The current wave soldering is usually composed of plate loading system, flux coating system, preheating system, welding system, electrical, mechanical structure system structure system.

The functions of each system are described below

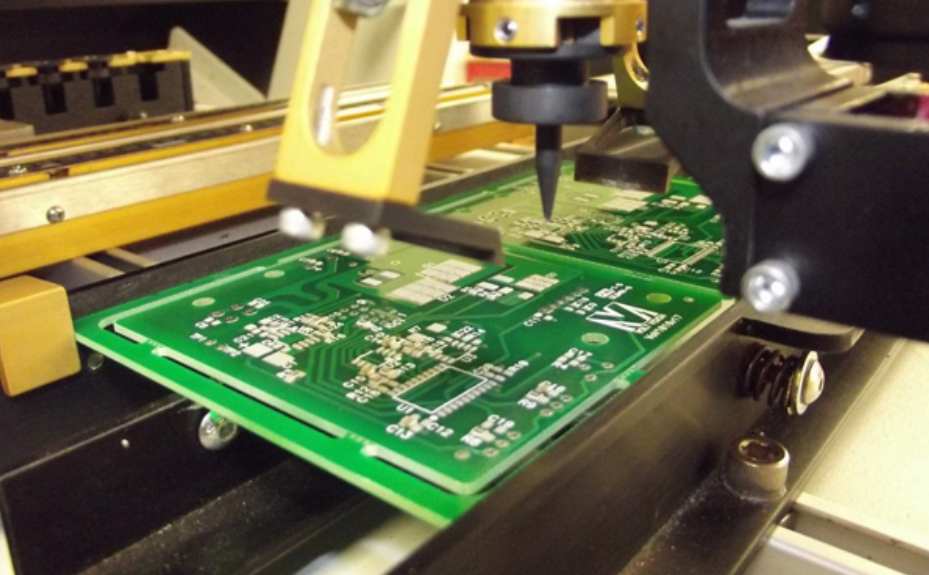

1. Plate loading system

Mainly composed of rail, rail can be mechanical or electric control spacing, the welded PCB board can run smoothly on the rail.

2. Flux coating system

PCB spraying flux, commonly used methods include foaming agent, spray, etc.

3. Preheat the system

Preheating PCB components, high temperature can make the solvent in the flux volatilize quickly and activate the flux, so as to remove the oxidation layer of PCB pad and components welding end, laying the foundation for high reliability welding.

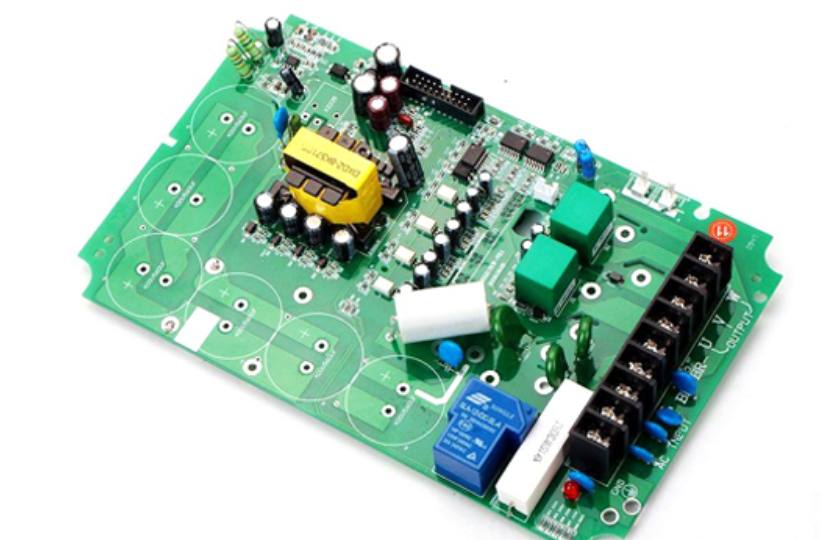

4. Welding system

The welding system is one of the most key of the wave soldering machine, is an important link to complete the welding operation, the basic principle of wave soldering is to catch the stirring effect of the pump in the solder groove, the molten liquid solder form a specific shape of wave soldering, the PCB circuit board of the components is inserted on the conveyor belt, Through a specific Angle and a certain depth of immersion through the solder crest to achieve welding.

Early wave welding machine only one outlet, known as a single wave welding machine, the current use of wave welding machine has two outlets, also known as double wave welding machine, double wave welding machine before the export of the drug tin wave shape pulse upward, its purpose is to let the solder spot rapid temperature rise, while the solder impact in the vertical direction with components of the pad, but at this time has not formed a reliable solder spot, After the discharge port of the double wave flux, the shape of the tin wave is relatively flat, and the solder joint is heated more evenly in the flat tin wave, and the solder joint is moist enough to form a high reliability solder joint. Early flat wave has a variety of different waveforms, some waveforms like the Greek letter λ, known as λ wave, his waveform is flat and open; Some waves look like the Greek letter Ω and are called Ω waves. Ω wave is mainly installed in the solder outlet vibration source, so that the surface of the tin foil produces small amplitude vibration, the use of his oscillation can increase the welding function, promote the solder wet component pin, can effectively solve the problem of welding dead zone. However, the effect is not obvious when the density is too high or the difference between the height of the parts is large, and there are bubbles in the discharge port of the wave welding machine, so it is also called bubble tin wave. His principle is to drive air or nitrogen into a tin pot from under a tin tank, creating a tin wave containing numerous small bubbles. These bubbles emerge upward with the solder, and have higher kinetic energy, so as to break up the gas surrounded by the solder joint, is easier to enter the solder pad. It was designed by the Japanese and is often used in Japan.

Before the use of wave welding machine flat wave is to shorten the main peak of the λ wave, the auxiliary peak extension evolution, which is characterized by the wave crest becomes very wide, so it is also known as T wave,. Printed board through the T-shaped wave peak, solder wet printing board welding area, forming solder joint, hesitate welding peak is very wide, welding time can be guaranteed, solder surface tension has enough time to excess solder completely drag back to the peak surface, reduce the bridge phenomenon.

In some wave welding machines, hot air knife is installed after the wave crest. Hot air at high temperature can effectively remove the solder joint bridge and reduce the thermal stress of the component. After the PCB passes through wave soldering/hot air knife, it quickly enters the cooling zone. At this time, the wave soldering machine is equipped with cooling fan to ensure the PCB is cooled to reduce the damage caused by heat retention.

5. Electrical and mechanical structure system

Electrical and mechanical structure system is the guarantee of effective operation of the above systems. The system of the high performance wave welding machine runs smoothly, quantitative control and high precision, such as preheating temperature, tin pot temperature can reach ±1℃, in addition to the width of the rail, inclination, solder spot depth in the tin wave, residence time can be quantized control.

Crest welding machine, the main station is the welding system, that is, the solder crest and the circuit board contact station, the rest are auxiliary station, but the crest welding machine is a whole, auxiliary station is indispensable or damaged.