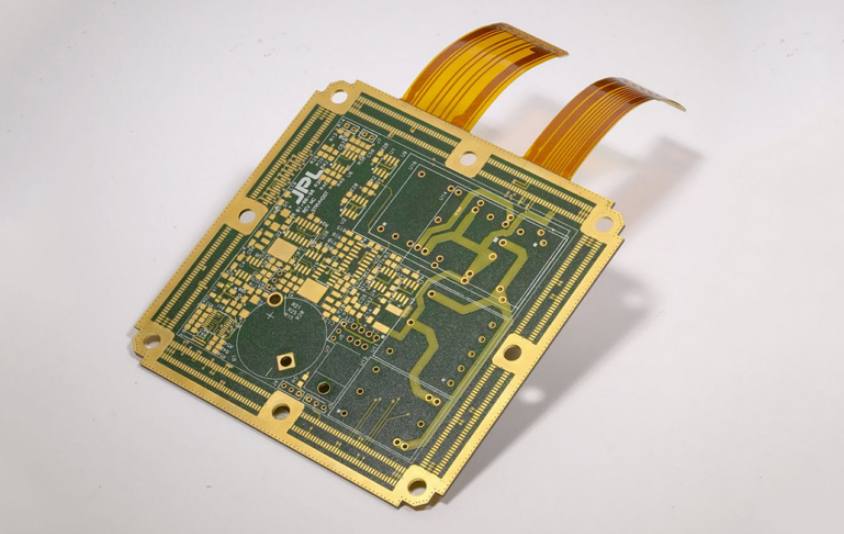

Tin-lead alloy solder as a weldable and anti-oxidation coating is not completely suitable for high density interconnection products. Such as the current printed board surface coating in the world although more than 60% of the use of hot air leveling tin lead, but encounter SMT installation when some small components require PCB board welding plate surface is very flat, and components and PCB connecting plate using non-welding method such as wire joint, hot air leveling tin lead layer is not smooth enough, or hardness is not enough, or contact resistance is too large and other factors, Other coatings other than tin lead should be used.

Lead-free industrial products European countries first proposed, in the world in the 1990s on the formation of regulations to march to lead-free.

The lead-free printing board is fully conditional. At present, in addition to tin lead alloy, the surface coating has been widely used organic protective coating (OSP), electroplating or chemical plating nickel/gold, electroplating tin or chemical leaching tin, electroplating silver or chemical leaching silver, and the use of palladium, rhodium or platinum and other precious metals. In practical applications, the common consumer electronic products with OSP surface finish is suitable, the performance is satisfied and the price is cheap. Nickel/gold coating is widely used in durable industrial electronic products, but the processing process is complicated and the cost is high. Platinum rhodium and other precious metal coating only special requirements for high performance electronic products, good performance and high price. At present, chemical leaching of tin or chemical leaching of silver is actively promoted, which has good performance and moderate cost. It is an excellent choice to replace tin lead alloy coating. Chemical leaching of tin or silver is a simpler and less costly process than chemical leaching of nickel/gold, as well as good solderability and flat surface, and high reliability when using lead-free solder.

Lead-free solder assembly has also been realized for lead-free printed boards. Lead-free solder is still the main component of tin, usually more than 90% tin, plus silver, copper, indium, zinc or bismuth other metals. These alloy solder composition and melting point temperature is not the same, the range can be selected between 140℃ ~ 300℃. From the perspective of adaptability and cost and price factors, the selection temperature of wave soldering, reflow welding and manual welding is different, and the solder composition is different. Currently used solder such as 96. 5Sn over 3. 5Ag, 95. 5Sn over 4. 0Ag/0. 5Cu and 99. 3Sn over 0. The melting temperature of 7Cu is between 210 ℃ and 230℃.